Supply chain professionals are regularly asked to save the day for their company… so does that make a career in supply chain an adventure?

In this episode, host Chris Barnes speaks with Megan Preston Meyer, a former insight analyst, about her illustrated book: FIFO Saves the Day, a Supply Jane Adventure. The purpose of the book is to teach supply chain principles – including stock rotation – to children.

The STEM movement aims to ensure that kids are exposed to the fields of science, technology, engineering, and math – and this book makes sure that supply chain is included as well.

More Podcast Episodes

data

Podcast

February 23, 2026

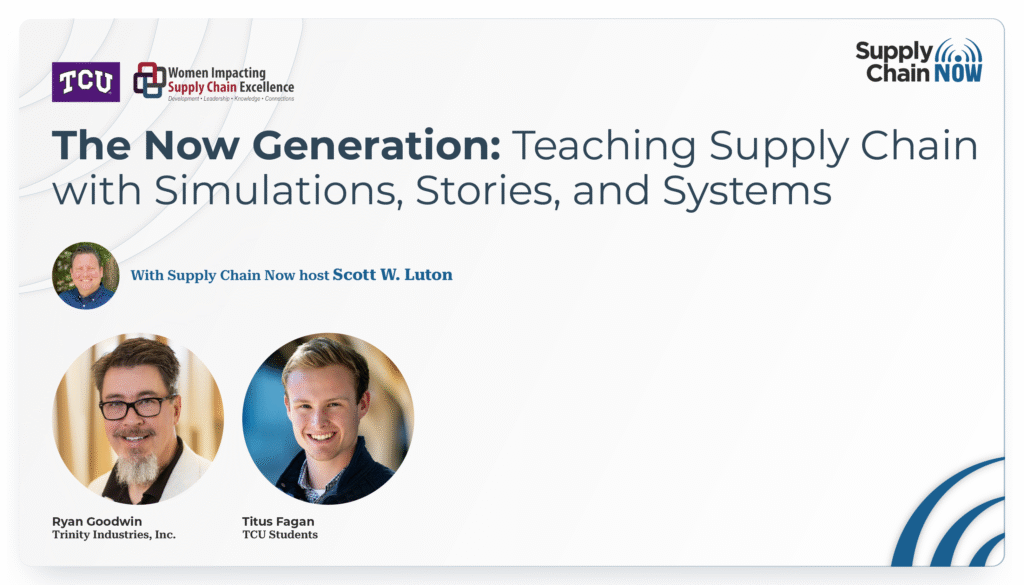

The Now Generation: Teaching Supply Chain with Simulations, Stories, and Systems

As supply chain technology accelerates, the ability to translate operational knowledge into scalable systems is becoming a defining advantage for both companies and early-career talent. In this episode of Supply Chain Now’s Now Generation series, Scott W. Luton sits down with Ryan Goodwin, Sr. Director of Supply Chain Technology & Innovation at Trinity Industries and an adjunct professor at Texas Christian University, alongside Titus Fagan, TCU Student Body Vice President and a third-year accounting major with a minor in energy business. Ryan shares how his team is integrating planning, MRP, and financial data into platforms that enable faster automation and application-building, often with the help of AI and “vibe coding,” where non-traditional builders can create real tools without a formal software background. Titus brings the student lens, explaining why practitioner-led teaching changes the classroom experience, how simulation-based learning builds cross-functional thinking, and why early responsibility and collaboration are top priorities when evaluating future employers. Together, they explore how AI can lower barriers to entry, accelerate skill development, and reduce manual work while also raising bigger questions about infrastructure, power demand, and the bottlenecks that can slow even the most innovative systems. From freight reporting automation to energy transmission constraints, this…

supply chain

Podcast

February 18, 2026

Building Resilient, Innovative Supply Chains Across Africa

Supply chains are recalibrating, and the Middle East and Africa are investing aggressively to meet the moment. In this episode of Supply Chain Now, Scott W. Luton and special guest co-host Yaseen Ahmid welcome Toby Maier, CEO for Middle East and Africa at DHL Global Forwarding, for a wide-ranging conversation on what is changing trade and logistics across the region. Toby breaks down how recent tariffs are redirecting export flows into the Middle East and Africa, why GCC countries are racing to build world-class logistics hubs, and how production is shifting from Turkey toward markets like Egypt and Morocco. They also explore what it will take to build stronger, more reliable supply chains across Africa, from investment in life sciences and healthcare infrastructure to modernized regulation that reduces delays at customs. Toby shares how DHL’s publicly announced $300 million investment through 2030 prioritizes end-to-end capability that helps medicines, vaccines, and other critical products reach communities across a fast-growing population. The conversation also tackles the practical realities of energy access, data centers, and the cost to deliver goods, plus how sustainability efforts like electrified fleets and sustainable aviation fuel can support performance and emissions goals at the same time. This…