WEBINAR: Beyond One Number Forecasts: Why a Probabilistic Approach is Better to Manage Uncertainty

Is there still a place for demand forecasting in today’s world of constant volatility? Anticipating uncertainty with demand forecasting is a critical driver of inventory health and delivering stand-out customer experiences.

Join us for a conversation on:

– Probabilistic forecasting: a primer

– Three ways probabilistic forecasts outperform single-point demand forecasts

– The value probabilistic forecasts provide to make better supply chain decisions, optimize inventory and maximize working capital and profitability

More Webinars

supply chain

Webinar

June 20, 2024

How to Accelerate AI-Driven Decision Intelligence with Smart Data Fabric

Increasing operational costs, labor shortages, and geopolitical tensions are keenly felt by supply chain organizations and highlight the importance of fast, informed decision-making. Join this exciting webinar to learn how a smart data fabric can be used to unify data across disparate sources and accelerate AI-driven decision intelligence. We’ll delve into real-world use cases showing how this approach can be used to leverage real-time predictive and prescriptive analytics, as well as generative AI, to optimize your supply chain operations. Register to learn about smart data fabric and how this approach can help organizations attain an agile supply chain with integrated decision intelligence. Key Takeaways: – InterSystems Smart Data Fabric for consistent unified data – Supercharged problem-solving with Data Fabrics and Generative AI – Accelerated business value to LOB with decision intelligence

supply chain

Webinar

August 15, 2022

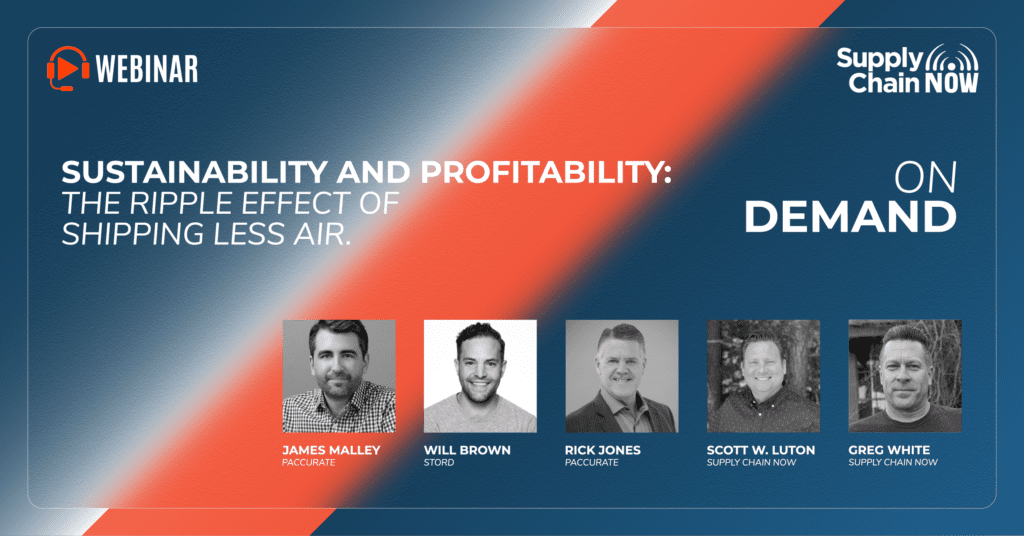

Sustainability and Profitability: The Ripple Effect of Shipping Less Air

Parcel shipping is at the heart of e-commerce operations. Despite this, many shippers don’t realize that small changes to their cartons or packing can yield dramatic cost savings and SCOPE-3 emissions reduction. In this webinar, we’ll explore the compounding effect of using the right size cartons, and optimizing how they’re packed: 1. How costs and SCOPE-3 emissions in fulfillment are linked 2. Why packaging matters 3. How cartons affect carrier capacity 4. Cartonization technology that can help