Intro/Outro (00:01):

Welcome to TEKTOK, digital supply chain podcast, where we will help you eliminate the noise and focus on the information and inspiration that you need to transform your business, impact supply chain success and enable you to replace risky inventory with valuable insights. Join your TEKTOK host, Karin Bursa, the 2020 Supply Chain Pro to Know of the Year. With more than 25 years of supply chain and technology expertise (and the scars to prove it), Karin has the heart of a teacher and has helped nearly 1000 customers transform their businesses and tell their success stories. Join the conversation, share your insights, and learn how to harness technology innovations to drive tangible business results. Buckle up. It’ time for TEKTOK, powered by Supply Chain Now.

Karin Bursa (01:05):

Welcome back supply chain movers and shakers, Karin Bursa here. I am your host for TEKTOK, the digital supply chain podcast. Thank you for tuning in today. It has been a busy, busy week filled with the 2022 Gartner Supply Chain Symposium.

I wanted to share just a few highlights from the event with each of you. As you know, the expectations around the value supply chains deliver are accelerating despite all of the ongoing volatility, disruption, gridlock, and, of course, uncertainty. We are all grappling with the impacts of the pandemic, even today, global conflict, climate change, new ESG initiatives, shifting channel and product mixes, as well as significant constraints, unavailable talent. As supply chain leaders, we’ve got to be prepared to navigate this uncertainty and mitigate risk. It’s increasingly a dynamic global market, and many of these challenges were discussed, as you can imagine, at the 2022 Gartner Supply Chain Symposium, which was held in Orlando, Florida.

Karin Bursa (02:31):

This Gartner Conference is billed as the world’s most important gathering of chief supply chain officers and supply chain executives. Unfortunately, there were no silvers bullets, but there were a number of insights and plenty of inspiration. Let’s start with the fact that the conference was actually oversubscribed. Now, I don’t have the exact numbers, but I believe that Gartner expected between 1800 and 1900 supply chain practitioners. However, estimates are that registration was closer to 2600. Yeah, let me say that again, 2600 supply chain professionals gathered together in Orlando this week. That meant that there were three overflow hotels in addition to the Dolphin and Swan accommodations that Gartner had planned in the Orlando area. It was really exciting to see so many supply chain movers and shakers together in real life. It felt a little like a reunion, a little like a party, and then some really, really good discussions.

Karin Bursa (03:54):

As we caught up with old friends, connected face-to-face with colleagues that we have only seen in virtual formats for the past two years, and we had the opportunity to meet new supply chain team leaders that are making an impact. Over a three-day agenda, there were more than 140 sessions — many of which were featuring the latest research and insight from Gartner. Try as I did, there was no possible way to cover all of these sessions. So, I wanted to share just a few of the highlights with you. If you were at the conference, please chime in with your highlights, your takeaways. And, if you couldn’t attend the Gartner Symposium, let me know what you found valuable in this recap.

Let’s start at the beginning. The opening keynote was delivered by Gartner analyst, Ken Chadwick, and it focused on this theme of Supply Chain’s Offset Strategy, Recalibrating our Approach to the Great Acceleration.

Karin Bursa (05:02):

Although I didn’t love the term “offset strategy,” but I totally get it, and I’ll explain why. While we have survived some of the most volatile and uncertain times in recent history, I think we all recognize our journey is not done. Our goal is not to simply survive. It is to thrive and to build thriving supply chains. Yes, I’m an optimist. I do like Gartner’s positioning because they said that we were on the cusp of the great acceleration. Now, that can mean a lot of things. And I’m going to tell you, Gartner shared some offset strategies for what they believe to be the five challenges supply team leaders should be addressing. So, five challenges supply chain leaders should be addressing. The first was really interesting. It is cognitive overload. This really focused on the burden and the way that we, as supply chain professionals, feel. Cognitive overload was a recurring theme throughout the conference.

Karin Bursa (06:23):

Gartner shared a statistic that said that a staggering 83% of the workforce, the supply chain workforce, feels overwhelmed. That’s right 83% of us are feeling overwhelmed. If any of you, TEKTOK listeners, you movers and shakers out there, are feeling overwhelmed, you’re not alone. In fact, if you’re NOT feeling overwhelmed, you’re in the minority at this point. Now, one of the key strategies around cognitive overload that was shared by Ken Chadwick was that we need to shift the burden of decision-making to computers or to technology. Now, let me be clear. Gartner was not advocating replacing humans, but instead augmenting humans with better insights, faster analysis, so that we can inspire confidence and quicker decision-making. So, in fact, Ken Chadwick shared one example, which was from Lenovo, and Lenovo has been able to achieve a 55% reduction in decision cycle time. Impressive, right?

Karin Bursa (07:49):

So, Lenovo is making decisions in less than half the time that they used to. And this has helped to contribute to about a $26 million increase from a profitability perspective or profit growth perspective. That’s right. Lenovo making decisions faster to cycle times or contracting, and they can measure that impact with additional profit growth. Now, rest assured, that got the audience’s attention! So, that was the first challenge that Ken Chadwick put before us this audience of 2600 supply chain professionals.

The second is the evolving customer expectations. Each and every one of you are dealing with this whether you’re doing product rationalization or customization. These are trends that will continue, technology change, technology evolution. It’s no secret that technology has been evolving faster than most companies have been able to harness, deploy and use to their advantage. Don’t allow yourself to get stuck because you will get left behind.

Karin Bursa (09:11):

Number four was supply chain cyber risk, a very, very real challenge for many of us in the industry today, and it is high on the list of CEO concerns as well.

Number five is energy instability. Now, here in North America, we are dealing with energy instability or rising fuel costs. Which impact every business and is requiring the ability to replan a number of supply chain initiatives or to re-evaluate margin contributions for customers or product lines or distribution channels as well.

Ken Chadwick asked everyone to look at delivering at least one win in each of these five categories. If you can do one thing in each of these five categories, you will keep pace and thrive.

Karin Bursa (10:19):

So, again, let me give those to you. Cognitive overload, let’s remove some of that burden or accelerate that decision process. Evolving customer expectations, let’s get closer to our top customers. Let’s understand and get greater visibility on how we can serve them. Let’s look at segmentation strategies, technology change. I know it can be difficult, but you must keep pace. You must be looking to adopt harness, deploy AI-driven capabilities so that you can make decisions faster or evaluate criteria faster. Be sure that we are considering supply chain cyber risk and then looking at strategies around energy instability. Let me know if I’ve overwhelmed you. And, if you’re tuning me out, thinking, Karin, what am I going to do? Those are our big, big rocks to be moved. Stay with me! I want to share some inspiration as we go through this recap.

Karin Bursa (11:22):

So, there was another session that Ken Chadwick on CEO concerns in 2022 and 2023. This is what your CEO is thinking about or what the aggregate survey shows that CEOs are concerned about and the implications and actions for supply chain executives or chief supply chain officers. I picked a few of these. The first is growth. As long as I have been tracking this, growth is always number one on a CEO’s agenda. And it is still in fact a number one priority for the CEO despite expectations that inflation is going to continue for (potentially) as long as three years. So, be sure that when you’re engaging with your CEO or your executive team, you are presenting ways that you and the supply chain team can fuel growth, anticipate growth, serve customers from a growth perspective, or even tap into new markets.

Karin Bursa (12:42):

Number two on the CEO’s priority list was technology related. CEOs see digital strategies as key solutions to boost productivity and manage costs. That should not be a surprise to you, but it was number two on this CEO survey. How do we harness it, how do we use it, how do we boost our corporate digital strategy to increase productivity and manage overall cost. At number three was workforce. This moved up from number five in the prior 2021 survey. Priorities need to be realigned to attract and retain talent. That’s right. No surprise. You’re probably going, tell me something I didn’t know, Karin! Well, they rolled in the need to expand diversity and inclusion efforts as well. So, bringing in the DEI initiatives as a part of attracting, retaining, challenging, giving opportunities to your workforce is number three on the CEO’s list. In the past, this has been around number five.

Karin Bursa (14:12):

Now, another one that made a big move, is environmental sustainability. This moved up to number seven. Prior year, it was at number 17, so that’s 10 positions. This does reflect a change in the buyers in the marketplace. Today’s consumers/buyers that are coming into power and authority and businesses or consumers that have more income to spend and they want products that reinforce a strong environmental message to the marketplace, sustainability message in the marketplace, good governance of how the products are developed, the materials used, and how they make their way to market even the packaging that surrounds the product as it makes its way in either a B2B or a direct-to-consumer. So, CEOs now agree this is a worthy investment, and it will actually fuel future revenue and sales.

Karin Bursa (15:24):

Now, supply chain improvement, just as a broad theme for these CEOs, was number 11. I’ve got to tell you, this surprised me! On prior years, it has been around number 14. But I was surprised it wasn’t higher for 2022. It didn’t break the top 10 themes. Supply chain improvements landed at number 11. Let me know what you think about that.

Now, with this digital accelerated decision-making, there was one session that caught my attention based on title alone. The title of this session was – let me look at this and get it right for you. The title was the Digital Era and the End of S&OP? Now, it had a question mark at the end. So, the end of S&OP? Maybe I need to say that differently, the digital era and the end of S&OP, with a big question mark. This was delivered by Gartner Analyst, Pia Lund.

Karin Bursa (16:27):

I was on the edge of my seat because you know the topic of sales and operations planning is one that I have a great deal of expertise and passion around. While analyst, Pia Lund got down to brass tactics and told a standing room only audience the technology has evolved faster than our S&OP process and it’s time to make a change. She advocates that S&OP should be sure to align to business objectives instead of rigid time horizons, business objectives, overall goals and objectives, not just that we have a monthly planning cycle or a quarterly planning cycle, or we’re looking at investments on a three-year horizon. Secondly, she advocated that we leverage systems that evaluate hundreds of scenarios versus just a few. That’s right, hundreds of scenarios! This is a great example of taking advantage of technology to cycle through the available data, the business context, and then present up the best or the most likely scenarios to be discussed in your executive S&OP leadership team. I love this!

I’m seeing this take place today. For those of you that are looking at best case, worst case, and most likely scenarios, a three-pronged evaluation, you need better data and faster analysis. You need the ability to kind of boost the confidence and look at a tighter range of outcomes and have the understanding that there were literally hundreds of business scenarios that were evaluated to present those to you.

Then the final theme that she spoke to was that we need to focus on the future versus the past. I really believe this. We’ve got to get out of that firefighting mode. We do need to measure the performance of our plans. At the same time, we need to be getting smarter and smarter and learning what went well and what didn’t go well, right? With machine learning coming into play, you can evaluate what we did and what the impact of that was.

Karin Bursa (18:58):

So, here are a few examples that Pia Lund offered as examples of shifting in the way you are looking at your planning around sales and operations planning.

We need to go from siloed decision-making to broad alignment with our business strategy. Everybody, every one of you should be nodding yes as you’re listening to this. So come back to me, stay with me on this list. We want to move from looking only at a few constraint considerations to many, many constraint considerations. In fact, you may want to include personnel, your talent pool, as part of your constraints that are being modeled today. Move from those one to three scenarios to the ability – I said the ability to look at hundreds of scenarios. She actually said thousands of scenarios. That’s right, thousands of scenarios. Clearly, we need to get well beyond the one, two, threes and strive for, you know, hundreds and potentially looking at thousands of scenarios for our business.

Karin Bursa (20:12):

She also mentioned that we need to stop thinking of our ERP systems, our enterprise resource planning systems, as the single source of data. We need to start tapping into external data sources and extending those so that we’re getting better signals, sensing demand from multiple signals, but also sensing supply and looking at those signals to really augment and improve our overall planning. We’ve got to move from batch planning, nightly, weekly, monthly, quarterly to looking at real time data, get out of manual planning, everything where planners are touching every item, every channel, to looking at automated or autonomous planning so that we can elevate how our planners, our business analysts are engaging. Right? So, lots of great examples there for you to consider as you evolve, not just your supply chain planning process, but your sales and operations planning process.

Karin Bursa (21:26):

Now, some of the best presentations that I attended were case studies. These were delivered by practitioners.

So come back to me, if you’re multitasking! I really want you to hear about these couple of end-user presentations that stood out to me. The first one focused on growth. That’s right, Growth! This presentation was delivered by Diageo; Livia Kandiyoti Konak, who is the head of planning and logistics with Diageo. Livia delivered a really inspirational session focused on leveraging supply chain capabilities to fuel growth. I loved that Livia started with the goal of delighting customers! That’s right, delighting customers, a worthy goal that honestly has resulted in an impressive 20% single year growth rate. Let me say that again. The goal is delighting customers. Well, they must be delighted because the result has been an impressive 20% single year growth. That’s huge!

Karin Bursa (22:47):

If you’re not familiar with Diageo, I bet you’re familiar with many of their brands. Diageo is a global drinks business that ranked number 16 on the Gartner Top 25 Supply Chains for 2022. And it’s got iconic brands like Guinness, Johnny Walker, Gordon’s, and Smirnoff. Another measure of the success to date for Diageo is that it has now ranked first place for supply chain excellence and customer service in the UK. That’s right, first place. That’s a big jump.

Livia is leading a team that is achieving this rapid transformation, and they are in fact delivering what every supply chain professional wants. They are delivering better visibility, optimization, and autonomous planning. Diageo is deploying OMP’s Unison Planning platform. OMP is Diageo’s technology partner in this transformation initiative. So, today Diageo has the agility to anticipate and respond to demand and channel shifts, supply chain constraints to model those, to look at packaging transitions, to look at product and market segmentation all while delivering significant growth, and the Diageo customer is in fact delighted with the improved service levels. It’s also worth noting that Diageo is also committed to both grain and glass sustainability.

Karin Bursa (24:40):

If we go back to that list of what’s on the CEO’s agenda, we’re looking at examples here of growth. We’re looking at examples of sustainability. We’re looking at making better decisions, leveraging technology. And we are looking at automation, the ability to elevate and relieve some of that cognitive overload. So, I thought this particular case study really brought many of those messages to the forefront in a very tangible way for me, in a very, very tangible way.

Another great case study. So, come back to me because I want you to hear this. This is a very different company than Diageo. This was Border States Electric. So, Border States Electric, and it was about navigating the disruptions. They were impressive, very, very practical recommendations.

And so, the presenters were Tony Serati, who is the vice president of procurement with Border States Electric. So, Border States Electric is a leading electrical distributor, about $3 billion in revenue, and they have been working with GainSystems. Bill Benton, the co-founder of GainSystems, presented with him. Tony told us about what Border States Electric has been up to. They’ve been navigating all of these supply chain disruptions, and they are leveraging AI, artificial intelligence, to drive automation.

So, back to those CEO themes I mentioned – automation, better decision-making, and leveraging technology, this is another great example. A little bit about Border States, because it may not be a name you’re familiar with, they are one of the largest electrical distributors in North America. They’ve got a network of about 5000 suppliers, 100 locations, and approximately 300,000 SKUs.

Karin Bursa (26:51):

If you’re with me, supply chain movers or shakers, you are automatically thinking about the planning process in tapping 5000 suppliers, 100 locations and 300,000 SKUs. I did not get their number of customers, but I am sure that’s a big number as well. So, we’ve got to think about product, location, timing, optimization, and Tony shared that some of their lead times, you’re experiencing the same thing, I know, have exponentially extended. Instead of being able to look lead times in terms of days or weeks, they’re looking at weeks or months, and he even gave one example where lead time has extended from roughly four months for some items to nearly four years. That’s right. Imagine that. Now, that was an example or an outlier that he shared, but in the best-case scenario, extended lead times for many, many of the items that they like to provide and need to provide for their customers.

Karin Bursa (28:03):

Border States Electric has been augmenting their SAP ERP system with Gains, and they’re doing this to automate numerous planning processes and gain greater precision. Part of the goal is to free up planners to solver bigger problems, quicker response to disruptions of all types, pandemic and others, frequent price changes, supplier constraints, and a changing mix in customer demand. So, all of those themes go back to that CEO’s agenda, growth, leveraging technology, looking at elevating decision-making or accelerating decision-making and that customer service and how do I elevate what my talent is doing so that they can perform and make a bigger impact.

There were a few specific automation examples, and I want to share those with you. When Border States started, only 50% of their portfolio of 300,000 SKUs were forecasted. Today, that is +95% plus of all SKUs are forecasted with much greater accuracy than they were able to do before.

Karin Bursa (29:28):

They also talked in terms of multi-echelon planning and made this powerful statement. He said, “What took us days to do, now takes us minutes.” That’s right. What took us days, now takes us minutes. So, talk about freeing up your team members. Another example of acceleration was making a network change to better respond to a customer needs. Today, Border States has the agility to easily move stocking locations. They can move volume to specifically serve customers and do it as quickly and reliably as possible. So, Border States is also taking advantage of automated replenishment for a significant portion of its portfolio as well.

So, I think you can see why I was so excited about this. I liked the examples of automation, of acceleration, of the able to do more, right, covering that full product portfolio and elevating how their planning team engages and is now able to spend more time serving customers or working with suppliers versus just crunching numbers. A great case study that I think underscores many of the big themes that Gartner was challenging us with on where we should spend our time.

Karin Bursa (30:59):

Stay with me. I hope you hear the enthusiasm in my voice because it was really a great conference. There were great conversations in between sessions, opportunities to sit down with people you did not know at lunch and ask questions and see what was working in their environments as well. Now, many of these analysts delivered multiple sessions and one of three different sessions delivered by Gartner distinguished vice president, Noha Tohamy, focused on the consumer products supply chain. This was about innovating and adapting amidst this theme of accelerating change.

I thought that this was a really good session. It was packed with good data and relevant examples around top investments for consumer products companies to increase agility and resilience. A couple of those themes were supply chain segmentation. I mentioned this was also cited in the Diageo presentation. That was one of the things that Diageo is implementing is a segmentation strategy so that they can better support their never-out or their always available products for their customers.

Karin Bursa (32:26):

The second theme for Consumer Products is network design and a diversifying supply base. We’re not as focused today on the low-cost provider. We are looking for reliability and many times that means I’m going to have to go to multiple suppliers so that I can mitigate risks in my network and in the marketplace.

Number three is the redesign of products to reduce complexity. And then finally, gaining supply chain visibility. And you know, I say this all the time, visibility is on the top of every supply chain investment initiative. So, dig in and understand what visibility means to your company, to your culture, to your products, to the channels you serve, because I believe firmly there are opportunities to boost visibility across your supply chain operations. This session underscored that there is a dramatic shift in direct-to-consumer channels. I think we all agree with that. The pandemic just accelerated the transition. But what it means is that consumer products manufacturers now have to behave like retailers. They’re going direct-to-consumer. This requires a very different operating model, very different packaging, very different marketing. It’s a big shift. This transition is driving significant investments in areas like real time analytics to capture and analyze the data and execute in shorter, tighter cycles, respond to market opportunities faster.

Karin Bursa (34:20):

So speaking of consumer products and visibility, my friend, Rob Haddock, who is group director of planning and logistics at Coca-Cola, which was number 12 on the Gartner Top 25 Supply Chain list for 2022. Congratulations to the Coca-Cola team! Now, Rob is a well-known expert in the area of logistics and visibility, he was tapped to speak on a couple of different panels in a few different sessions. He was underscoring the critical nature of navigating these logistics disruptions, and responding to market changes with process improvements and technology in areas like network visibility, shipper collaboration, lane availability or lane sharing, yard visibility, even contactless pick-up and deliver, right, how can we reduce dwell times and improve the overall driver experience. Drivers continue to be a significant constraint, how do we improve their experience and get them able to execute faster or have greater visibility themselves.

Karin Bursa (35:46):

Rob has a great passion for connecting and educating and developing supply chain professionals. And every time I saw him in the hallway, he was surrounded by a group of people who were tapping his expertise or sharing what they’ve been able to achieve.

Now, a name that many of you that listen to TEKTOK regularly may be familiar with is Steve Barber. Steve Barber is with Transplace or now Transplace and Uber Freight, which have come together. Steve was a guest on TEKTOK just a few months ago. Now, Transplace and Uber Freight have more than $17 billion, that’s billion with a B, of freight that’s under management. And Steve talked about how they are transforming the traditional freight procurement process and introducing some new solutions for shippers so that they can really enable seamless procurement of lanes. They can look at things in the spot market or look at low volume planning, not just high volume planning. I think that we’ll hear more from Transplace and Uber Freight as they continue to bring these two businesses together.

Karin Bursa (37:10):

Stay with me. I’m trying to bring you the best of the best of some of the sessions at the Gartner 2022 Supply Chain Symposium, which took place this week and some just really good, really good market analysis, buyer behaviors, et cetera.

Another really hard-working Gartner analyst at this particular event was Amber Salley. Amber delivered three presentations and had dozens of one-on-one sessions with practitioners and solution providers. Amber Salley is the lead analyst on the Gartner Supply Chain Planning Magic Quadrant, which published just a few weeks ago. She delivered a session on the Magic Quadrant for Supply Chain Planning solutions. I’ve got to tell you, there were hundreds of people just captivated, standing around, again wall-to-wall, standing room only as Amber Salley went through some of the background information on how Gartner selected and evaluated 22 solution providers that qualified for the 2022 Gartner Supply Chain Planning Magic Quadrant. Now, I have been engaged with this particular magic quadrant for more than 25 years, and I still learn something every time. There is deep criteria in what gets evaluated around 15 critical capability. But there are also insights that come from Gartner’s engagement in the industry as well as a customer survey process that takes place. So, I learn something every time.

Karin Bursa (39:02):

And one of the interesting data points that Gartner shared is that they believe that the supply chain planning solutions market is currently valued at about $5.7 billion. That’s right, $5.7 billion. That’s demand, inventory, supply, production, replenishment, sales and operations planning, the analytics around those functions, valued at $5.7 billion. And the Supply Chain Planning marketplace is expected to grow at 13.6% through 2026. That is some healthy growth! And, I believe that that growth in part is inspired because back to the CEO’s agenda, how do we leverage technology, how do we accelerate decision-making, how do we evaluate hundreds of scenarios for our business and deliver for our customers, so continued investment in this area. So, buckle up supply chain movers and shakers, because change is coming!

Karin Bursa (40:12):

Now, as you might imagine, the networking at this event was fantastic. It started on Sunday and continued to the moment I got on the plane and returned to Atlanta late on Wednesday. And, I have a number of follow-up meetings that are planned as a result of the conference as well.

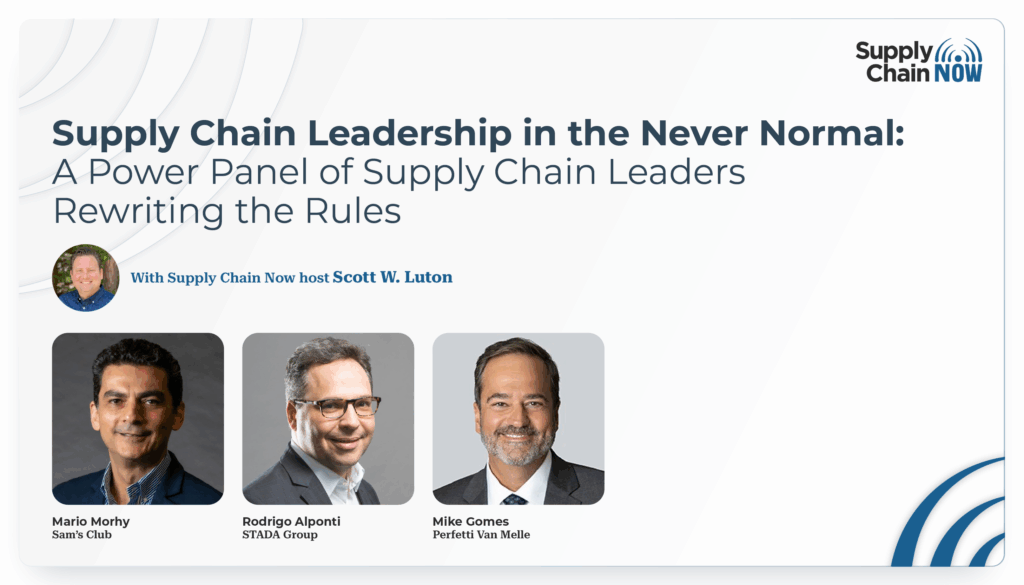

I am energized. I am excited. I am inspired. And I’ve got to tell you that no supply chain industry event would be complete without Supply Chain Now founder and host, Scott Luton, making an appearance. I think it surprised some people who had not met Scott in person before, but Scott is even more fantastic in real life than he is in the virtual world. He is so good at connecting people and engaging people, and that came through yet again in a live round table that he helped to moderate with Mark Holmes, who is with InterSystems. This roundtable was focused on How to Connect Data for Visibility and Actionable Insights. There we are again, visibility, harnessing data, leveraging technology, making better decisions faster.

Karin Bursa (41:39):

So in this very lively roundtable, which again was standing room only, underscored that future performance, goes beyond responding to supply chain disruptions. We’ve got to have the ability to consider things like inflation, rising costs, the Exodus of tribal knowledge, so this great resignation, right, where so much expertise is leaving our companies. We need to formalize or encapsulate some of that intelligence before it leaves our businesses and we need to harness data and not just our enterprise data, but new data sources. And we’ve got to transform data into actionable insights so that we can do more intelligent decision-making.

Karin Bursa (42:32):

I think you can see how that theme goes back to the CEO’s agenda as well, right? How do I fuel growth? How do I harness technology? How do I attract and retain my talent pool, my workforce? How do I make the investments that are really going to elevate the value proposition and look at these digital strategies? I could probably go on for another hour. But suffice it to say that face-to-face events are back and they are energizing! The exchange of ideas, the fresh inspiration, and some good old-fashion human connection are sure to fuel future innovation.

Karin Bursa (43:19):

If you were at the Gartner Symposium, please chime in with your highlights. Let me know what you connected with. And if you couldn’t be there this year, let me know what you found valuable from this recap. Bottom line supply chain movers and shakers, it is a great time to be in supply chain! That doesn’t mean it’s easy, but it is certainly worthwhile.

Karin Bursa (43:48):

Thank you for joining us on TEKTOK, where our goal is to help you eliminate the noise and focus in on the information and inspiration you need to transform your business and replace risky inventory with valuable insights.

We’ll see you next time on TEKTOK, powered by Supply Chain Now.