2026 Is the Year of No Excuses: Why Calmer Conditions Could Expose (and Reward) True Commercial Leadership

A Shift in the Narrative for 2026

In a recent conversation, Scott Luton spoke with Mark Gilham, Vice President & Head of Global Advisory at Enable, about what supply chain and commercial leaders should expect from the year ahead. While many annual outlooks attempt to forecast the next major disruption, Gilham offered a different lens: 2026 may become the “year of no excuses.”

After years defined by a global pandemic, inflationary shocks, geopolitical instability, supply shortages, and the rapid rise of AI, organizations have already endured extraordinary volatility. Businesses not only survived, but in many cases adapted and grew. According to Gilham, that reality weakens the argument that disruption alone explains underperformance.

Disruption is not disappearing, he cautioned, but leaders can only lean on it for so long.

Why a Calmer Year Raises the Bar

Gilham argued that if external conditions stabilize even slightly, the pressure on leadership actually increases. A less chaotic environment removes convenient explanations and shines a brighter light on internal shortcomings. Process gaps, misaligned incentives, and execution failures become harder to ignore when the world is not on fire.

Rather than waiting for certainty, Gilham believes leaders should act decisively. This does not mean radical transformation or reckless bets. It means tackling the known issues that have lingered on internal to-do lists for years. Organizations that use this period to proactively shape their markets tend to outperform those that hesitate. History, he noted, is rarely kind to companies that wait for competitors or uncertainty to make the first move.

From Optimization to Accountability

One of the biggest obstacles to sustained performance improvement is risk aversion. Gilham observed that many organizations struggle to move from optimization to accountability because changing something that is partially working feels dangerous. Over time, this mindset can quietly shift cultures toward avoiding mistakes rather than making progress.

The danger is subtle but profound. When employees fear consequences for every misstep, decision-making slows, risk-taking disappears, and innovation stalls. True optimization requires accepting that some initiatives will fail.

The distinction lies in preparation. Gilham emphasized the importance of calculated, informed risk: knowing the downside in advance, measuring impact properly, and understanding why outcomes occurred. This discipline applies equally to successes and failures. Without clear measurement, organizations risk scaling initiatives based on false assumptions.

This is where meaningful KPIs matter. Not vanity metrics, but measures that isolate what teams can genuinely influence. Accountability, in Gilham’s view, is not about blame. It is about clarity, learning, and continuous improvement.

The Hidden Cost of Misaligned Incentives

Drawing on experience across pricing, procurement, finance, and supply chain functions, Gilham highlighted incentive misalignment as a persistent source of value leakage. In wholesale distribution, buy-side and sell-side teams often operate with separate incentives, despite making interconnected commercial decisions. When alignment is missing, value quietly erodes.

In manufacturing and broader supply networks, the problem often extends beyond the enterprise. Trading agreements are frequently born from competitive negotiations where one side “wins” and the other “loses.” Gilham argued that this approach undermines long-term value creation.

The strongest relationships, he explained, begin with transparency around objectives and an honest discussion of overlap. Supply chains perform best when partners compete as integrated ecosystems, not as isolated entities. When incentives focus only on price or volume, organizations lose sight of what customers truly value: service, quality, and reliability. Delivering on those dimensions builds loyalty, reduces cost to serve, and unlocks reinvestable value.

Why Insight Still Fails to Become Action

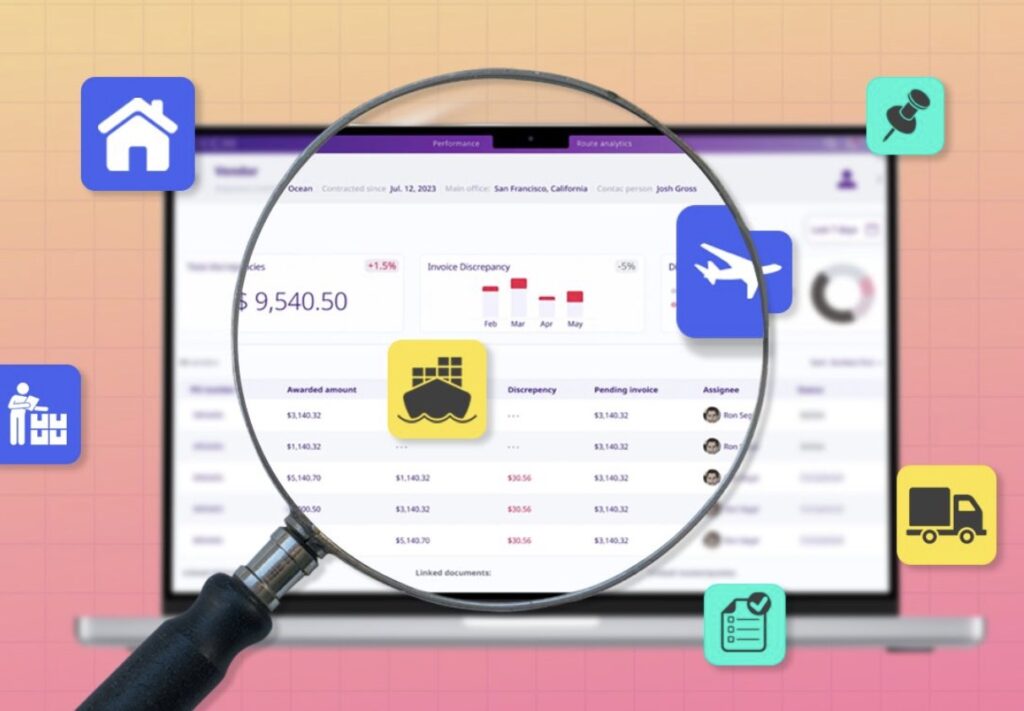

Despite better data and more sophisticated analytics, many organizations struggle to act on insight. Gilham pointed to dashboards as a common example. While modern dashboards look impressive, too many fail to drive decisions.

He distinguished between health-check dashboards, which indicate whether operations are functioning normally, and action-oriented dashboards, which should inform real-time commercial or operational choices. Too often, dashboards remain descriptive rather than directional.

The turning point comes when data experts and business leaders work closely together. When those skill sets combine, dashboards stop reporting history and start guiding performance.

One Practical Change for 2026

For leaders seeking measurable gains in 2026, Gilham offered a clear recommendation: make commercial programs truly measurable. Using rebates as an example, he noted that most organizations know exactly what these programs cost; but far fewer can quantify the value they deliver.

When rebates and discounts are viewed only as expenses, they are treated as giveaways rather than investments. Leaders serious about performance should insist on measuring both cost and return. When that shift occurs, decision-making improves, accountability increases, and commercial programs begin delivering the outcomes they were designed to achieve.

In a year with fewer excuses, discipline may be the ultimate differentiator.

Where to Learn More

Connect with Mark Gilham on LinkedIn and visit Enable’s website to explore their mission to enable trusted trading relationships to serve customers better together. We also invite you to check out a recent Supply Chain Now webinar, featuring Mark Gilham and Keith Wright, hosted by Scott W. Luton and Marty Parker, entitled: “2026 Procurement Priorities: What’s Changing (and What You Need to Do First)”: learn more here.

More Blogs

Navigating Hidden Freight Costs: Taking Control of Unexpected Charges