Accelerating Decision Velocity: Why the Future Belongs to Faster, Smarter Supply Chain Decisions

Special Guest Blog Post written by Karin Bursa, Supply Chain Industry Advisor and Supply Chain Now Host

Here is a diagnostic question I use with supply chain leaders: when disruption hits, do your teams spend most of their time debating the data, debating the scenarios, debating the plan, or debating the decision? Or all of the above?

Seriously though, in 2026, that distinction matters. Network shifts driven by tariffs, geopolitics, cost pressure, and sustainability are accelerating. Gartner’s 2025 U.S. Trade and Immigration Policy Survey indicate 77% of respondents selected network changes among their top actions in response to tariff impacts. [2] If the physical network is moving, the digital planning platform must move even faster.

The environment is forcing decisions to be made faster, more frequently, and with more variables than ever before. Gartner says supply chain decisions are becoming 71% more complex, happening 52% more frequently, and need to be made 57% faster. That triple constraint cannot be accomplished with cadence-based batch planning cycles as a default operating model.

This is why I am focused on a single, practical outcome for supply chain teams: accelerating decision velocity. The ability to move from data to insights to actions faster and with greater confidence, repeatedly and at scale.

And to be clear, decision velocity is not “working harder.” It is deciding better – with the right speed, clarity, alignment, automation while reducing overall business risk through transparency, decision rights, and auditability. It is no surprise that CEOs are simultaneously prioritizing growth, cost reduction, and better decision-making. Today, the success of an organization is nothing but the sum of all its decisions.

Why decision velocity is the KPI that matters now

Most supply chain KPIs were designed for stability and relied on history: forecast accuracy, plan adherence, utilization, inventory turns, and customer service. They still matter, but they look backwards, at past performance.

Decision velocity is forward-looking and operationally actionable. It shows up in measurable ways:

- Signal speed: How fast you detect change (tariffs, demand volatility, shortages, disruptions).

- Decision clarity: How fast you isolate root cause and evaluate options.

- Execution latency: How fast you turn a decision into an outcome in planning and execution.

If you are feeling pressure from the boardroom, you are not alone. US trade policy changes are already driving major supply chain strategy shifts. The implication is straightforward: the supply chain cannot just react faster—it must plan continuously with greater precision. Continuous planning doesn’t just increase speed, it increases decision quality over time, because plans are continuously refined as the latest market and enterprise signals flow into the model.

If you cannot generate and compare multiple end-to-end scenarios quickly, decision velocity collapses precisely when leadership needs it most.

Five moves to accelerate decision velocity

To accelerate decision velocity five capabilities must come together and reinforce one another to increase speed, quality, and confidence simultaneously.

1) Improve visibility (the right data in the right context)

Today, visibility is table stakes. How quickly you take action from the visibility is the differentiator. Harmonize signals across demand, supply, inventory, capacity, logistics, and commercial constraints—and present them in a way that supports trade-offs (cost, service, cash, and risk) in minutes, not meetings.

When visibility is weak, teams burn cycles debating the numbers or operating in disconnected spreadsheets instead of debating the decisions and implementing the plan with confidence.

Visibility improves dramatically when you augment internal enterprise with external market signals to reduce latency, drive precision and build trust in the plan.

2) Align plans end-to-end (so decisions do not break downstream)

End-to-end alignment is where planning becomes a performance engine. It closes the gap between strategic intent, operational feasibility, and execution reality. The goal is a shared plan that can be viewed through different lenses (finance, customer, plant, DC, distribution, market) and across different time horizons such as days, weeks, months, years. End-to-end alignment also clarifies decision rights for ownership, threshold performance ranges, and trade-offs. So, speed doesn’t create downstream rework.

3) Move from batch planning to continuous planning.

Tariffs make this real. If 77% of leaders are contemplating network changes, the question isn’t whether you can design a new network—it’s whether you can simulate multiple scenarios quickly using a supply chain digital twin to understand the service, cost, and risk implications before the next escalation.

Decision velocity accelerates as trust grows – trust in the process, trust in the model, and trust in the operating process around it. When demand, supply, capacity, and scheduling run in a single, responsive, synchronized platform, supply chain teams spend less time reconciling functional plans and more time acting with clear traceability and confidence. No more latency. No more manual reconciliation. Confident clarity to act with agility as you address demand volatility, supplier challenges, or production changes in minutes instead of days.

4) Accelerate the shift from data-to-insights-to-actions.

Think of AI across three modes: Analytic AI (optimization and machine learning) to evaluate trade-offs and optimize at scale; GenAI to accelerate understanding, explanation, and decision documentation; and Agentic AI to monitor events and trigger workflows within defined guardrails. The point isn’t automation for its own sake, it is consistent, explainable decisions at the speed the business now demands.

The workforce reality is also changing. AI is rapidly becoming the baseline expectation for how work gets done. As Harvard Business School professor Karim Lakhani put it: “AI won’t replace humans, but humans with AI will replace humans without AI.”

Zero100 reports that 93% of senior supply chain leaders expect planning workflows to change, with some workflows disappearing altogether. This is not “AI replacing planners.” It is planners being elevated—from data manipulation to decision orchestration. OMP is moving in this direction by combining advanced engines with new analytic, generative, and agentic AI capabilities designed to increase decision velocity with supply chain context, governance, and decision traceability.

5) Engage people in the decision velocity design.

Adoption is a critical requirement for sustainable success. You cannot make faster decisions if teams do not trust the solution, do not understand the logic, or aren’t incented to use it. Treat skills development, change management, and “AI mastery” as core workstreams, not afterthoughts.

When teams trust the model and understand the “why” behind recommendations, speed becomes sustainable because decisions don’t have to be reevaluated.

Kraft Heinz: a practical model for decision velocity

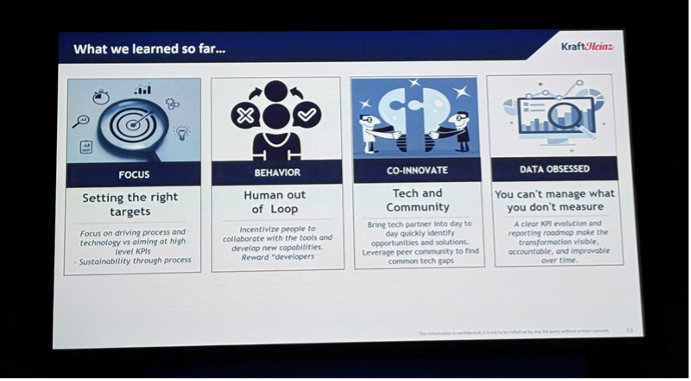

At the OMP REAL Conference and later at the Gartner Supply Chain Planning Summit, Kraft Heinz made the benefits of decision velocity tangible. Kraft Heinz shared what it looks like when a global organization pairs disciplined operating rhythms with and OMP-enabled planning platform outlining a multi-year journey toward touchless manufacturing planning and a smarter, more sustainable value chain. [1]

Figure 1. “What we learned so far…” — Kraft Heinz, OMP REAL Customer Conference.

Their “What we learned so far” insights offer a practical checklist for any organization aiming for autonomous, always-on planning:

- Focus — Setting the right targets

If targets are wrong, the solver can be perfect and still produce the wrong outcome. Take the time to define what “good” looks like and leverage the planning model to establish a repeatable process and reliable outcomes. - Behavior — Human out of the loop

This is not about removing people. It is about removing repetitive, low-value touches so planners can focus on exceptions, trade-offs, and targeted improvements that deliver outsized impact. - Co-innovate — Tech and community

The fastest path to decision velocity is rarely isolated brilliance. It is sharing learning, proven patterns, and a community that collaborates to close gaps or harness new opportunities. - Data obsessed — You can’t manage what you don’t measure

Decision velocity improves when teams instrument the process, determine where latency lives and enact steps to change for speed, accuracy, and outcomes.

Kraft Heinz also reinforced something I see repeatedly: people drive sustainable improvement. The real unlock is moving teams from “users” to “masters” which requires an investment in upskilling team members, so planners stop fighting the solver and start improving the model for automation. This mindset also underscores that AI-adoption and process automation are being done to amplify team impact.

Kraft Heinz’s results are impressive—and the platform choice is an important part of the story. Kraft Heinz is using OMP as its decision-centric planning backbone, pairing advanced AI-empowered planning engines with disciplined operating processes that scale across the global enterprise. Kraft Heinz should be proud of the progress to date: 250+ live sites and DCs, 300+ planners, 7,000+ SKUs planned, and a $90 million inventory reduction year-over-year. That scale matters—it creates the foundation for continuous improvement, faster scenario response, and more rapid decision velocity.

The need for speed

Decision velocity is becoming a defining advantage in supply chain performance. It is achieved through AI-enabled decision-centric planning spanning visibility, end-to-end alignment, and acceleration from data to insights to actions.

If your supply chain team is being asked to quickly respond to tariffs, volatility, and cost pressure while still delivering growth and service, the path forward is not more human heroics. It is accelerating your decision velocity through AI-driven decision-centric planning.

The goal is not speed at any cost, it’s faster decisions with greater confidence, because assumptions are explicit, scenarios are comparable, and outcomes are measurable. At the end of the day, the success of your organization really is the sum of all its decisions.

Sources

- [1] OMP. “Kraft Heinz showcases smarter, more sustainable value chain at Gartner Supply Chain Planning Summit.” 2025. https://omp.com/news-events/news/2025/kraft-heinz-showcases-smarter-more-sustainable-value-chain-at-gartner-planning-summit

- [2] EFCOG. “Supply Chain Task Team – Information Sharing: Tariff Transmittal” (includes slides citing the 2025 Gartner U.S. Trade and Immigration Policy Impact on Supply Chain Survey). 2025. https://efcog.org/wp-content/uploads/2025/10/EFCOG-PowerPoint_Information_Sharing_Tariff_Transmittal-2025-9.pdf

More Blogs

Five Questions I Wished People Asked Me About Public Sector Supply Chains