Procurement is about connectedness: working with different stakeholders and then coming up with the best outcome that in the end becomes a win-win. Your suppliers are happy, and you are happy as an organization, and you can both be successful together.

- Joel Solomon Senior Director of Strategic Customers at SAP

Episode Summary

Demand for sustainable, connected, and autonomous products is growing exponentially, forcing sourcing and procurement departments to keep up with new innovations while balancing costs. But there is a better way.

New digital technology can help procurement teams in engineering-centric industries like automotive and industrial manufacturing to streamline their sourcing and contracting processes and better control material costs during new product launches and ongoing parts procurement for mass production.

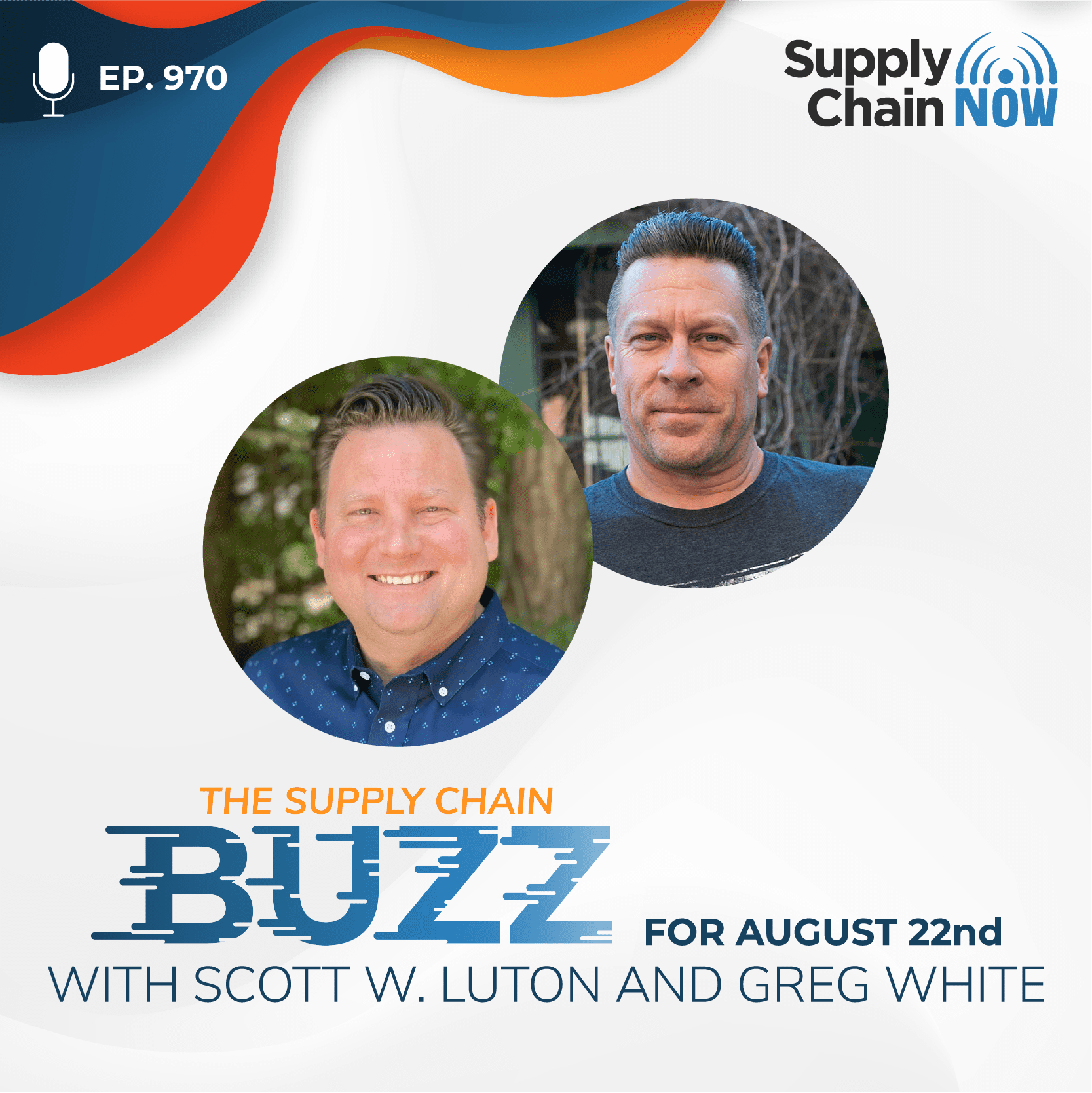

Joel Solomon is the Senior Director of Strategic Customers at SAP and Carsten Wutzler is the Director of Enterprise Performance at Deloitte Consulting. They recently joined co-hosts Scott Luton and Allison Giddens for a Supply Chain Now livestream to discuss best practices from leading automakers and industrial manufacturers.

Watch or listen to this episode to learn how leading automakers and industrial manufacturers are:

– Supporting and scaling on-time product launches and ongoing procurement of highly engineered parts

– Collaborating more effectively with suppliers to meet new innovation requirements

– Managing material costs from launch through ongoing production and beyond

– Leveraging ERP investments and extending them into procurement processes to drive more supply chain flexibility

Episode Transcript

Intro/Outro (00:04):

Welcome to Supply Chain Now, the voice of global supply chain. Supply Chain Now focuses on the best in the business for our worldwide audience, the people, the technologies, the best practices, and today’s critical issues, the challenges and opportunities. Stay tuned to hear from those making global business happen right here on Supply Chain Now.

Scott Luton (00:32):

Hey, good morning, good afternoon, good evening, wherever you are. Scott Luton and special guest, Allison Giddens, here with you on Supply Chain Now. Welcome to today’s livestream. Allison, how you doing?

Allison Giddens (00:43):

I’m good. I’m good. How are you?

Scott Luton (00:44):

I’m doing wonderful. We’ve got — I’ll tell you, we’ve set the bar high after last Tuesday’s wonderful event. We’ve got a lot of feedback on, you and me, the — quite the duo. We’ve got another big show here today, right?

Allison Giddens (00:56):

Yes, we do.

Scott Luton (00:58):

All right. So, Allison, great show of line up today. We’re talking about, get this, faster, cheaper, better. Who wouldn’t raise their hands for that? Sign me up. Well, today’s show, Allison, we’re going to be sharing some effective ways at leading automakers and industrial manufacturers are implementing faster, cheaper, better, successfully into their operations and overall enterprise. Allison, you ready for our great show here today?

Allison Giddens (01:22):

I am. I’m excited.

Scott Luton (01:24):

All right. So, folks, stay tuned as Joel Solomon and Carsten Wutzler will be joining us momentarily. And folks, get ready, we want to hear from you too. That’s one of our favorite parts, in addition to the knowledge that Joel and Carsten and Allison will be dropping on us.

Scott Luton (1:39):

All right. So, I want to welcome in our featured guests here today, Joel Solomon, Senior Director, Strategic Customers with SAP. And Carsten Wutzler, Director, Enterprise Performance with Deloitte.

Scott Luton (1:53):

Hey. Hey, Joel. How you doing?

Joel Solomon (01:55):

Not so bad, Scott. And, thank you for having me, both you and Allison.

Scott Luton (01:59):

You bet. Welcome, welcome. And Carsten, how are you?

Carsten Wutzler (02:03):

Hello, from my side. Doing good. Thanks for inviting us.

Scott Luton (02:05):

Well, you bet. We got a great conversation. And so, thanks to you both for being here. And we’ve got a lot of folks from Juan in Dubai, Kaya in Chicago, Lindsay from Grand Rapids, Michigan, Paul up in Chicago. A lot of folks here already for a conversation around faster, cheaper, better.

Scott Luton (2:25):

But before we get there, Joel, Carsten, and Allison, this is what I want to do. I want to have a little fun, I want to pose a little fact toward with all three of you all. So, yesterday, that’d be June 5th, back in 1977, the iconic Apple II went on sale for the first time, right? Now, so, for me, that is synonymous with the Game Oregon Trail, which I played for hours and hours in elementary and middle school. So, anytime I hear Apple II, I think of Oregon Trail.

Scott Luton (2:52):

So, for each of you, and Joel I’m going to start with you. What is one ’80s or ’90s technology device that brings lots of memories to mind?

Joel Solomon (03:00):

I’ve got to go with a Sony Walkman, Scott. So, that was given to me on a birthday of mine. And I took it everywhere with me, including to practice for my sports and just cool and everywhere else. So, that was absolutely a game changer for me and I was absolutely mesmerized by it.

Scott Luton (03:18):

So, Joel, that begs the question, what’s one tune that you can still remember dancing to on your Walkman?

Joel Solomon (03:24):

Well, I don’t want — I don’t know if I have to admit this, but it was a tune from ABBA.

Scott Luton (03:29):

OK. I can see it.

Joel Solomon (03:32):

It was Dancing Queen.

Scott Luton (03:35):

So, Joel, man. All right. We’re going to have you back on supply chain nerds talk music in a future live stream. Good stuff.

Scott Luton (3:42):

Carsten, how about you? What ’80s or ’90s technology advice comes in mind for you?

Carsten Wutzler (03:45):

Yes, I fully agree with Joel. So, the Walkman is one of the most recognizable elements of this — of the past. It later changed to a Discman, yes. And I walked outside just to use this device and come back at home and had some music, and it was really good then. And I listened to Europe, “Final Countdown.” Not sure if you’re familiar with the song, but it was one of my favorites, the first CD I bought, and yes.

Scott Luton (04:11):

Of course, Carsten. “Final Countdown”, it’s one of my son’s favorite tunes of all time. So, thank you for sharing, Carsten. All right. So, a big music vibe so far in this show.

Scott Luton (4:21):

Allison, how about you?

Allison Giddens (04:23):

All right. So, I was going to say the ability to use like a tape to put into your tape deck in the car so that you could use your CD Walkman. I was going to say that technology, but just to be different. How about that? 1997, the release of the first Tamagotchi? Remember those stupid toys? I mean, you’re talking about memories. My sister and I, we would — we’d get those things and we would be so excited and they’d die in like three days because we’d forget to feed them

Scott Luton (04:54):

Alright.

Allison Giddens (04:56):

So, it might be a reason I’m not a mother today is —

Scott Luton (05:00):

Those are, like, the electronic pets, you’re talking about, Allison, right?

Allison Giddens (5:03):

Yes.

Scott Luton (5:04):

OK.

Allison Giddens (5:04):

Yes.

Scott Luton (5:05):

I got you. Man. That is —

Allison Giddens (05:06):

You remember those things, right?

Scott Luton (05:07):

I do. That’s a pool. That is a — so, get this Allison, Joel, and Carsten. So, Jerry’s talking about, of course, the VCR, that was an interesting. VCR, Betamax contest. Kaya, of course, the Macintosh computer. Yes. ClarisWorks was a big part of my high school experience. Juan, scientific calculator.

Allison Giddens (05:28):

Oh, good point, yes.

Scott Luton (05:29):

John Peterson, the Super Nintendo.

Allison Giddens (05:30):

Heck, yes. Heck, yes.

Scott Luton (05:32):

Awesome. Good stuff.

Scott Luton (5:34):

All right. So, we can really reminisce for quite an hour. But we got a lot to get to here today. One — we got to sneak in one more. Amanda says, the discman was huge. Also, as a mom, the DVD player in the SUV. Yes. Strategic distractions — strategic distractions, Amanda.

Scott Luton (5:52):

All right. So, Joel, Carsten, Allison, a lot of stuff to get to. This is what I want to start with though. Before we get into some of you all’s industry observations and really proven best practices that you’re seeing out in the industry, I want to give our audience a chance to get to know you, Joel and Carsten, a little bit better.

Scott Luton (6:06):

So, Joel, you’ve been moving some mountains in the industry. Tell us about yourself and your journey.

Joel Solomon (06:10):

Yes. So, my name’s Joel Solomon. And I’ve basically been in the procurement and supply chain practice for most of my life. I started off my career with Honda after I graduated from my mechanical engineering. And I fell into procurement, and that’s when I realized that this was an absolutely cool space to be in. I really loved the fact that I could interact with people, also with technical aspects of procurement and vendor development.

Joel Solomon (6:37):

And from there, I moved a few different roles as well, and moved to countries. I moved from India to Australia. Picked up my MBA, and also got certified in supply chain through Apex. And ended up working for a couple of mining organizations before coming back to automotive, where I was the head of procurement for Volkswagen Group in APJ based out of Sydney, Australia.

Joel Solomon (06:59):

And I loved procurement. I loved the power that it gave me as an individual, but also the fact that I could influence the world, influence people. And about five years ago, I moved to SAP on the other side of the spectrum from buying to now selling, from beating up suppliers to actually getting beaten up by suppliers.

Joel Solomon (7:22):

So, it’s been a great journey. And I’ve seen some wonderful transformations in my career. And I’m also fortunate enough to work with clients and have the privilege of influencing their own journey. And thank you for having us here, and I love to be part of this session and share my experiences as we go along.

Scott Luton (07:40):

Oh, Joel, man. You really — I love it already. I can tell that you keep it real. You keep it real and you love what you do. Clearly, you realized how cool procurement was long before the rest of the world did.

Scott Luton (7:52):

All right. So, Carsten, same thing. You’ve been in the industry, it’s not your first rodeo, tell us a little about your journey.

Carsten Wutzler (07:57):

Yes. Hello from my side. I’m Carsten, working at Deloitte. I’m based in Germany in Munich. So, I started after being — graduating as an industrial engineer, equipped with some business backgrounds in administration. I moved to consulting and started 17 years back in this exciting industry. Always being part of the operations and supply chain domain.

Carsten Wutzler (8:20):

And along this journey, I worked primarily for the automotive industry, which has been a big part of my professional career and took me to some interesting manufacturing locations. I had the privilege also to work for consumer guts [phonetic] and, industrial products companies, high tech, and some medical device clients.

Carsten Wutzler (8:38):

My focus has always been on enterprise performance and the supply chain management. And most of my projects are really around business process transformation, end-to-end optimization, performance management, and of course, digitalization. And over the years, the procurement area has also gained my attraction, and I really got expertise in categories and did some sourcing optimization work and acted as a negotiation trainer.

Carsten Wutzler (09:04):

And actually, this expertise brought me to my first U.S. related procurement project where I was part of a sourcing program for beer ingredients and packaging. And someone on the project thought it would be a good idea to invite some person from the beer drinking nation Germany and lift the credibility of the team, and it was really fun. However, the market demand for automotive and complex manufacturing topics is much higher. And so, I met Joel and SAP long time back. And happy to be here in the supply chain community as an expert and share my expertise.

Scott Luton (09:38):

Carsten, I love that. And beer drinking helps any negotiations. Is that right, Allison? Right?

Allison Giddens (09:44):

Well, yes. I guess. I’m not a beer drinker. I’m more of a vodka person, but I mean, I’ll hang out and watch you drink beer.

Scott Luton (09:51):

OK. All right. Well, clearly tons of expertise and experience and a nice sense of humor. Both of you all fit right in, kindred spirits. Now — OK. One last comment before we keep driving here. So, our dear friend Tim Porterfield, says, Allison, got to know your first CD. Allison says, a Veruca Salt. How about that? I remember when that album came out back in the day.

Allison Giddens (10:14):

A little ’90s grunge, yes.

Scott Luton (10:15):

’90s grunge. Not quite as cool as ABBA, Joel. Not quite as cool.

Allison Giddens (10:19):

No, no.

Scott Luton (10:19):

But — all right. So, clearly musical is going to be a big overarching theme here today.

Scott Luton (10:24):

All right. So, Joel, Carsten, and Allison, this is where I want to go next. I really want to set the table for our conversation. You know, this is a — you know, there’s part — there’s no easy times, right, in global supply chain, right? Disruption, it comes with the territory. Curve balls keep coming around the corner. So, I want to get a couple observations from both of you.

Scott Luton (10:40):

And Joel, I’m start with you. In terms of current priorities for business leaders, regardless of the sector, what do you see in business leaders gravitate to and prioritize?

Joel Solomon (10:49):

I’d probably think of three themes that come to my mind, Scott, as we talked to business leaders from around the world. I do have a global world. So, I do have the opportunity and privilege of talking to different business leaders across industry segments. The themes are resilience, technology, and sustainability, right?

Joel Solomon (11:06):

So, if I talk about the first one, resilience, and no doubt it’s a corporate buzzword, right? But if you strip away the hype around it, it becomes real. And I really like the definition of the word as per the dictionary, right? It says the capacity to withstand or recover quickly from difficulties. So, resilience is emerging as a vital muscle for companies to deal with endless volatility and disruption, right? So, we’ve had the pandemic where companies were expected to move much faster than before, become much more agile than before. And now we have in inflation which seems to linger around for a long time.

Joel Solomon (11:46):

And so, hence, how do you recover as a business? And this is one of the key themes in terms of resilience, right? How do you build a resilient business? And how should leaders go around looking at this aspect? Second aspect is technology, of course, right? So, you have technology that’s widely available. And this is true for exploiting any new business opportunity out there that you need to consider technology. It’s true for non-tech companies that are making the shift to put software at the heart of business. As much as it is true also for mature organizations that are trying to get maximum value from their digital transformation.

Joel Solomon (12:25):

So, technology is there, but how do you leverage it? And how do you employ it to give you the best bang for your buck, but also to get your organization to move ahead and become competitively much superior than your competition? So, that’s how technology comes into the theme of what’s on business leaders’ mind.

Joel Solomon (12:43):

And then the third, it is definitely one that is bandied around — all around the world in any conversation, sustainability, right? So, as much as it is, as fancy word that’s thrown around, it is become a core business topic of strategic relevance. And what does that do? It makes businesses look at your business in a completely different way than before, right?

Joel Solomon (13:08):

So, going into the be future, there’s two realities. One is you will have sustainable businesses, and the other is you have no businesses because it’s so important. And why is it important? Because our expectations as stakeholders, be it a consumer, be it an employee or investor or customers, we demand to work with sustainable businesses, right? So, that’s the trend. And people are getting more conscious in terms of what you buy. The shoes that I’m wearing is a hundred percent sustainable. And so, I make it a conscious effort to look at clothing or any of the stuff that I invest in or buy for my own use to think about, OK, is this come from the right source?

Joel Solomon (13:44):

And so, technology can be a great enabler and accelerator for us and the businesses to achieve these goals. So, these are the three key themes that I pick up on as I talk to customers around the world.

Scott Luton (13:55):

Wonderful. And you know, Allison, if Greg were here, he’d be talking about the power of the and, right? Resilience and technology and sustainability. You can get all three.

Scott Luton (14:05):

All right. Carsten, how about you? When it comes to what business leaders, what they’re prioritizing out there, what are your thoughts?

Carsten Wutzler (14:11):

Yes. Joel spoke also a bit about the business resiliency. And I want to add my view on supply chain resilience as a topic. So, we are doing regularly pulse checks with our clients about the supply chain, and they are still facing the disruption in their business in the early year. And more half of the year, it went a little bit well. They are experiencing still this disruption and then it’s clearly far from over, yes. And despite, there’s a trend of normalizing, now it’s shifting to one of disparity, of the rising prices and expenses. So, it’s a challenge for all companies, in terms of, revenues and profit.

Carsten Wutzler (14:51):

When it comes to technology, I want to a little bit push the spotlight to a smart query and operations. So, manufacturers still are progressing in this area, yes, because they see it as a source of future competitiveness. They’re investing in those technologies like Cloud, edge computing, 5G, and so on within the manufacturing space. And it’s really that they are applying things, and the leaders are bringing this technology also to their partners in the ecosystem.

Carsten Wutzler (15:19):

And the third topic I want to add is talent workforce. When I talk with my clients, they also have a long-term view on this. And they are a little bit worried about their workforce, the number of open positions. They are facing tight labor markets, workforce churn, and so on. So, it’s a change for them. And despite of the high level of new hires, job openings, and so on, it’s still a challenge. And, yes, this creates some limitations in the supply chain for sure, and reduces operational efficiency and margins.

Scott Luton (15:56):

Yes. Carsten creates some limitations, also is powering some opportunities and lots of innovation.

Scott Luton (16:01):

You know, Allison, when you think of the two to three that Carsten shared, rising prices and workforce concerns and challenges, any thoughts on your side, Allison?

Allison Giddens (16:11):

That’s — that common theme of resiliency, kind of, tying it all together. It’s been fascinating over the past few years to watch, almost the evolution of the supply chain or the maturation of the supply chain. It’s like we just — we have new problems. It’s not like it’s, you know, it’s the same problems, it’s new, but that key of resiliency spread across everything from the sustainability to the workforce. We have to learn that there are going to be problems every single day. It’s not a matter of avoiding the problem, it’s a matter of how are we going to address it.

Scott Luton (16:44):

Right. That’s right. Keep on coming. And as the great — the late Sandra McQuillan said, yes, there are finish lines, but they come with a starting line right in short order, right? Celebrate the wins, but there’s always more challenges to come. Nice — nicely said, Allison.

Scott Luton (17:02):

OK. So, we’re going to shift gears here, and we’re going to be talking about one of Joel’s, maybe Carsten too, a topic that I know is going to get Joel ready to dance like he’s listening to ABBA on that Walkman back in the late ’80s. So, the land — we’re going to be talking about the land of procurement. The wonderful world of procurement.

Scott Luton (17:19):

So, Carsten, let’s start with you then. We’re going to give Joel a chance to compile his thoughts. So, Carsten, when we think of some trends, issues right now that are really important in the procurement space to identify for our audience, what comes to mind, Carsten?

Carsten Wutzler (17:34):

The first one I see is really the increasing criticality of procurement. So, the CPOs reported a high inflation pressure as their number one risk to the organization, and they are the forefront of fighting this topic. They still have the cost pressures, the saving captures, and driving more value over their — the full life cycle of the cost and goods services. So, this is the evergreens in procurement. So — and the landscape of the CPO is really extending because now you have also these geopolitical forces that it makes it more complex.

Carsten Wutzler (18:09):

In Germany, I heard the word of friendshoring, which refers to the region that suppliers are based and politically aligned with the company’s home country in terms. So, security supplier is also hot topic, and to log and really the supply from the trusted supply partners you have in your network.

Carsten Wutzler (18:26):

The second one is really need for orchestration. It’s not just one priority in procurement, it’s also the procurement operating model, investment in talent, turbocharging, the digital transformation, and to remain really agile and efficient over the years to come. And this is a balance between the traditional cost focus you have and other emerging topics.

Carsten Wutzler (18:52):

And I would add also this sustainability and corporate social responsibility to this. It’s a good point to mention. It’s significantly getting important. So, 90% of the clients they see, really, that customers are seeking, where to spend money that is really aligned with their values. Companies need to embrace the challenge to the pathway to a net zero, or to a circular economy to really avoid the competitive disadvantage that might result from being not part of the journey or being engaged as others.

Scott Luton (19:28):

So, Carsten, I want to go back to an earlier point you made about orchestration before I come to you, Joel. And Allison, I’ll get your take. I’m not sure what it is, but, you know, there’s a little — I don’t want to say stick, but there’s a little device that a maestro has for a symphony, right? I’m not sure what those are called.

Scott Luton (19:42):

Allison, you’re smiling. Maybe you can tell me what it is. But it’s almost like whatever that thing is called, that supply chain practitioners as they come in, that’s one of the things they’re given as they embrace the role of orchestration, as Carsten’s become one of our favorite words around here. Allison, your quick comment before we move to Joel and get to his take on what’s going on in the world of procurement.

Allison Giddens (20:04):

Yes. No, I agree. I’m seeing it on the end of being a manufacturer, for sure. It’s — it is about — I mean, in the micro world of things, I’m dealing with parts that have to be sent to an outside processor, but before we send them to one, it has to go to a certain other one. But in order for that, the second person to have them, then they have to be well aware of what happened to the first batch of processes. So, there’s all these things that we, I think, have taken for granted for so long. That we’re starting to realize now that, wow, if everybody is on the same page, life goes a lot easier. So, I think there’s that orchestration, like you said, that’s been key to a lot of the success.

Scott Luton (20:45):

So, Joel. I’m told an excellent comment — sorry, Allison. I’m told by Donna, Catherine, and Amanda behind the scenes, helping to make production happen. Thank you very much. That a conductor stick is a baton, is what I’m thinking of, Joel. So, I’m learning something new every day. But it paints such a perfect supply chain image in my mind.

Scott Luton (21:04):

But, Joel, commenting on that, what Carsten said, what Allison said, or tell us about some of the things you’re identifying in the wide world of procurement that more members of our audience need to know about.

Joel Solomon (21:14):

It’s funny you mentioned baton in supply chain in the same rep, because baton is also used at the relay, right? So, when you run relays, you exchange the baton, and that’s the link to the supply chain going, you know, seamlessly. So, there you go, baton can be used in more than one way and fits aptly with supply chain. Maybe you should have a logo called, Baton, as part of your Supply Chain Now or something.

Allison Giddens (21:37):

Yes. Let’s — can we — yes, let’s trademark that, four of us. Let’s go in on that.

Scott Luton (21:40):

Yes, listeners, audience members, that’s ours. You can’t take that. You can’t take that. Joel, lots of brilliance there.

Joel Solomon (21:47):

Yes.

Scott Luton (21:47):

All right. Cool. Please continue.

Joel Solomon (21:48):

Thank you. Coming back to what’s happening in the land of procurement. And I know Carsten touched on some high-level strategic focus of procurement leaders. I’m going to, kind of, bring it down a notch to operational excellence, right? So, what we are seeing happening in procurement landscape, currently, is four key themes. One is driving supply performance and taking the partnership to the next level. Second is category management. Third is becoming more customer centric as a procurement organization. And fourth is sustainability within the scope of procurement.

Joel Solomon (22:21):

So, when I say drive supplier performance and take partnership to the next level. So, this is absolutely important, critical, right? So, when — since I’ve been a buyer, I’ve always believed that a supply is not just an external party providing goods and services, they are absolutely core to your success. I’ve lived that. And when I’ve had teams, I’ve always told my buyers, treat them with respect. Treat them as a peer because your — their success is your success. And you’re intricately linked with each other.

Joel Solomon (22:52):

So, important thing is, driving suppliers and holding them accountable to the next level of delivery of whatever that is that you’ve committed with each other, but also taking the partnership to the next level. So, which means treating them as peers and investing in them, and making sure that they understand it’s not just a power treatment where the buyer comes and beats the supplier, but it is actually a win-win for both parties.

Joel Solomon (23:16):

When I was working for Honda, Scott, so we have this beautiful concept that we were trained on. It was called Gemba, right? So, Gemba means an actual place of work where work happens. So, we would go out and visit the supplier locations to actually see how they doing, what is infrastructure like, what’s the management like? So, you have real feeding and connection with the supplier. So, this is something that I’ve carried on and that I practice. And also impart every given opportunity saying, know your supplier, that’s the best way of having the best supply experience.

Joel Solomon (23:47):

But coming down to category management, category management has existed for several decades now in one form or another, right? So, we spent — organizations typically spend tons of money with consultants to come and tell them exactly what they know, and they leave them with a deck, with a PowerPoint that typically sits in a drawer somewhere or put in some shared folder somewhere to be forgotten. But to be taken out during annual review saying, look what I’ve done. It’s an amazing piece of paper.

Joel Solomon (24:14):

But today we have technology. So, you don’t have to have this category plan strategies on a piece of paper or on a deck, but you can actually deploy it onto a platform with the help of software and use it on an operational basis. So, for example, the category strategies, the innovators and the triggers for the category, or the savings or targets that you’ve set can actually be operationalized in the system. So, this is where buying organizations and supplies can take a lot of leverage and benefit from the category management.

Joel Solomon (24:44):

Third is customer centric. Procurement organizations have to become customer centric in order to serve your own stakeholders internally within your organization at a much superior level. And the reason for that is, today we all have thousand different apps that we go to and we buy services and goods. It’s so seamless, so intuitive, at the click of a button you have your service. When we come into organizations, the end user expects the same thing of procurement organization saying, give me a tool. Give me a platform that’s easy, intuitive, attractive enough for me to use. So, that is becoming a huge topic where procurement has to really deliver a customer-centric experience for their own internal stakeholders and their suppliers.

Joel Solomon (25:27):

Finally, sustainability. Sustainability, when you drill it down and start capturing sustainable — sustainability fields or data in a specific way, each organization has their own different ways, and everybody’s struggling. We had an automotive round table in Waldorf last month, and we had some of the biggest names in automotive turn up in Waldorf and we had a two-and-a-half-day workshop. One topic was sustainability. Everybody wants to capture sustainability data so they can improve their supply chain and look at green initiatives, but they don’t know where to start. It’s too big, too complex.

Joel Solomon (26:01):

So, one of the key things is use technology to start small. Start somewhere so you can then start expanding as you learn, as you grow, and then you can have a really good roadmap for you to capture your sustainability data. So, these are some of the key themes that is relevant in procurement these days.

Scott Luton (26:18):

Yes. Well said, Joel and Carsten.

Scott Luton (26:21):

Allison, I want to come back to something that Joel said about halfway through his last response. In the Gemba. Going to the Gemba, right? Where that value is created, you know, all the leaders that we have, you know, interviewed now, you know, approaching I think 1,300 episodes. Whether it’s in retail, where you’re going to where your store associates are and learning what they see on their — right there on the frontline, or if it’s a manufacturing site. You’re going where folks, you know, where things are being made. That’s where some of the best innovative growth ideas come from. Allison, your quick comment there.

Allison Giddens (26:53):

I think it all ties back to what Carsten talked about earlier with the workforce challenges. I think that if we can hone in and really make the most out of the opportunities that we see within Gemba, then we are, therefore, fostering our current workforce. We’re retaining employees, we’re attracting people to come work for us. Because especially with this next generation, the next two generations entering into the workplace, they’re not driven by the same things that we all were.

Allison Giddens (27:23):

And these next generations, they’re driven by sustainability. What are we doing for the planet? What are we doing for the next generations after them? They’re driven by, what is my work today? Why does it matter? Why would I work eight to 10 hours to go home, cook dinner, fall asleep, and do it all over again? Like, they want meaning. They want — and I think that is — those are key places to find this.

Scott Luton (27:46):

Beautiful, Allison. Love that. And also, I liked how Joel mentioned that using technology to find that simple starting point, right? Get that done and then you can layer on that. That, to me, that is a more purposeful application of technology, right? Rather than just getting the latest and greatest and throwing the defense to the team and doing it — doing things to your people rather than with them.

Allison Giddens (28:09):

Yes. And — well, and there’s psychology behind that too, with those little wins. I mean, that’s how you keep motivation goings is, you have many goals, and you have these many, many KPIs that you can say, OK, we did this. Now, let’s see what happens when we do this.

Scott Luton (28:23):

Yes. OK. Allison, Carsten, and Joel, we’re going to — we’re about to walk through four more specific opportunities. But before we do, I want to share just a couple of quick comments. So, my man, Allen Jock [phonetic] had — I was going to save me, in addition to everyone else, with the baton, right? The, instrument that the maestro uses to conduct the orchestra.

Allison Giddens (28:45):

Also known as our new company, the four of us.

Scott Luton (28:48):

That’s right. That’s right. We have attorneys waiting to help us with incorporation after the show. Kaya is a big fan of the Gemba as well. I think many of us are, right? Now, Jerry says — maybe we have time to touch on this later, but Jerry talks about how procurement groups use soft criteria, meaning reputation, flexibility, history, when making decisions on procurement. Because as he adds, things that are important, but can be hard to put empirical data on. That’s a great comment there, Jerry.

Scott Luton (29:16):

All right. So, Joel and Carsten, I think a lot of — you know, a lot of — we’re halfway through the show. A lot of this has been good news, at least to my ears, right? But there’s more, right? Faster, cheaper, better. We’re going to be picking your brains on four specific opportunities when it comes to what you’re seeing out there and what’s the art of the possible, the really real tangible art of the possible.

Scott Luton (29:37):

So, Joel, I’m going to start with you. Let’s talk about optimized product lunches — launches. I keep wanting to say, product lunches. I’m not sure what that is, but I need to tweak that.

Allison Giddens (29:45):

Are you hungry, Scott? Are you hungry?

Scott Luton (29:47):

That must be it, Allison. That must be it.

Scott Luton (29:50):

Optimize product launches and ongoing procurement of highly engineered parts. So, Joel, tell us more.

Joel Solomon (29:56):

Yes. So, this is an absolutely interesting and fascinating topic, Scott, and particularly relevant to automotive and IM&C industries. Think of, you know, an automotive company launching new products, new cars, or new trucks, or whatever they are, or IM&C industries like launching a new washing machine, for example, right, different models of it over the next few years.

Joel Solomon (30:18):

So, this is again, I mean, where the genesis of this came from in terms of the procurement planning, what we call is procurement planning for product launches, new product launches, this is a great story of co-innovation with our customer. SAP didn’t think of this solution from where we stood, right, because, far away, we’re not necessarily close to every single action that happens at customers. But when customers open up their doors and explain to us their business process and tell us, hey, there is a gap, especially where we have a huge high level project planning for new vehicle launches. And out of this high-level project planning, which happens at an organizational level, then comes the procurement activity where you have to start sourcing and collaborating with engineering and planning and logistics and quality to go and source parts from the outside, there was a gap in terms of the planning.

Joel Solomon (30:52):

So, effectively that gap was being filled out or bridged by manual documentation, tons and tons of Excel spreadsheet, SharePoint decks, and all kinds of things. So, Volkswagen said, would you be able to kind of, you know, help us bridge the gap between the overall organizational planning and the procurement plan? So, SAP invested a lot of time with Volkswagen in terms of creating this beautiful solution, which we call procurement planning which ties into the organizational planning level for new product launches.

Joel Solomon (31:37):

So, it helps both the project teams that comprises of buyers, engineers, logistics, quality, finance, and controlling everybody to come together, understand the project through the same lens, and then break it down in terms of the engineering bill of material that we have. Break down the bill of material completely at a part level, and then plan for activities at a part level in terms of sourcing. So, what happens is there’s a continuous flow from your organizational planning, to your procurement planning, and then to sourcing. And then it goes across until you’ve sourced the part, selected the supplier, and then you start consuming the part. And there’s also feedback mechanism in terms of information flow backwards and forwards, which means there’s a constant set of transparency that is built into the platform and single data flow that is connected end to end.

Joel Solomon (32:30):

So, all party — parties that are involved in a project have the same information, and a decision can be made really, really quick in a timely fashion, eliminating a lot of waste. So, this is where — this particular feature has come in, in terms of planning around new product launches and helps the engineering changes and to control it better and manage it better.

Scott Luton (32:52):

Yes. Joel, and not only enabling fast decision making, but good effective optimize decision making in addition. Now, I’d also add that gap in the planning that you spoke about, right? Folks using lots of spreadsheets, they’re using duct tape, band-aids, whatever it took to bridge that gap. And there is a better, certainly a better way.

Scott Luton (33:13):

All right. Let’s switch gears. Carsten, I want to talk about something that we’ve touched on quite a bit in the first half of the show here today. Supplier collaboration that truly fuels innovation. Carsten, tell us more.

Carsten Wutzler (33:24):

Yes. So, supply chain management, and in specific, the supplier management is a well-established practice. That’s all organizations seek to extract most of their commercial relationships. And when well-done effective sourcing and negotiation and this contract management are really part — core tools in your procurement toolkit.

Carsten Wutzler (33:45):

When it comes to deepening supplier relationships and increasing collaboration, those are the both teams that CPOs worry about. It’s a top strategy to really deliver the most of the value. And across 40 countries, they are saying it. So, really, it’s a high visibility on board level when you talk to the leaders in procurement. And it’s no surprise because, it’s a critical for assurance of the supply, given the recent disruptions. And for those that are not prioritizing, it might want to think about twice before doing it in an improper way.

Carsten Wutzler (34:19):

And when you move up the maturity curve of an organization, you see some increased level of sophistication now to bring more parties involved and more suppliers together, and then make it really part of the strategy. And industry leaders, for example, they have been successful in piloting and expanding applications for a digital collaboration between those parties. Like, for example, SAP supplier quotation management, which is a self-service portal where your ERPs, you can hand in your quotes, you can upload your documents like certificates or whatever you feel that is necessary within the sourcing. And also, really bring in some innovative ideas so that you have this interaction with your suppliers.

Carsten Wutzler (35:03):

And there’s also the level beyond this, like the innovation hub and the processes you need to really bring ideas to your company and into real life, and this is the key thing in supplier collaboration. And of course, it goes to sustainability, ESG focus, collaboration, really, that you start using scope three emissions in your supply chain. And from my perspective, all those collaborations should be built on a win-win mindset that brings rewards for all parties, and technology is really an enabler for this. And if the suppliers are bringing innovative ideas to you, you are doing it right. That’s my perspective.

Scott Luton (35:43):

Yes. Carsten, a lot of goodness. And Allison, I’m going to get you weigh in here. But a couple of things I want to call out of Carsten’s answer is that digital collaboration, it’s become table stakes, right? And it’s helped — you know, one of the things that has emerged from the pandemic, for sure, is you’ve got to be a good customer these days, right? Suppliers have more and more choices in how we leverage digital platforms, in how we baked that into our digital transformation allows us to be a much better customer in creating truly the win, win, win scenarios rather than the cliche version of that that Carsten and Joel both have been touting in value of.

Scott Luton (36:17):

Allison, speak to working with your suppliers.

Allison Giddens (36:19):

Yes. No, that makes a heck of a lot of sense. There’s — we had a customer recently come to us and ask us for our opinion on something. And I was floored because this particular customer is a very large customer and they don’t really need my tiny little company. I mean, if they decided tomorrow, they could go somewhere else, they could. And they asked for our opinion on something, and it was something that has really been a piece of the grief in the supply chain, the manufacturing process.

Allison Giddens (36:46):

And so, I found myself sitting down and spending many hours on feedback and turning around and saying to them, hey, I’m happy to volunteer my time further to have more of a conversation and help come up with ways to fix this. And it was funny because the unintended consequence was now, they wanted to work with us more because we were open to wanting to help them with their process, recognizing it was going to ultimately benefit us to make our lives a little easier.

Allison Giddens (37:17):

So, I think this the collaboration piece, if we can all work together on the stuff that used to be really complicated and streamline that, then it opens ourselves up to be able to do new hard stuff and really set ourselves apart.

Scott Luton (37:32):

Yes, Allison. And one of the things I heard there is time, it’s long past time to have different conversations with your suppliers and customers because if they’re unaware — if left hand is unaware of what the right hand is great at, or struggles at, or whatever, there’s great wins there to be had for the whole ecosystem.

Allison Giddens (37:49):

There you go.

Scott Luton (37:50):

All right. So, I want to share a quick comment here from Sylvia Judy [phonetic]. Great to see you, Sylvia. Supply chain management is definitely a high priority in any organization that wants to sustain. I’ll add, endure, win, succeed, you name it. Absolutely. And Sylvia safe travels to wherever you are in your journey.

Scott Luton (38:10):

OK. Joel, getting back to you. Let’s talk about better material costs management. Tell us more, Joel.

Joel Solomon (38:17):

Yes. This is a really interesting topic for procurement folk and for organizations, right? So, when you associate cost management, you automatically think of driving down costs. And I’m — I firmly believe that it is not about driving aggressive competition with your suppliers or twisting the arm of a supplier to reduce your cost. I suppose it should be a new way of doing things. It’s about using data intelligence and transparency to remove waste, to make timely decisions and become more effective and efficient in utilizing the resources and technology available to you to achieve a better approach to cost management, right?

Joel Solomon (38:56):

So, think about manufacturing organizations, there’s deeper supplier collaborations that is necessary. We’ve been talking so much about how do you bring in suppliers? And we also had a comment from one of the audience members saying, what about the softer features of treating suppliers with respect, and then actually engaging them in conversations and then giving them the time and place to input and contribute to ideas?

Joel Solomon (39:20):

So, that partnership is absolutely key for you to get a really good outcome to cost management and keeping all parties happy. And it is also important to understand, you know, procurement intersects with different organizations. They work with engineering, work with planning, work with logistics and manufacturing.

Joel Solomon (39:37):

So, it’s the — it’s about the end-to-end approach. It’s not just one dimensional of reducing cost via sourcing activity or running an RFP or a tender [phonetic]. It is about the connectedness of it, working with all the different stakeholders, and then coming up with the best outcome that, in the end, becomes a win-win. So your suppliers are happy and you’re happy as an organization, and you can both be successful together.

Scott Luton (40:00):

I love that. And, Joel, that perfectly — I like John Peterson’s comment here, supply chains are becoming more collaborative versus adversarial. I agree, John. I agree. And I also believe that digital collaboration and how we engage technology in a very practical, powerful, purposeful way helps enable this shift, massive shift that’s taking place.

Scott Luton (40:23):

Allison, comment on what we heard there from Joel.

Allison Giddens (40:26):

Yes, that makes a lot of sense. A lot of that, the — there are a lot of old standards or old ways of doing things that, I think, it’s been hard to get out of. So, for example, in aerospace work in AS9100 and ISO quality management system standardization and certifications, there’s a requirement that requires you to basically send scorecards to your suppliers, and to rate them, and to manage the risk and all of this. And in the old way of doing things, it used to be very, you know, in your mind’s eye you could say, OK, well you were late half the time, so I’m going to give you a 50%. And, you know, your quality was this and your quality — and I found that when we would do those things, all we would do is make enemies. All we would do is make it so these people didn’t want to do business with us.

Allison Giddens (41:12):

And so, I think by thinking different ways of, yes, you can still do things by the book. You can still have your standards and score and manage the risk like you’re supposed to within your supply chain. But instead of just carte blanche making a 50% score, talk about the relationship itself with that supplier. Talk about the, you know, OK, well, we’re going to add to, I think to somebody’s point, it’s hard to score kind of your, subjective things rather than your objective KPIs. Think about the relationship itself and figure out ways to score that. Maybe that 50% is now a 90, or maybe it’s a — maybe there’s no percentage. Maybe there’s a, hey, looks like we need to improve on the delivery time. But man, this supplier is great to work with because they always answer the phone, you know. And make those kinds of comments, that — the supplier relationship piece, I think, cannot be understated.

Scott Luton (42:01):

Yes. More holistic is one of the things I’m hearing from you as well.

Joel Solomon (42:04):

Hey, Scott. Can I just comment on the previous comment that you flashed up on the screen where you said supply chains are becoming more collaborative rather than adversarial? I would take it a step forward. Thanks, John, for that observation. I would’ve been — taken this a step forward and say, even competitors are becoming more collaborative rather than adversarial.

Joel Solomon (42:22):

So, when we had this automotive round table in Waldorf last month, like I mentioned, we had the likes of BMW and Mercedes, Ford and Volvo cars stand around the table in front of a whiteboard talking about their business processes and challenges. That was absolutely mind blowing and powerful, right? So, of course, there’s a sense of confidentiality that goes into such conversations, but for them to open up and discuss the challenges together, to build a potential outcome and solution together that could satisfy all their needs is just brilliant. And this is where the world is moving, where it’s more about collaboration rather than adversarial and trying to get a leg up.

Scott Luton (43:00):

So, Joel, I love that perspective. And who knows, maybe the call of wars will be over soon as well. Get everyone — all those folks around a table, that might be a bridge too far. I don’t know.

Scott Luton (43:10):

All right. So, why don’t we have one last? I promised four specific opportunities, right, where there is a better way. Carsten, you get the last one. You’re cleaning up pitter here. We’re talking about leveraging ERP to gain more supply chain flexibility. Carsten, tell us more.

Carsten Wutzler (43:26):

Yes. So, in order to achieve more supply chain flexibility, companies need to really revisit their supplier segments and ensure that they align with these traditional measures of contract spend, volume, complexity. As well as, have a complete view on the business criticality and risk exposure of their partners. Procurement teams need to identify where supply chain redundancy must be built into these operations and on demand fluctuation or supplier risk, what they have. And the reliance on single sources for their critical inputs must be minimized, and therefore supplier base needs diversification to get ahead of those potential bottlenecks.

Carsten Wutzler (44:08):

And this is where technology and ERPs kick in. So, they are digital backbone of the processes of the capabilities like sourcing execution, purchasing and compliance, supplier collaboration, intelligence and analytics. Systems must be set up that those sourcing can be started quickly once those supply chain challenges become visible. The buyers, they expect that the data they have, like supplier lists, demand figures, pricing conditions, are really put into the sourcing on a click of a button. And those systems need to handle what we call supply chain flexibility.

Carsten Wutzler (44:44):

For example, if you’re running competitive sourcing and you’re following a dual sourcing strategy, the ERP systems must handle this quotation and the quota behind between those suppliers and transfer to purchase orders or contracts at all. And the whole process needs to be supported by strong automation and integration capabilities.

Carsten Wutzler (45:05):

Another part I’d like to mention is the transparency on supply chain data that really sits into this ERP systems. This is the basis for, let’s call it, the supply chain control tower where you can steer your supply chain and understand really on a very operational level what is going on in terms of supply chain flexibility. And modern supply chains, they’ve become more complex, multi-tiered, increasing reliant networks, third party risk incidents, they can really — they doubled over the last five years, so to say. And really have — having showed that this single isolated problem can bring a global supply chain to a halt is really frustrating, so to say. And that’s why you need technology as really a backbone for this.

Carsten Wutzler (45:50):

And as a summary, I would say procurement and the technology is really a competitive advantage. The future will be smarter, more agile, more tech enabled. One that eliminates non-value activities and make decisions more fact-based and faster.

Scott Luton (46:08):

Carsten, I like the pick — the future that you paint. I got a little Picasso going there. And it’s — technology is inseparable from that, right? One of the elements you added.

Scott Luton (46:18):

All right. So, for the sake of time, and by the way, folks, we’ve got Carsten and Joel, they’re in the great Detroit, what a great American city as they’re engaging and talking with members of the automotive industry. So, you may notice that we’re going to get quite — we’re going to get the highlights of the Joel and Carsten Road show, that’s going to be the next episode here at Supply Chain Now, perhaps.

Scott Luton (46:40):

But Joel, as we start to wind down, come down the home stretch of today’s show. I want to pose an interesting question to you. So, when should business leaders reach out to SAP, not just to learn more, but maybe to do more? Joel, your thoughts?

Joel Solomon (46:55):

Yes, Scott. I mean, look, SAP is known as the most advanced ERP software organization in the world, right? So, that’s just the core of who we are. But we have so many different line of business solutions that plug and play with the core, the heart of the ERP like procurement and supply chain, human capital management. And you have analytics and digital boardroom. And you have digital supply chain and the likes of it.

Joel Solomon (47:23):

So, in terms of SAP, we’re here to talk to our customers, to understand what their challenges are, and how they need help or information, right, or education, whatever the case is. And especially when we drill it down and talk about the area that I’m currently operating in, in terms of automotive and IM&C procurement solutions. We’ve launched this SAP product sourcing suite, and we have a link that we can share with the customers as well. And then this is something — it’s a video, the customers can go through it. And if it is helpful, we’re open to having conversations and coming and talking to you. We’d be most glad and grateful for the opportunity to engage with the customer base.

Scott Luton (48:00):

And I can tell you all, you will enjoy it. I’ve enjoyed the pre-shared conversations. I’ve enjoyed this conversation with Joel and Carsten, and always, Allison, that goes without saying. So, and he — so, Joel, mentioned a video. So, Joel and the SAP team have brought a really neat resource to the table, a brief video, as he mentioned, that illustrates SAP’s product sourcing solutions. So, you all can check that out. See, we’ve got a link in the cheap seats in the gallery, in the VIP lounge, I think, is Allison, the word you coined there. You’re one click away from checking that out.

Scott Luton (48:32):

And I want to add, Rotnesh [phonetic] adds a great comment here. It’s all about visibility, collaboration platforms, capturing every supply chain event and making it visible to get back to that faster, better decision making that Joel, Carsten, and Allison all have spoken to here today.

Scott Luton (48:51):

OK. So, Allison, I am going to get your key takeaway here today. But before we do that, I know everybody’s — it’s a busy — what is today? It’s a busy Tuesday on everybody’s schedule here today, right? But we want to — we’d be remiss if we didn’t make sure folks knew how to do just that. Reach out to Joel, have those conversations for that matter. Reach out to Carsten, have those conversations.

Scott Luton (49:13):

So, Joel Solomon, senior director, Strategic Customers with SAP. How can members of our esteemed audience connect with you?

Joel Solomon (49:19):

Scott, of course, LinkedIn is the most preferred way, but I’ve also dropped in my e-mail address on the chat box so we can make it available to the participants as well. More than happy to have conversations and answer any questions that the participants have.

Scott Luton (49:34):

OK. Fearless.

Joel Solomon (49:35):

And more importantly, learn from our participants as well, right? So, I’m sure they have amazing stories and experiences and it’ll be absolutely fantastic to learn from them.

Scott Luton (49:43):

So, as you all see there, Joel is fearless. So, the e-mail is out there. You can also connect with Joel on LinkedIn. And hey, Ms. Peter. Yes, the whole presentation, today’s presentation will be available both on social, the video presentation, and the audio podcast will be dropped in supply chain of podcast channels in the coming days.

Scott Luton (50:05):

All right. So, Carsten, you brought a truckload, maybe a couple truckloads of brilliance here today. How can folks connect with — let’s say, Carsten Wutzler, Director, Enterprise Performance with Deloitte, how can folks connect with you?

Carsten Wutzler (50:18):

Yes, for sure. Also, via LinkedIn, that is a preferred way of communication. You — I hope you will find me easily when you enter my name. And for sure, there’s also business e-mail attached to, and you can write me on our Deloitte mail. So, happy to receive further questions and inquiries.

Scott Luton (50:35):

I like how both you all keep it easy. We need more — Allison, I think this came on our last conversation. We need more easy buttons in supply chain. None of it’s simple, but the better we can at keeping things simple and focused, the better we all are in the more progress.

Allison Giddens (50:50):

Leave it to the engineers with the business backgrounds to streamline it.

Scott Luton (50:56):

Most stuff, Allison. Most stuff. All right. So, Allison, right on time. So, we really enjoyed this conversation with Joel and Carsten. But Allison, what is one — I’ve got my 17 pages of notes, but what is one key takeaway that our audience has to lead this conversation front of mind?

Allison Giddens (51:13):

OK. So, I’m going literary here. John Donne, the author that “No Man Is an Island”, home. I’m thinking that no link in the supply chain is an island. And that’s kind of where we’re at. I mean, that’s all that the topics today surrounded around resiliency and collaboration and transparency and visibility. And the fact that you can’t operate in a silo anymore and be successful. I mean, you can operate in a silo, you’ll go out of business in a week. But I think the key here is, yes, you can’t be alone in it all anymore. Even — whether or not you — if you like people or if you don’t, you’re going to have to work with them. So as manufacturers, as supply chain, wherever you are in the link, you can’t do it alone. Period.

Scott Luton (51:58):

That is right. And especially if you want to grow, succeed, innovate, do it better, provide more opportunities across the ecosystem where truly everyone can win. Hey, reach out to great partners. All right. So, with that said, I want to thank again, Joel Solomon with SAP. Joel, thanks for joining us here today.

Joel Solomon (52:17):

Thank you, Scott. Pleasure being here.

Scott Luton (52:19):

Definitely. And Carsten Wutzler with Deloitte. Thanks so much for joining us, Carsten.

Carsten Wutzler (52:24):

Thanks, also a pleasure from my side. Happy to be here.

Scott Luton (52:27):

You all have a wonderful trip in Detroit. Allison, thanks all — for always being a part of these conversations. Thank you, Allison.

Allison Giddens (52:33):

Absolutely. Great to meet you both and great conversation.

Scott Luton (52:37):

Here’s the thing though, folks, you have plenty of choices out there. One choice is a take action or not take action, right? I would encourage, hey, deed’s, not words. Put it in a football and run with it. There’s a better, better way. So, with that said, on behalf of our entire team here at Supply Chain Now, Scott Lutton challenging you, do good, give forward, be the change, and we’ll see you next time right back here at Supply Chain Now. Thanks everybody.

Intro/Outro (53:02):

Thanks for being a part of our Supply Chain Now community. Check out all of our programming at supplychainnow.com and make sure you subscribe to Supply Chain Now anywhere you listen to podcasts. And follow us on Facebook, LinkedIn, Twitter, and Instagram. See you next time on Supply Chain Now.

Featured Guests

Joel Solomon is a Senior Director within SAP’s Global Centre of Excellence for Procurement. He is a former procurement practitioner and focuses on supporting Automotive and Complex manufacturing Industries in their quest for technology-led procurement transformations. His expertise includes direct & indirect procurement and digitalization of processes and establishing business value. Connect with Joel on LinkedIn.

Carsten Wutzler is a Director within Deloitte’s Sourcing & Procurement practice in Germany. He focuses on business-led transformations with S/4HANA and his expertise includes sourcing of direct materials, digitalization of processes and procurement technology in general. Connect with Carsten on LinkedIn.