Episode Summary

“Sometimes you have to just look at the numbers and let them lead the way. Nothing in procurement or supply chain goes better when we make decisions emotionally.”

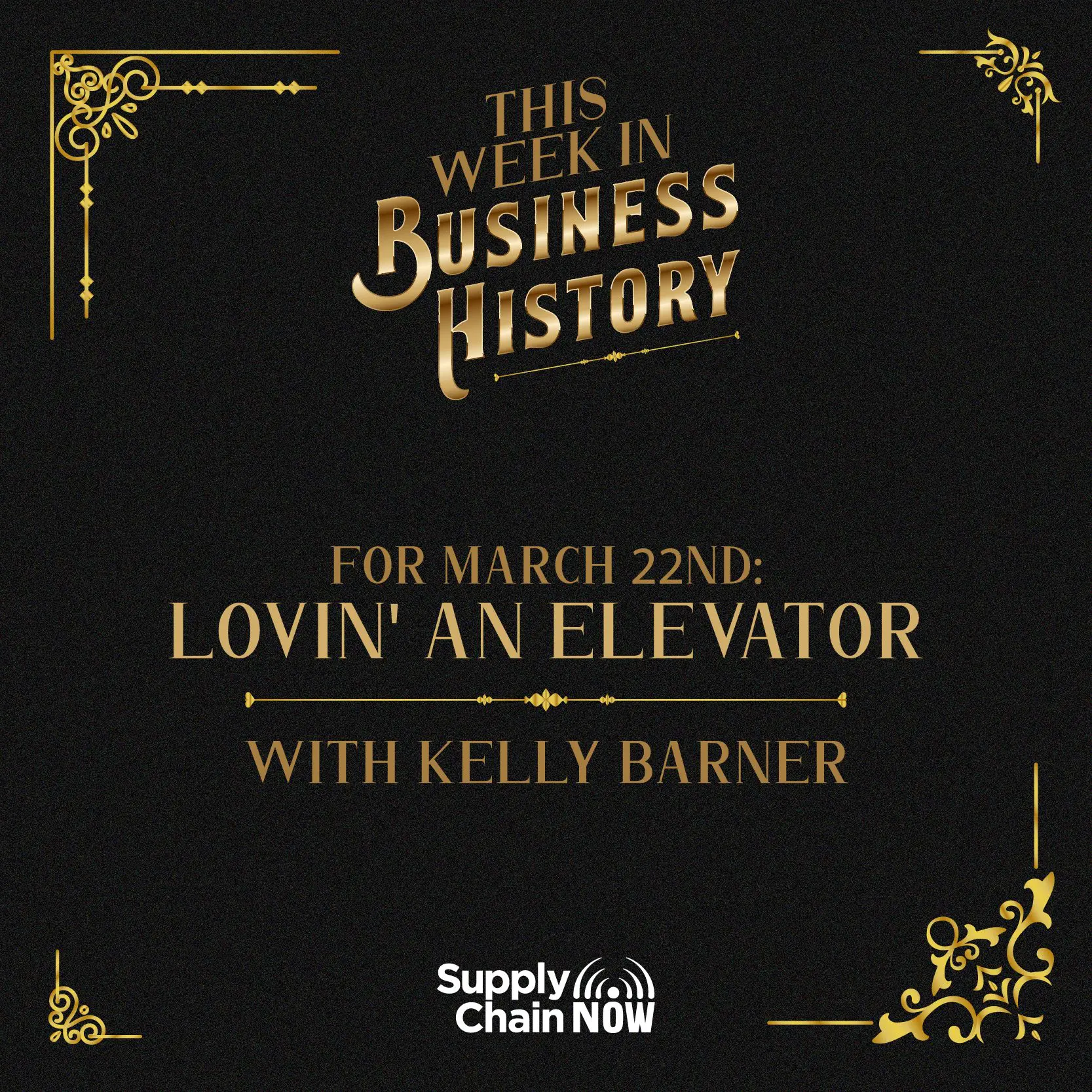

Kelly Barner, Owner & Managing Director of Buyers Meeting Point

No one grows up wanting to be in procurement. That said, the attitude you have and the passion you bring once you end up there can be the difference between a company that fully optimizes its supply partners and one that just meets basic needs.

Kelly Barner is the Owner and Managing Director of Buyers Meeting Point, and – like most of her colleagues – she didn’t set out to end up in procurement. Almost 20 years after being ‘assigned’ to procurement, she has become one of the leading writers and influencers in the global procurement community.

In this conversation, Kelly chats with Supply Chain Now Co-hosts Greg White and Scott Luton about:

· Her major takeaways from the recent Mastermind LIVE virtual event run by Art of Procurement, where Kelly is the General Manager

· What she’s hearing, seeing, and reading about the reshoring trend that everyone was sure was going to remake manufacturing supply chains in the aftermath of the COVID-19 pandemic

· How we need to factor a variable planning horizon into our strategies and tactics for the foreseeable future

Episode Transcript

Intro/Outro (00:05):

It’s time for supply chain. Now broadcasting live from the supply chain capital of the country. Atlanta, Georgia heard around the world. Supply chain. Now spotlights the best in all things. Supply chain, the people, the technologies, the best practices and the critical issues of the day. And now here are your hosts.

Scott Luton (00:41):

Hey, good afternoon, Scott Luton and Greg white with you here on supply chain. Now welcome to today’s live stream, Greg. Good afternoon. How are you doing? I’m doing quite well. How are you? I’ve been better. I’ve been better. Uh, sorry. It’s hard for me to internalize these things. You know, I am, I’m great at compartmentalizing. Like I’m not ruminating on the fact that the chiefs got stumped by the Raiders last Sunday, not at all. Um, so I empathize with the whole brave situation last from the past, wasn’t it? It, it really was. And it went from, you know, top of the mountain to, you know, the last, uh, 10 innings have been tough, but you know what? It’s a new day. The Braves are still up two games, a one, and we’ll just see how it plays out. So Ben, as clay said, he’s Clayton Kershaw has a history of in the playoffs.

Scott Luton (01:41):

So from your lips to God’s ears, for sure. So we’ll see what happens, but Hey, it’s baseball. There’s a lot bigger topics out there and we’re going to be fine. Just whatever takes place. The Dodgers are a very talented team. So let’s see where we go from here. In the meantime, we’ve got an outstanding guest here today. Uh, so to our audience, we’ve got Kelly Barner with buyers meeting 0.1 of our longtime friends of the show, one of the absolute business gurus, but in particular procurement gurus that you can learn from. I learned something new every single time. And Greg, we’ve got some neat stuff. We’re gonna be talking about that. They were actually showed her stuff yesterday. Didn’t she? I mean, you know, we got to see what her expertise can lend to an open conversation. So I’m so glad I am too. So it’s real funny. I’ve just a couple days ago, she was in the, in the comments, uh, to your point talking GPS and now she’s with us here and she’s our featured guests. The world is such a small place. Alright, let’s say hello to a few folks before we share a couple of announcements. So friends, Francoise is tuned in via Norcross, Georgia right here in the local Metro Atlanta area. Great to have you here. So Francois Joseph Maretta law listener today, it’s been a while. Doesn’t it? It’s good to have him back.

Scott Luton (03:01):

We know Joseph does a lot of keynotes. Yeah. He’s on the board for a supply chain group up in the Northeast. So that needs a pretty busy dude these days,

Greg White (03:09):

Everybody works for a living, so right. That’s all right. We’re glad to have you here. We right when you were away

Scott Luton (03:17):

T squared via YouTube. Great. And had you back, uh, he’s looking forward to today.

Scott Luton (03:22):

Oh, look how it puts this in other regulars

Scott Luton (03:25):

To the supply chain management nourishment.

Scott Luton (03:27):

That’s about the com. I love it. That, yeah. I love it.

Scott Luton (03:31):

Hassan and Tom Raftery, Tom rafters with us. We’ve got him coming up on a sustainability livestream in November.

Scott Luton (03:39):

Yeah. Hello to you from no winter for Tom, right?

Scott Luton (03:44):

That’s right. So that loads everybody, uh, for afraid of, and Mike avers is back with us. A great to have everybody. All right. So let’s do this. I want to cover, uh, Greg let’s tackle just a couple of quick events, right? We’re going to kind of, this is going to be, um, bizarro Thursday, maybe move things around a bit. So want to make sure folks are aware of a couple of these events that we’re, um, a part of, but also great resources as we continue to get better and better in these challenging times, uh, AME association for manufacturing excellence, uh, has got their upcoming virtual annual event coming up AME Toronto, 2020, as Greg likes to say, what might have some nice pictures of Toronto in the background. That’s what we’re reading here. Um, but Greg and I are hosting this panel as part of the overall programming and the panel not only features a CEO of AME Kim Humphrey, but we’re going to be tackling lean. We’re going to attack and reassuring and nearshoring and kind of industry 4.0. So, um, you can learn more about this event and we’ve got the link in the show notes, one click. That’s what we’re after. So y’all check out the AME Toronto 2020 event. Greg. One last word about that event.

Greg White (04:56):

Lean will definitely be a topic I’m telling you. Everybody’s leaning on lien, leaning in on lien or given lien a lien path. So we look it’s, it’s something we need to talk about and we need to sort of root out there. There have been a lot of, um, gross generalizations made about a lot of topics. And I bet we’re going to talk about some of those today with Kelly. So we are on this AME thing and learn what you can from manufacturing. Yup.

Scott Luton (05:27):

We’ll put, Hey really quick. Before we get to the next one. Uh, we got a comment that we never get ever get, especially with my inability to put, uh, uh, vowels and constant together. Francoists says thanks for having me and for getting my name right. Francoise tip of the hat view.

Scott Luton (05:42):

Thanks for the feedback because

Scott Luton (05:44):

I struggled to pronounce my kids’ name sometimes.

Greg White (05:46):

Well, notice the principle that we didn’t tackle your last name. So, um, we’d love any phonetic spelling that you can offer there. That’s right. One step at a time we try to honor people’s that’s right, right. So, uh, hello, Thomas, uh, Thomas dent. Great to have you here with us, Danny Benevides is here with us. Great to have you, Danny looks, looks like both of those folks are via LinkedIn, so great to have you here. Number five is back our resident comedian and, uh, our resident Mark Twain of supply chain humor. So, so, um, and also near Fahd has an initiative out there that we may be talking about shortly and maybe speaking of lean, right? Yeah. That’s what we’re all after. All right. One more. Yeah. That too. Oh, so it’s even secret from you. That’s right. Let’s do at some point. So let’s talk about this real quick, uh, stand up and sound off.

Scott Luton (06:46):

So we’ve got this, uh, international forum coming up, be a webinar, uh, the end of the month here. And we’re really, it’s gonna be focused on, um, a very interactive conversation on how Elba and Anya are driving equity, equity initiatives within very large organizations. And they’re going to share some of their best practices and experience. And we’re going to hear from the audience the best part about these, these standup and sound off programs. Greg is you hear from the panel, but our audience gets equal time to weigh in and not just ask questions, but share their, their experiences, right? Yeah, no doubt. And that’s what we want. Right. We want people that make this a comfortable conversation. As we talked about Corrine, and I talked about yesterday, the conversations that cause these conversations to be necessary and uncomfortable are the conversations that should be uncomfortable.

Greg White (07:41):

Yeah. I think we’re going to talk a little bit about that, but look, I think that the spirit in which everyone kind of approaches these, it feels, I think it feels a little bit difficult for people going in, but man, when you see how much consensus and how much people care for one another, when you have one of these conversations, it’s so uplifting. Yeah. It does give you great faith in humankind. Absolutely. And you know, you seek first to understand and, and UN under uncover, uh, various walks of life from their POV and their perspective. And, and you know, you never know, you always benefit from those conversations. So, um, we’ll put there Greg, and to our audience, you can check that out and sign up for free that the link is in the show notes. Again, one clicks what we’re after. Uh, so y’all check that out. I want to share a couple of quick comments before we bring on the one and only Kelly Barner. Uh, Gary Smith is with us. Uh, great to have you here, Gary. Appreciate all the, the listenership. Uh, I think Gary and I are both big history fans and we’ve been exchanging a few messages on this week in business history. Jaman our resident logistics and transportation guru, man logistics and beyond one of our new series

Scott Luton (08:56):

Here led by the one and only Jamie and great to have you here. So we’re talking lean already, right. And, uh, Francoise already, he brings a goodness. So that sounds nourishment that, uh, T-square was talking about liens important, but it would be interesting to see how that plays into this just in time manufacturing and how unexpected disruptions like COVID may change the point of view own just in time supply chain. I agree with you, uh, as, as Greg and I both have talked a thousand times and they, everyone knows, uh, the pandemic has uncovered a wide variety of, of, uh, gaps and challenges. So it will be interesting to see how 20, 20 shapes, uh, those views on longstanding best practices. Yeah, no doubt. Alright. Let’s uh, Patrick Kelly’s with, it’s great to have you Patrick, the produce industry podcast. Um, and I think we had one with a person to acknowledge Greg. Oh, I saw Nairobi also earlier. Did you mention her, but I don’t think I did go. He joined us after some time away, so that’s good. Good to have her here. All right. Absolutely. So with no further ado, we want to welcome in our one of our best friends and industry. Uh, the procurement guru, no doubt Kelly Barner owner and managing director with buyers meeting point.

Scott Luton (10:19):

Hey, good afternoon, Kelly, how are you doing?

Kelly Barner (10:21):

I’m doing good. How are you guys

Greg White (10:24):

Doing much better now?

Kelly Barner (10:27):

Which one?

Scott Luton (10:30):

Yeah, so Greg, um, you know, I bet it’s been two or three years since I first sat down with Kelly and featured her in a webinar, uh, with a webinar series that we were leading way back when and incredible first impression I learned so much that proverbial 17 pages of notes, and I’ve been very fortunate and our team here has been fortunate to do a lot more with her in the, in the year since, uh, great to have her here with us on live stream and, and Kelly for our audience has benefit that all three of them that haven’t checked out your content. And some of the things you’re up to, uh, tell, tell us about yourself.

Kelly Barner (11:04):

Sure. So I’m a Boston girl. I’ll make a special effort for you guys to speak slowly and put ours on the end of my words. Exactly. I’ll sprinkle in some wickeds here and there. Um, I ended up in procurement by mistake. Um, my original plan was to major in English literature before 17 hundreds. So I was Shakespeare girl and really took a seriously wrong turn someplace. Um, but absolutely love procurement. Got my start in the industry in grocery retail. Um, so all the ins and outs of not for resale hired services, grocery pest control, there’s some really awesome stories. There might be appropriate for Halloween, so a few weeks. Um, but no, I’m, I’m thrilled to be here with you guys today, glad to on the live stream.

Scott Luton (11:54):

Awesome. Awesome. And you know, Kyla, doesn’t talk much about herself. She’s a published author of some outstanding selling publications are to procurement has a great podcast by the way, then I think they just surpassed you also just surpassed 500,000 listens to Kelly.

Kelly Barner (12:10):

I find a thousand lessons,

Scott Luton (12:12):

Credible, an, uh, we’re going to talk about a great event. I know y’all have gotten a ton of positive feedback around mastermind live 2020, where you’re going to share some key takeaways. So, but all in all in due time, right. I’ll do Tom to talk tackle. Yeah. So for starters, Kelly, uh, you know, Greg, we had a great conversation with Omnia partners, uh, Tuesday, where really you and I both have been learning a lot more about, uh, GPS, right? I, for one, I was completely ignorant, you know, that that’s not something I dealt with during my time sitting in the chair as a practitioner. Um, I had a great lab strain, the audience weighed in and a lot of different things. Um, I know we want to kind of pick Kelly’s brain who we were, we had, uh, we were fortunate to have for part of that time. And what were a couple of key takeaways from that conversation Kelly that you walked away with?

Kelly Barner (13:00):

So I think the big thing for me and anybody with us that doesn’t happen to be super familiar with the GPO. Um, they basically work in industries where you can relatively standardize your specs across some common products. So, you know, the classic example kind of is office supplies. You know, if I can go to a GPO and throw my volume in with some contracts and some pricing, they already have negotiated, right? Almost no effort on my end, great savings. There’s no issue. It’s a standard spec. So they’re very popular in, uh, healthcare and they’re very popular and higher education, but it’s something that a lot of procurement teams, I happen to think we’re kind of overlooking right now. We’re under a lot of pressure as everyone else’s to bring, spend under management, what should do it without losing any of the progress we’ve made around repositioning procurement as more strategic?

Kelly Barner (13:58):

So to me, a GPO is a fantastic way to take care of some of that spend where you’re probably looking at like a standard three year contract. Nobody really has dedicated category experts in house anymore that cover all their spends. So it doesn’t negotiate at something in the last three years. It’s probably really different now why gain that expertise? Just go to the GPO. And it’s one of those things where if you have the right pairing, applying a GPO is no different than selecting a specific negotiation strategy. A lot of procurement people need to be looking at, as we get into the fourth quarter and start thinking about 20, 21, how are we going to handle so much unknown with so little lead time? Uh, I do think it’s one of those areas that we need to be truthfully reconsidering in our portfolio tools because we have a lot of different approaches we can use.

Scott Luton (14:54):

Hmm. Well put, uh, Greg, well put, um, so yeah, that’s just, that’s a really, um, enlightening perspective because I think about management in general, right? Those things that can be manually managed by automation or a group or something like that they should, and, and that leaves your team more time to work on exceptional circumstances or specialized circumstances, which you just described there, you’ll have to worry about how good a deal I’ve got with my pencil or, or, or parking lot cleaning or healthcare provider. Um, then they can spend more time on this minute spec that makes the complete difference in our product, in the marketplace or, or something like that. Right.

Kelly Barner (15:48):

It’s still, it’s still not a set it and forget it kind of deal. It forms one strategic relationship that manages a lot of different products, services categories of spend. So someone in house still has to manage the relationship with the GPO, but it’s really an effective way to bring, spend under management at scale very quickly and not have any loss.

Scott Luton (16:09):

Yeah. I also liked your remark about, uh, having experts that really know it, that come from those different parts of industry. And you’ve got that customized, um, uh, the, the folks that know the experts right on whatever you’re trying to negotiate. That’s a big value that helps organizations move faster. Okay. So let’s keep driving up, Greg. I know we want to talk about mastermind lab 2020. Let me make just a few shout outs to the audience before we go there. Um, Hey, T squared, I get your, uh, I love your comment about reverse logistics. It does need to be talked about more. We have to continue our series on reverse logistics, uh, stay tuned for a lot more to come as we move into, uh, a brand new era for reverse logistics, hopefully we post pandemic, right. Um, Jaman, uh, agrees with, uh, Francois’s point about the, uh, evolution of JIT supply chain and, and just in time manufacturing, that would be interesting to watch Mike Eva says, Hey, COVID raised safety stock levels across the board that, uh, lean folks don’t, don’t like hearing that, right. Uh, let’s see. You want to say hello to David, want to say hello to, uh, AA from the air capital of world Wichita, Kansas, right. Greg proverbial area and, uh, Lisa Lisa Kinski. Great. Great to have you here. Thanks so much for tuning in via LinkedIn live, uh, one final point. So Jaman, uh, who would we, we set a low too earlier, uh, first off he says you were great Kelly and the art of procurement mastermind event,

Kelly Barner (17:46):

Local language.

Greg White (17:47):

Yeah. There’s only one more word could put in there. That would be more that

Greg White (17:54):

That’s right. So Jaman, uh, I think had had a part during that event and, um, came back and told a lot of, uh, shared a lot of great news and great feedback with our team about his experience and, and how the audience, um, what y’all did there resonated with your attendees and whatnot. So now Greg, let’s segue into learning more about that event and some of Kelly’s key takeaways, we’ve teed it up. So good. So, so, well, sorry, we’ve teed it up. So tell us a little bit about mastermind 2020, and some of the key takeaways that either you got, or you feel like the audience came away with.

Kelly Barner (18:35):

Yeah. So mastermind live 2020 was sort of, um, in addition to all the other hats I wear, I’m the general manager, art of procurement and Philip I’d send for any of you guys that have listened to the art of procurement podcast. We have a mastermind membership community that’s focused around learning and round tables and learning workshops, very dynamic, but it was always intended to be virtual even before COVID, it feels a little bit odd to say it, but we sort of got lucky because we didn’t have to pivot. This was always the plan. And so for two days a week, last week, we threw the doors open. We welcomed absolutely everybody in. We had fantastic speakers in our event and we really tried to bring in some different perspectives. So for instance, we borrowed from you guys, we’d heard Stephanie to cover a customer experience on supply chain.

Kelly Barner (19:25):

Now she’s awesome, by the way. Um, and she was very kind because, you know, corporate procurement, we’re not really known for our customer experience. So when I sent her, so what exactly is your experience? She said, good to know where we’re starting, like tone, totally honest. And Jaman was fantastic. We had an opportunity to bring in a director from Thomas. Uh, some people might know them as Thomas net. They just recently released some research into PPE, which is something everybody’s concerned about. And so Jamie did a fantastic job facilitating that expert Q and a session for us. Um, but the big takeaways, I think of all the experts we brought in all the subjects we broached, it really was a very human event. Uh, what we heard from people was a lot of questions, but you might be surprised to hear a lot of positivity.

Kelly Barner (20:22):

There was a lot of energy. People were happy to be connected. If I had to pick a single word that I came away from the event from, I would say it was empathy. You know, even though we’re trying to manage costs and manage prices and stay efficient and do it from home. And there’s a lot of disruption, everyone is very focused around being empathetic towards internal customers, towards external customers, towards suppliers, towards employees. There are a lot of very real challenges going on right now to the extent that nearly every single category of spend product or service in an enterprise at this point has an HR twist. Almost every single thing has an APR consideration. Um, and I thought the best illustration of that was in a conversation we had around janitorial services, right? If you run a facility, you’ve always had janitorial come in.

Kelly Barner (21:17):

Usually it comes down to a cost-based decision. Cause as long as they’re providing standard services, they’ve got certifications. No worries. Well now guess what if your employees don’t feel safe, they’re not coming back, right? You were a difficult customer to deal with your janitorial service is not taking care of you right now. They have opportunities to go work for other people, and it’s no longer a lowest cost based service. So some of these things were completely shifting the way we think about them. It’s changing how we think about the value of these categories of spend. Um, but essentially we came away. I think people came away feeling energized, and that was certainly our goal to introduce new ideas. But, uh, we had times in between sessions, it felt more like a tailgate. Um, you know, procurement was just happy to get together. We had a contest actually to figure out who had sourced the weirdest thing. So, um, I won’t say her last name or her company, but it was Nancy and her company had to source bovine arteries. Wow. Gropes, I mean growth. So at that point we were just kind of done like bovine are actually

Scott Luton (22:41):

Real quick, uh, who again was part of the event, uh, and, and had a lot of good, great things to say about it. Almost everything has an HR twist, what you just shared there, Kelly. Wow. That’s so true. Now what has changed for sure. And I, I would echo that comment. Jaman great point there. And you know, we have Kelly shop with pro Terra on, on the show a month or so ago, and they’re a FA a very innovative vehicle manufacturer, a lot of public bus manufacturer, green bus manufacturer in the upstate of South Carolina. And she made a great remark that was so passionate and genuine where her role was VP of HR. That her charge that she takes very seriously is when she’s in those leadership meetings with C levels. And they’re, they’re throwing numbers around as if they’re just numbers and not people and families behind them. That’s her. She owns that to make sure that all the other executives know of the humans that are behind the numbers and the families that are behind the numbers. And now, you know, that really spoke volumes to, to the noble mission that HR leadership, his own, you know, and no necessarily means anything

Kelly Barner (23:46):

By it. It’s very easy, right. Where we sort of reduce everything to spreadsheets. If it fit into some number of boxes or squares or fields, you know, we kind of don’t know how to process it. So it is why it’s important that we have folks to remind us, let’s step back and think about this in a larger context, because no one intentionally says, you know, the hell with the people, right. Nobody ever goes being their approach.

Scott Luton (24:07):

Yep. We’ll put, all right, Greg didn’t mean to steal your thunder a little bit, that, that, uh, the people side of supply chain, we’re all passionate about that, right? Yeah, of course. I mean, when you think about other takeaways, anything else jump out at you?

Kelly Barner (24:22):

Yeah. I mean the positive ads, a few of the big statements that we heard, we had Jan Griffiths in, um, she’s from gravitas Detroit, um, a lot of experience as an executive, as a sort of a motivational speaker and career coach. She actually had us all stand up. We felt a little crazy, but when Jan tells you to do something, you do do it.

Greg White (24:43):

Everybody had to adjust their camera. I’m sure.

Kelly Barner (24:48):

Just,

Greg White (24:49):

Well it’s being exposed for wearing sweatpants.

Kelly Barner (24:51):

Yeah. Hopefully right. Hopefully boxers on the, on the group video. No, but so she, she did talk about, you know, needing to recharge ourselves, put on our oxygen mask first, before we can go out and do our jobs with the right level of enthusiasm. Um, and for me, the other huge takeaway actually came from dr. Marcel vulner, who is currently a partner at BCG. Um, and he pointed out if you’re not making the right decisions today, you don’t need a five year plan. I mean, that’s probably always true, but it’s really, really, really true right now. And you might be able to say, if you’re not doing the right things today, you don’t need a 12 month plan three months, even exactly. Right. So we can’t lose our focus on the horizon, but I think that horizon has moved in and we need to change our planning thoughts. But I thought, especially as we approach the end of the year, that thought has really stuck with me since last week, you know, the right thing today, or my longer term stuff. It’s just not going to matter.

Greg White (26:02):

We just talked yesterday with Mike Griswold, from Gartner and one of the, you know, they just had their, um, symposia supply chain symposium expo in Europe. And well, not in Europe for Europe. Of course, nobody does anything anywhere but home. But one of the key takeaways that he he had from that was if you’re only focused on surviving right now, the chances of that are very little, you need to focus on thriving in the future. You need to position yourself for success in the future. And that is tantamount to having a plan, as you talked about. Right. Um, and he talked about, um, um, a bi-directional, um, mode wherein you are dealing with crisis and at the same time planning and positioning for the future. Yes. So yeah. Very common theme, right. And appropriately. So yeah. Let me, let me share a couple of comments on some of what you’ve already shared.

Scott Luton (27:06):

Uh, Kelly, uh, let the audience weigh in a bit. So David loves the, your, your sentiment around HR. That’s what HR is all about. It’s not hard to worry about numbers and sometimes leadership needs to be reminded of that kind of what you shared there. Kelly, um, he also was wondering what the bovine hearts are being used for that the strangest sourcing award. Uh, let’s see, Ehrenfried says that can be tough with a servant leader mentality. You get so focused on taking care of the people around you that you forget about taking care of yourself. And, um, Amanda and clay loved what you shared there about, you know, putting our oxygen mask on first. Otherwise you can’t help anyone else, right. By the way, to what Erin is talking about is you have to at least provision foundationally for yourself. You can’t drag someone out of the flood if you’re, if you’re swimming in the water with them. Good point, good point. And finally Jaman says he learned a ton from Kathy ma I think Katherine model was with Thomas net. And I believe she definitely brought energy and humor, which helped. And we’ve, if we’ve said it once we’ve said it, a thousand times, Kelly, we’ve got to maintain a sense of humor and in a historically challenging year, like 2020, right?

Kelly Barner (28:21):

Yeah, no, we do. And I think part of why, and this break even connects the empathy with the humor, with the oxygen mask. Is it so much of the work that we’re doing right now is creative. We’re not doing a lot of formula leg. I mean, if you’re a framework person you are screwed right now, we’re just not a lot of frameworks working right now. And I’ve heard a lot of stories about teams and their leaders that are amazed with what their teams have risen to the occasion. And Don and it’s working in weird situations. It’s balancing family and business it’s, um, nights and weekends and you know, uncharted territory, but that is more exhausting than sort of walking down the path. Um, and so it is all the more important anyone on the leadership position, anyone with a regularly creative position, we do need to have those times, because as you were saying, Mike pointed out, Greg, if we don’t find some way to productively get through this time that we’re in and that’s almost worse than not needing a five year plan, that’s, you’re going to be burned out in six months and on short term disability, but it needs to be sustainable in the sense that we’re making good decisions.

Kelly Barner (29:37):

We’re getting the right things done, but we need to forgive ourselves. We need to set fair priorities. We need to unplug on occasion, even though it feels like the wrong thing to do because you get them today, but we also need to be ready for tomorrow. And so many of the things that we’ve probably taken for granted in the past, we need to force ourselves to stop and rethink them if we’re going to get through this time. Okay.

Scott Luton (30:01):

Yeah. I call Tom out and challenge some of these long running assumptions we’ve made or, or our best practices, air quotes, you know, everything’s changed as we, and we, Kelly, uh, an interesting visual that we’ve embraced in recent weeks, Greg was just like, one minute we’re playing chutes and ladders with one set of rules. And then the very next minute we’re leaping to monopoly. And which of course you can’t play by the same rules, completely different game. And that’s on some level, that’s kind of where we are, especially in retail, for example, you know, so I love your sentiment there. All right. So Greg, um, let’s keep driving here. Well, and one thing I think when we talk about empathy and we talk about leadership and we talk about creativity, we have to acknowledge also that stability is required for some people accountable, creativity. I mean, not totally, but, but the creative people who are solving these problems need to rapidly deploy, uh, adaptive processes, adapted processes to those people whose jobs stability is.

Greg White (31:11):

So we need to be, we need to acknowledge that as well, but you’re right. We do need to change things. And then we need to at least tentatively deploy a standard methodology wherever we can or need to because not everybody approaches this stuff or has the same needs in their jobs. So, um, so anyway, let’s talk about some of that adaptation, because we’ve been talking about a lot of that. I have no doubt that this topic has come up as often for you, as it has for us. I bet you know where I’m going, but let’s talk about things like near shoring, shoring and China plus one or whatever, multiple sourcing, those sorts of things. So give us some of your thoughts there.

Kelly Barner (31:57):

Sure. And it’s, it’s actually funny, Greg, that you asked this question of all people, because I feel like in the grand scheme of things, it was about 15 minutes ago. It was months, but it feels like 15 minutes ago, I heard you talk about China plus one. And I was like, what the heck is China? Plus one early enough in this whole thing that I’m thinking, okay, well, Google has all the answers, right? Google kind of didn’t know there wasn’t a ton there for me to draw from. Um, and so, okay, well, if Greg’s talking about it and I got to know what this means within 24 hours, China, plus one, it was everywhere. It was the only thing. And it was so reactionary. And so that’s, you know, maybe let’s say March, April. So, you know, we went through all the headlines were sort of like everything, all manufacturing is coming back to the U S all sourcing is going to be near shore.

Kelly Barner (32:53):

Everybody wants to know who can supply something within walking distance of my facilities and had this kind of like emotional nature. And what I’m starting to hear is this is actually the good side of the fatigue. Fatigue does have a way of bringing you back to basics. It brings you back to reality and you think, okay, but do I have any idea how much that’s actually going to cost? And when you start to think about that, whether your talking about nearshoring or whether you’re talking about having a prequalified, potentially contract and secondary source of supply, it’s expensive to get there. It’s expensive to keep it. And it may be expensive if you need to use it now, the additional cost, if you need to use it, maybe justifiable, but then it’s like, okay, how long is it going to be? Am I definitely going to need it?

Kelly Barner (33:49):

To me? It sounds like we’ve moved on to a refinement of that initial area where it’s no longer just everything overseas or even everything China specific is terrifying, and we don’t want to do it anymore. Now. We’re like, okay, when I actually look at where were things, the scariest, and also how fast did things come back online? I’m hearing some very interesting things that I wouldn’t have expected. I interviewed a CPO yesterday who was talking to me about how, um, they do some sourcing in China. Well, they also source in India and they source in Mexico. And he said, you know, we were mostly scared about China, especially early on. They went in with some surplus inventory to this whole thing because the Chinese new year, it was kind of fortunate timing. A lot of companies did that. The speed with which China came back online, know all the emotion that went into the panic was sort of like, okay, well maybe that’s not our biggest concern.

Kelly Barner (34:49):

What they really saw was that other countries. And he gave me the example of Mexico specifically based on the industry that he’s in the struggle to get back online. So it’s not even the initial disruption. It’s, it’s the long tail impact that follows it. And so to me, I think it’s good where exhausted. And we’re going back to looking at what are the fundamentals, what’s the actual impact. And then let’s get a little bit more nuanced, right? So just like we talked about, okay, GPO is awesome for some things, not the right approach for other things, same deal with whether it’s localization nearshore in China, plus one, just China backup supplier sole source. We can’t have the same response in every category of spend with every supplier and every geography. We’re more strategic than that. It needs to be a lot more nuance. So I really feel like things are starting to swing back to the reality of, okay, but if we re optimize for this new world, even if it’s just for now, let’s do a three or six months, right. Kind of plan. Let’s look at the numbers. Sometimes you have to just look at the numbers and let those lead the way. And I’m glad that we’ve moved away and it’s become more of a discussion because for every company it’s going to be different and nothing in procurement or supply chain goes better. When you make a decision emotionally, that’s never met.

Scott Luton (36:18):

Let me add one piece of context to some of our, our listeners or audience members that may not be familiar with, with finding and sourcing suppliers, vetting them, and then bring them on board. You know, we saw very large organizations, uh, aircraft organizations and others that were paying bills earlier to protect the suppliers they had in when one of those reasons is because it is, especially in those highly demanding industries and sectors like automotive and aviation and healthcare. It’s tough to find, uh, suppliers across the globe, much less within walking distance of plants that are quality are going to, and that are going to deliver on time and every time, and then onboard them into your, your complex global supply chain. I mean, that’s, we’ve got to think about all the levers that you’ve got to pull and adjust when we were talking about moving, uh, global supply chains here and there.

Scott Luton (37:10):

Greg, I know a lot of what Kelly just shared. You’ve got, I see about seven bullet points in your mind right now you’d like to share, respond to, but give us a couple. Yeah, well, the immediate one that comes to mind is, uh, I must have worked with some really, really exceptional supply chain organizations and professionals, because they’ve always had a plan B Chick-fil-A though. They didn’t, at one point they just felt the slightest threat to their supply chain and diversified. Um, and, and, um, other organizations had a, you know, I worked with so many organizations who had to have a backup plan. They actually had policies where, and, you know, we built technology to support. This is why I recall it. They would give 70 or 80% of their volume to the primary vendor, but always keep someone on the hook, maybe multiple someones on the hook for that 10 or 20%. So that, that person had reason to be engaged with you if a crisis happened. Right. I remember one of the quotes we saw early in this whole thing where somebody said, it’s too late to make friends now. Yeah.

Kelly Barner (38:23):

Yeah. Nobody wants to be the newest customer 30 days for pandemic, the newest vendor.

Greg White (38:31):

They’re like, where were you when we needed you? Right. Hey, go ahead. Sorry. Well, and, and, um, this whole hysteria around near shoring and reassuring and all of that, Scott and I, you know, we talked about that aspect of it, uh, very early on. I try to be very level having been in supply chain for over two decades. And that’s all I’m confessing to. Um, I try to be very level in responding to these things because of the foundational issue in supply chain is these huge pendulum swings save money, customer experience, save money, customer experience, and the, you know, the fact that it is a novelty to some people in supply chain and procurement, if you can even separate the two anymore, that you can do both and you need to work for a balance of both and, and, um, saving money that was over here, right.

Greg White (39:27):

Doesn’t necessarily mean that you can’t have great customer experience, right? If you have to trade off your policies and your processes that are foundationally flawed, because there is an ability to reach that more than happy medium. I mean, I worked with companies who reduced their inventory by 50% while increasing sales by 20% a year. So I know that it can be done. So I know we also know Kelly’s got a hard stop here in about five and just a few minutes here. So we want to make sure folks can connect back and find Kelly, but Kelly real quick. Let me share a couple of comments here. Uh, Mike gave her, says we used to use ups for 80% of shipments, but kept DHL on contract for 20% because of the strikes UBS had 20 years ago. So we could always have a carrier. There you go.

Kelly Barner (40:18):

Meeting point, because that actually is a little bit how, if you’ve ever heard anybody talk about having a grandparent who lived through the depression? Oh my gosh, forever. You live through a strike. The experience is with you forever. None of us going through this right now are ever going to manage supply chains the same way again. Yeah.

Scott Luton (40:35):

Great point. Uh, Barb with Omnia shares, nailed it. Kelly, get back to the fundamentals and explore all options and resources. I love that Barb and great to have you here with us. So [inaudible], um, I don’t want to cover you up Kelly. We’ve got some great input coming in from your father. He basically says, what do you get? If you play a supply chain, country, song backwards, you get your revenue back, you get your margin back, you get your own time delivery back. The decisions that supply chain folks make when there is nothing to base it off of, other than, for example, the Spanish flu, it really creates a real supply chain mess for companies that do not have a plan B will said their neurofibroma AA says supply chain. Now I keep wondering reporting or influencing just the facts, just the facts and a little bit of opinion, maybe a professor and not, yeah. I mean just the opinions based on the facts. That’s right. There you go. Sylvia are one of our, uh, Kelly. Sylvia is resident,

Scott Luton (41:34):

Uh, King of jam production. She’s based in Charleston. She’s also a wonderful leader and practitioner. She says, she’d love to hear about her success stories during the pandemic. It looks like they’ve got an organization. JCC South has been a great resource for her to find that sound balance between labor law regulations and the needed changes for your team. Some Greek simple reclassification of non-exempt to exempt status, good stuff there so much to cover Kelly. I knew that it was going to be a fast paced, um, uh, conversation day, but we’re going to have to have you back. Congratulations on yet. Um, you’re like Ty Cobb or, um, uh, Joe who’s, um, showing, um, 57 game baseball history knowledge. I can’t think of a famous Yankee that currently holds the all time hitting streak. Um,

Kelly Barner (42:27):

That’s cause I’m from Austin. It’s my boss erasing. Don’t give her Yankee

Scott Luton (42:33):

It’s DRAM ski or, um, um, uh, anyway, what my point is you you’ve had a string of hit hit after hit, after hit and mastermind. A block of 2020 scenes seems to be just the latest one. How can folks connect with you and, and be a part of this, this, this global community you’ve been building?

Kelly Barner (42:54):

Yeah, absolutely. There’s a bunch of ways. Um, buyer’s meeting point on either LinkedIn or Twitter, uh, me personally on LinkedIn Kelly Barner, or you’re certainly welcome to email me Kelly at buyer’s meeting point.com all of those ways. Uh, um, I’m always looking forward to hearing from people. So please do reach out if we’re not already connected. Um, we can either continue the conversation or we can simply just follow each other’s trends on social

Scott Luton (43:20):

Outstanding Kelly, uh, always a pleasure to reconnect. I really appreciate our whole team appreciates the thought leadership you’re putting out there. Greg, we’ve got just under two minutes, Kelly, final shot,

Kelly Barner (43:32):

Final shot. Be good to yourselves, do not lose face that we’re going to get through this. And also don’t forget to challenge yourself because next week is not today. And next month is not this week. You are making assumptions and optimizing based on constraints that are going to expire very, very quickly. And so don’t be afraid to reexamine any of your own decisions as well. That is my, that’s my big advice that applies to all this love, that price of admission. Thank you. Thanks for having me guys.

Scott Luton (44:09):

You bet really, we we’ve enjoyed talking with Kelly Barner amongst other things, owner and managing director with buyer’s meeting point. Thanks so much, Kelly. And I love talking with Kelly. She, uh, she has, it’s interesting how quickly she can, uh, process what’s being said and give you a hot that is as good as what Greg white gives you with his hot take. Uh, you know, I learn something new every time sitting down with Kelly and, and of course the procurement space in particular being as, uh, critical and uh, in the equation right now. I mean, this is, um, a lot of good stuff delivered here today by Kelly

Greg White (44:50):

Suddenly don’t you feel very validated that Kelly agreed with our early on predilections regarding COVID and all of that. I feel so much better knowing that she agrees, I almost feel right.

Scott Luton (45:06):

Well let’s so, and cylinder audience members are speaking those lines.

Scott Luton (45:10):

And, uh, let’s talk about that.

Scott Luton (45:12):

Yeah. And thanks Mike, Ava and clay, uh, Joe DiMaggio. How could I forget the Mazzeo?

Greg White (45:19):

You didn’t mention yet another Yankee to a red Sox fan. That’s true. I should’ve said Ted Williams, maybe.

Scott Luton (45:26):

Hey, Wade mugs. Okay. So Francoise shares the entire mentality of a quote unquote simple shift is based on the panic

Scott Luton (45:36):

Through uncertainty. This should be

Scott Luton (45:38):

Long term proactive initiative rather than a reactive shift. Most reactive shifts I’ve seen have been wildly costly and unsuccessful.

Greg White (45:47):

Nice. So just a thought because Kelly brought this up, she brought up, um, the depression in the United States. I would encourage folks to go to whichever it is Netflix or Amazon. And watch just that. I think it’s just a two or four episode series about the dust bowl from my part of the world, a constant seven year disruption. Um, and just about the time you thought there was hope, hope was dashed and, and the mentality that came out of that, my great grandparents and grandparents were alive till I was 23 or or later. Um, and, and I heard about that. It’s funny that she mentioned that being raised by people from the depression, it was very interesting, their perspective, but they were never, ever, ever caught on the back foot. Again, they were very level. They responded to things as Francoise is addressing. And I think, um, as, as Kelly says, we’ll see a lot more of that, especially now, right? This is a very hysterical and hyperbolic time. Everything is a big deal. We have to acknowledge that while a big deal, as a great friend of ours said, and I can’t guarantee this is his quote specifically, let’s not sit back and admire the problem. Right. Let’s move ahead. Let’s keep driving. As you say, Scott, and, and let’s progress in the, in the situation that we’re faced with. Yeah.

Scott Luton (47:14):

Yeah. We’ll put a, you know, paralysis by analysis or paralysis by just, um, despair or, um, uh, uh, you’re blown away with the size of the challenge you’re facing. You can’t, can’t get distracted with that kind of stuff. I’m want to say a low also let’s see here, Sylvia says it takes three and a half years from Greenfield to start a production near shoring and insuring are nothing but buzzwords right now. Interesting there, Tom says Kelly’s point was spot on. We’re going through an anxious time. It is super important to be aware of that when dealing with people and be empathetic to the fact that they are likely going through stuff. Well, we’ll said there, Tom.

Scott Luton (47:54):

Yeah, very well. Yep.

Scott Luton (47:57):

You know, um, it’s front and center more. I think this, this empathy that Kelly’s talking about, I think it seems like a lot more folks are embracing that and being aware of the challenges you might see behind the zooms and behind the conference calls and behind the emails. So that’s good stuff there. Gary Smith, I always have a plan B or C or D creed. Um, we gotta say low one of our favorite people, uh, Jenny Froome is with us from the outstanding say picks organization. Jenny hope this finds you. Well, I think they’re on YouTube and we’re looking forward to collaborating with you in November.

Greg White (48:33):

Yeah. And still awake because it’s late her time. It is late her Thomas. Right.

Scott Luton (48:39):

So Greg let’s before we wrap and Hey to our audience, I know that as we get later in the hour folks, uh, that the emails are piling up and, and conference calls start again, maybe after you’ve had a chance to eat, uh, eat a sandwich. But if you share one thing, one of your key takeaways from what Kelly Barner was sharing with us earlier today, I’d love to read through those. Um, but Greg, we’ve got a little bit more work to do some more heavy lifting to do. Let’s talk about the automotive industry action group

Scott Luton (49:10):

Ag supply chain summit. Yeah. Well, we’ve been doing interviews for, for that summit with some fantastic people yesterday. Can I say yesterday, we interviewed someone from Ford motor company. Uh, what would you guess? 24, 25 years old and amazing mind and future leader of probably America, but definitely within Ford working on their electric vehicle programs. So blown away. Amazing. I was yeah. Amazingly intentional individuals. So it’s that kind of thing that you’re going to get. It’s not just automotive and that’s what I felt was purpose driven. Intentional. I’m obviously a big fan of automotive and working for one of the largest, uh, companies in the world. But that the value of that, as we’ve said, automotive can teach us all a lot about procurement and about supply chain in general about plan B’s and C’s and D’s yep. And about deeply tiered supply chains, they have as much as seven tiers of suppliers in, in automotive. So man, listen up. Yes,

Scott Luton (50:25):

Definitely. Hey, we’ve got to say a little Kim winter is with

Scott Luton (50:28):

Us. So Kim, uh, leads a global, uh, recruiting and, and uh, talent group. He also has a great video podcast. You can check him out at a via YouTube, but Kim, great to have you here. We’re looking forward to reconnecting soon. They’re also sleeps cause it’s eight hours. Plus they were going back to Jenny. Jenny says it’s only 7:00 PM. I knew I should have broken out my advocates as I try to calculate. She was confusing her location with Dubai actually. Yeah, it is a one last note on this AIG thing. Cause it’s really important folks. They make it really inexpensive, especially in these talent and you know, challenging time. Some folks were still dealing with quarantine and lockdown, you know, $49 for a nonmember to really engage in kind of that community that Kelly was describing. It sounds like was really successful with her event.

Scott Luton (51:20):

You know, you’re not only can you learn best practices, but you can connect with folks and, and feel more connected to what’s going on in industry. So we’ve got the link to this event. It’s coming up in November, November 5th. Uh one-click in the show notes, y’all check it out and we’d love for y’all to join us there at that event. All right. So we’ve got a couple of the comments Greg, I’m going to throw down, lets you comment on. So AA says, Hey, adding your comments, Scott, keeping aircraft supplier partners, financially mobile is a good trade off. It takes a lot of effort to create a reliable supply chain for an aircraft BLM restructuring the network for even a component or it’s critical tear down parts becomes more, uh, very expensive to say the least completely agreed. You’re familiar with that professor cause you’re an air capital, uh, uh, city of the world where they have a lot of aviation manufacturing, gold Greg’s hometown, but great point, Greg, elaborate on that.

Greg White (52:17):

Well, I see it firsthand. My very best friend in the whole world. Brian detain is, um, he is, you just shot me in the heart, Greg, you just absolutely my very best, best friend in Wichita, Kansas, how’s that, um, he works for a tier two or tier three supplier. And I have heard stories over the occasional cold beverage, um, about how difficult it is for them to source. So they source landing gear and other component parts of aircraft and uh, the intricacies of that and the, the number of parts that go into a bill of materials, there is unbelievable. But I think it goes to the principle of that. You were talking to Scott around supporting those most mission, critical, those, those critical path suppliers, you can’t job without them at the very least, right? At least be kind and supportive of those, you know, has nothing to do with aircraft. But I did a study some years ago, the best customer to have, um, as, as a procurement organization, if you’re a supplier, is the Billy Graham organization. They always pay their bills 10 days early, every single time. And whenever they need anything from their suppliers, they get it. So if you, you don’t have to do that, but if you, if you treat your partners fairly, they’re going to treat you more than fairly in return, right?

Scott Luton (53:48):

Yeah. Great point. Yeah. The, the, uh, the bomb as a P folks refer to it, bill of materials, massive. I mean, think about all the different components and parts that go into a, a multimillion dollar aircraft. And of course it’s got to keep it in there, right?

Scott Luton (54:06):

Yes. Right.

Scott Luton (54:06):

That’s right. So a great point a I appreciate you making it, Hey, Nearpod says automotive has been as bread and butter for the last 10 years.

Scott Luton (54:14):

So he’s gonna take a look at yeah.

Scott Luton (54:16):

AIG and you know what [inaudible] um, maybe they can add you to the program for a little extra

Scott Luton (54:22):

For levity, right? He is in Windsor, literally. If they were doing this physically, he could drive across the river to Detroit and go there. Well, um,

Scott Luton (54:33):

Alright. So, uh, really enjoyed Kelly. I knew we wouldn’t have enough time to get to all the different things that she could speak to oriented grant to have her back. And that procurement space is such a fascinating, a space always has been, but even more so right now, would you agree?

Greg White (54:48):

Yeah, undoubtedly, I mean, if, you know, as much light as it is brought in, brought on the broad supply chain, um, you know, we have heard some absolute horror stories in regard to the specifics of procurement, right. Vendors going away or, uh, goods being stripped away by new or, or, or current customers. Yeah. I mean, it has brought incredible disruption to that marketplace. And at the same time, I got to tell you, we have seen some amazing adaptation, uh, in, in the procurement space. But yes, I have never heard so much about procurement as I have this year. Right.

Scott Luton (55:31):

I completely agree. Scrolling back up to there’s some of the comments here at new, we were talking about the board game switcheroo and Dave and says, uh, and, and when you’re switching from chutes and ladders, some Napoli you’re, you’re missing half of the pieces to the monopoly set. That that is kinda what it feels like a lot,

Greg White (55:47):

Dave, and go in your kid’s toy box. David, probably the bottom. So

Scott Luton (55:52):

I was talking about, uh, getting, uh, getting things 10 days early, which cuts down on the cash conversion cycle. I’m not sure if he’s referring to something you or Kelly said,

Scott Luton (56:03):

Uh, Greg, or maybe the grant organization pays their bills 10 days early. So, um, they weren’t worried about, um, that the truth is this whole dragging people thing, it doesn’t create cash. It just shifts when you pay the cash. If you think about it. Yeah. I worked for a retailer that, that we routinely,

Greg White (56:24):

And as a matter of course, dragged our vendors, which meant paid them 10 to 30 days late. And all that did was shift that cash outflow by 30 days, it doesn’t change the cash cycle as right. Yup. Good point creates a bunch of ill will amongst other things. Let me assure you. So, Hey, um, we’re gonna be wrapping up today’s livestream. This has been a, what a week of live streams. I think we knocked out for this week, if I’m not mistaken, Greg. Um, but to our audience, I’ll check out if there’s something that we mentioned that you can’t quite find, um, or any of our shows, anything we talk about, you can go to supply chain now.com and learn a lot more information. You can even hit us up via the website, really have enjoyed, um, all the comments and engagement we’ve had, uh, this week throughout all the live stream programming, as we look to fulfill, uh, fulfill our mission of giving voice to all of those that are moving, moving stuff, making stuff, um, procuring stuff, sourcing stuff, handling returns, you keeping the whole global supply chain moving forward.

Scott Luton (57:33):

Which of course Greg protects the consumer psyche during a year, like 2020, right? Yeah, no doubt. Yeah. I mean, um, the, the reason that supply chain is in the forefront of things is because it should have always been in the forefront of things, frankly, but this has just been a catalyst toward that. Yep. Agreed. And you know, we’re, our team is passionate about that. So I love that point. That’s a great point to end on. So to our audience, hopefully you enjoyed, uh, Kelly Barners, uh, thoughts as much as Greg and I did really appreciate you bringing in the comments and, and bring in that voice. Our audience is one of the brightest out there and they always deliver. Um, so, uh, to all of our audience members, Hey, we’re wishing you all the best here. All the best of our team on behalf of Greg white and our entire team here, Hey, do good give forward and be the change that’s needed. And on that note, we’ll see you next time here on supply chain Now.

Featured Guests

Kelly Barner is the Owner and Managing Director of Buyers Meeting Point and MyPurchasingCenter. She has been in procurement since 2003, starting as a practitioner and then as the Associate Director of Consulting at Emptoris. She has covered procurement news, events, publications, solutions, trends, and relevant economics at Buyers Meeting Point since 2009. Kelly is also the General Manager at Art of Procurement and Business Survey Chair for the ISM-New York Report on Business. Kelly has her MBA from Babson College as well as an MS in Library and Information Science from Simmons College and she has co-authored three books: ‘Supply Market Intelligence for Procurement Professionals’, ‘Procurement at a Crossroads’, and ‘Finance Unleashed’.