WEBINAR: 5 Reasons Network Design Is Essential to Supply Chain Resiliency

Do you have the ability to model the cost, service, and risk implications of potential supply chain decisions? Here’s how better supply chain network design benefits your business and customers—and how to get started today.

If your organization has a physical supply chain, supply chain network design is a critical capability to create digital models of your current and future supply chain to test the impact and performance of multiple alternatives—before you invest a dime. Join C.H. Robinson and Optilogic in a practical discussion on how leading companies are taking a balanced approach to optimizing across multiple criteria such as cost, service, risk, and carbon emissions when developing supply chain strategy.

More Webinars

data

Webinar

February 8, 2022

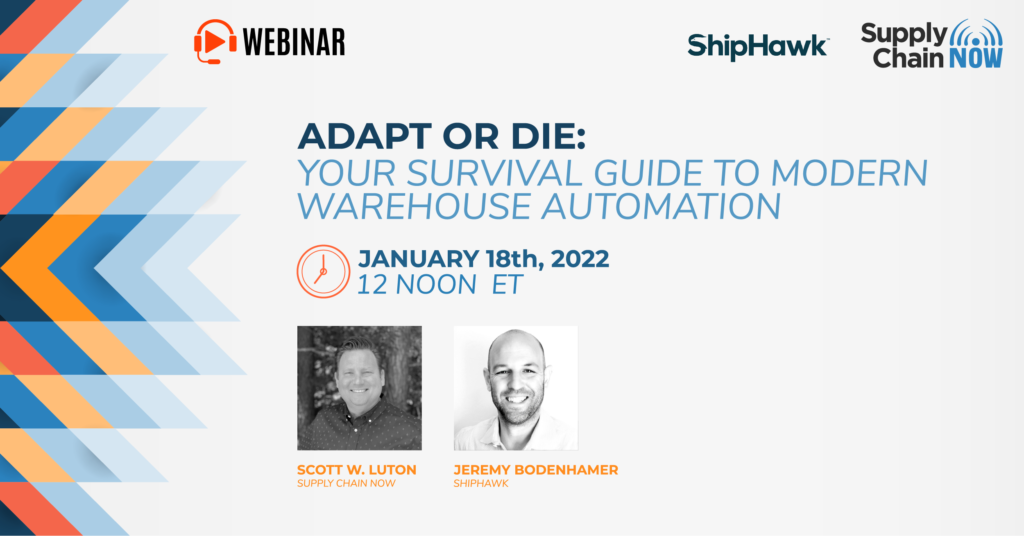

Adapt or Die: Your Survival Guide to Modern Warehouse Automation

If you sell physical products, warehousing and shipping costs can make or break your business. But most companies treat order fulfillment as an afterthought, running toward a future in which they won’t be able to compete with marketplace giants. Scott Luton with Supply Chain Now will sit down with Jeremy Bodenhamer, CEO of ShipHawk, the leading provider of advanced fulfillment software with expert guidance to help businesses scale. They’ll discuss the need to adapt to today’s ever-changing supply chain or face extinction, including case studies in which one wrong move in something as simple as packaging can send a company into the red. But there is a better way. By embracing end-to-end automation, companies can ensure that every item is warehoused effectively and shipped quickly, in the best package, at the best rate that meets customer expectations, restoring critical savings to your bottom line. And you don’t have to be Amazon to do this.

agility

Webinar

December 15, 2022

3 Ways to Future-Proof your Shipping for 2023 and Beyond

Parcel shipping has been turbulent, and changes aren’t done. Logistics Intelligence software-provider Sifted will share how parcel shippers can use their shipping data to assess the health of their operations, set achievable goals, and execute on them. Shippers that do this can build more profitable and resilient parcel operations for 2023 and beyond.