Intro/Outro (00:00:03):

Welcome to Supply Chain Now, the voice of global supply chain. Supply Chain Now focuses on the best in the business for our worldwide audience, the people, the technologies, the best practices, and today’s critical issues, the challenges, and opportunities. Stay tuned to hear from those making global business happen right here on Supply Chain Now.

Scott Luton (00:00:33):

Hey. Hey. Good morning. Scott Luton and Karin Bursa here with you on Supply Chain Now. Welcome to today’s livestream. Karin, how are we doing?

Karin Bursa (00:00:41):

We’re doing great today. It’s a beautiful day here in the Atlanta area. So, it really puts me in a good mood.

Scott Luton (00:00:45):

It is a beautiful day. We’ve got some beautiful TEKTOK digital supply chain orange working in our branding, which we love. We love what Karin Bursa is up to on TEKTOK. And, Karin, we’ve got an outstanding conversation teed up here today, as you know, with a couple of titans of technology. Now, Karin, we’re going to say hello to a few folks. We got a couple programming notes all before we bring in our speakers. But I got a couple of diginotes I want to share with you. Are you ready?

Karin Bursa (00:01:14):

Okay. Let’s hear it. Yeah.

Scott Luton (00:01:15):

All right. So, the first one, you may know a lot more about this than I do, Bruce Jay Nelson was born on this day back in 1952. Evidently he was a famed computer scientist. Best known – get this – as the inventor of the remote procedure call. I guess it has something to do with computer network communications. Do you know this?

Karin Bursa (00:01:37):

RPC. Yeah. Absolutely.

Scott Luton (00:01:39):

I knew it. You’re always a couple of intellectual rungs above me, so I figured that you’d get that one, assess Bruce Jay Nelson. Now, I’m little familiar with this, on January 19th, 1983, the Apple Lisa is announced. And if you remember this, it’s the first commercial personal computer from Apple to have two main things, the GUI, that Graphical User Interface, and something they call the mouse. How about that?

Karin Bursa (00:02:09):

Interesting. I didn’t remember that the mouse was associated with Lisa. And, honestly, I haven’t thought about the Lisa release in decades. But did you see anything why did they name it Lisa? Was there a reason?

Scott Luton (00:02:21):

Oh, man. I’m going to have to dive into that. In fact, this could be fodder for this weekend business history, so I’ll dive into that. One final note and then we’re going to get closer to the subject of the day. So, on January 19th, 1999, the Blackberry is introduced, later aka known as?

Karin Bursa (00:02:41):

The CrackBerry.

Scott Luton (00:02:42):

Yes. Right. Because everybody was addicted to their –

Karin Bursa (00:02:45):

I am one of those. Yeah. I was really upset when my phone upgrade moved from Blackberry to, you know, a regular device that we use today. But I liked that little ball in the middle and I could pound away on that actual physical keyboard that came with it.

Scott Luton (00:03:03):

I love that. And, really, ask and you shall receive, our cracker jack production team. Big thanks to Amanda, Shantel, Catherine, and Clay. They tell me that the Apple Lisa came from Steve Jobs’ daughter’s name. [Inaudible].

Karin Bursa (00:03:17):

There you. Okay.

Scott Luton (00:03:20):

All right. So, having a little fun this morning and we see you Seema, and Tom Valentine, and others, we’re going to say hello in just a minute. But, hey, Karin, I’ve got one more question for you. Have you ever had someone say, “I’ve got some good news and I’ve got some bad news, which one would you like first?”

Karin Bursa (00:03:37):

I have. I have indeed. And I think it’s so interesting to hear people’s response on this. So, let’s see what our Supply Team Now audience has to say first. I mean, Tom Valentine has always got an opinion. So, Tom, is it good news or bad news? Which one do you want to hear first?

Scott Luton (00:03:55):

Let us hear from you, folks. What do you want to hear first, good news or bad news? But, Karin, what else comes to mind when you think of those two options, those binary options?

Karin Bursa (00:04:06):

What do I think of? I immediately go to what I want to hear first and what am I going to do about it. Scott, which one do you prefer, good news or bad news?

Scott Luton (00:04:16):

So, I’m a sucker for good news. I like to have my good news first, so I can process the bad news a little bit easier. How about you?

Karin Bursa (00:04:25):

Okay. All right. I almost always like the bad news first. Because the good news, to me, is kind of dampened a little bit when I know bad news is coming. So, I just want to hear it. I rip the Band Aid off, give it to me straight. And then, I’ll start, you know, thinking about what can we do about the bad news, how do we solve that problem.

Scott Luton (00:04:46):

Well, the votes are coming in. Let’s see here. The production team says bad news first. Joseph says good news. Siemens says good news. Let’s see here, David says good news. Tom says, “Always have to address both, but start with the bad and always end on the positive.” Tevon with FedEx – our dear friend – “Avoid the news all together.” You can see more of Tevon Taylor in Vegas at the Reverse Logistics Association Conference. Okay.

Scott Luton (00:05:19):

So, today’s conversation, though – and we’re going to say a few more folks here in a second – is going to kind of be that good news, bad news, or uncertainty about supply chain, right?

Karin Bursa (00:05:30):

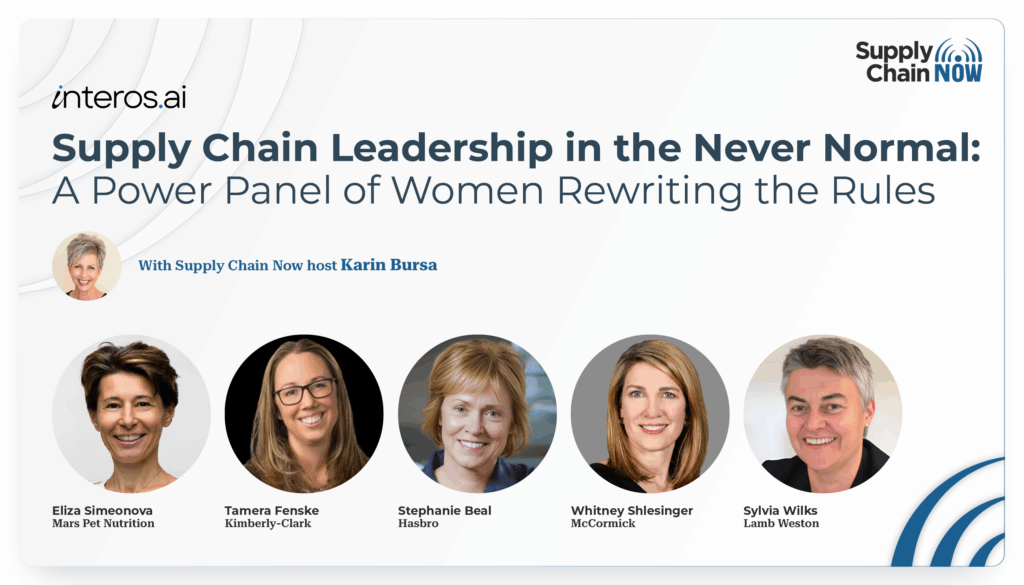

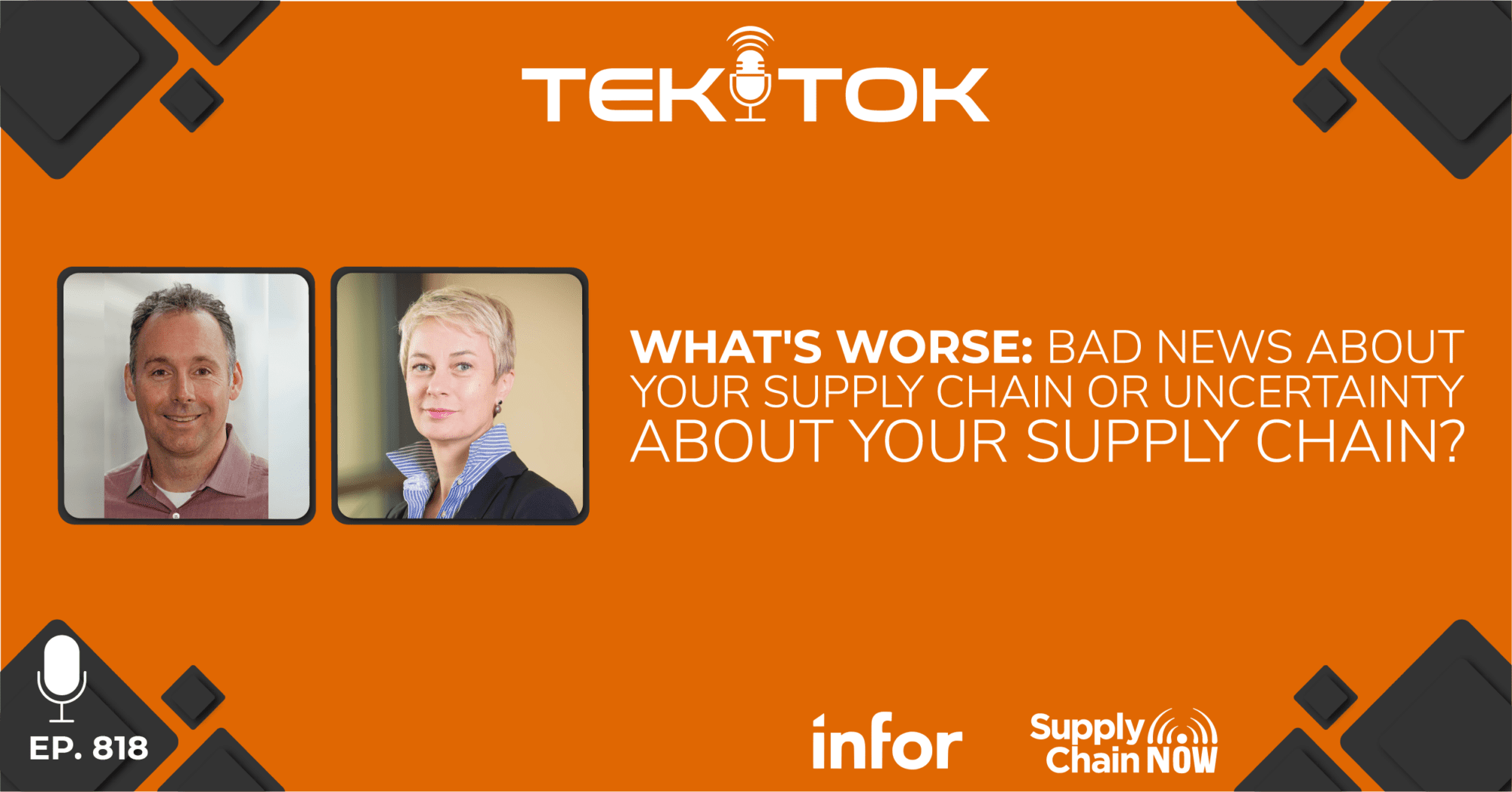

Yeah. It’s a really interesting topic. I like the way it’s posed, because we are going to talk about, you know, what do you want to hear first or what’s worse. Do I want to hear bad news about my supply chain? Or do I prefer uncertainty about my supply chain? And with us today are really, as you called them, two titans in the supply chain technology industry. We’ve got Monica Truelsch and John Nadvornik with us, they’re both with Infor, and they’re going to give us their perspective. In fact, guys, behind the scenes, they told us they don’t always agree. So, now, I’m really going to be listening closely as we go through today’s conversation because they both bring some really valuable points of view to the conversation.

Karin Bursa (00:06:17):

So, I don’t know about you, Scott, but I really value that kind of that direct communication. And so, just like the good news, bad news, I’m always going to say give me the bad news promptly, because I’m a little worried about living in a bubble of uncertainty. And if there’s one thing the supply chain struggles with is uncertainty, because we have to plan around it.

Scott Luton (00:06:39):

Right. Well, I would extend that, the global business struggles with uncertainty. But I got to tell you, some days long live the bubble of uncertainty. Just unplug from bad news and focus on the positive. But, hey, all kidding aside, really quick I want to share a couple of special events we’ve got coming up.

Scott Luton (00:06:58):

So, Monica Truelsch is the titan of technology, she’s going to be with us twice in the next couple weeks. Today, you’re going to hear from her and John, as we talked about. And then, February 1st, 12:00 noon, we’re going to talk about how to Harness the Supply Chain Data to Drive Better – and I’ll probably argue faster – First Mile Performance. Karin, it’s going to be a great webinar on February 1st, right?

Karin Bursa (00:07:20):

Absolutely. Yeah. I’m really looking forward to the conversation about that first mile performance. So, we hear a lot about last mile, but there are a lot of things that you said in motion with that first mile. So, looking forward to the conversation there.

Scott Luton (00:07:34):

Agreed. And you can sign up via the easy link in the show notes. You can also go to supplychainnow.com and sign up. And one other note, nominations are officially open, folks. 2022 Supply Chain and Procurement Awards, nominations are open in eight very vast categories through March 1st. It doesn’t matter where your company is, it doesn’t matter where your people are, it doesn’t matter where your products are, the entire globe is eligible to be nominated. And better yet, we are partnering with our friends at Hope For Justice, which is a nonprofit on the move, eradicating modern slavery and human trafficking. And all nomination fees are being donated to our friends at Hope For Justice. Karin, ready to go on this event, right?

Karin Bursa (00:08:18):

Yeah. Absolutely. That’s a win, win, win all the way around. And looking forward to the opportunity to really recognize some of the folks that are impacting the industry of supply chain and procurement. But, also, I really appreciate that Supply Chain Now is sponsoring this initiative for Hope For Justice, because we can change the world.

Scott Luton (00:08:40):

Agreed. Absolutely. And it’s our responsibility to do so. Nicely said, Karin. Folks, learn more at supplychainprocurementawards.com. Okay. Let’s say hello to a few folks really quick. A lot of folks are weighing in on this good news, bad news question. We have opened a can of worms here. I’m going to try to hit these quick so we can get on. Of course, Clay Phillips – ” The Diesel,” is with us here today. Great to see you – “Big show today,” agreed. Joseph joined in from Poland via LinkedIn. Great to see you here today. Michael Avera, “National Hump day.” I can’t see that phrase without that camel commercial from Super Bowl, what marketing genius that was. Let’s see here, scrolling down. Gene Pledger from North Alabama is back with us here today. Ikechekwu – I believe I got that close and I apologize if I didn’t. Let us know how we can make sure we get your names right – tuned in via LinkedIn from Canada here today.

Scott Luton (00:09:34):

Michael says that Blackberry keypad, as we all know, that was game changer. Shakun tuned in via LinkedIn, also from Canada here today. David Glover says, “Morning from Minnesota. Ready for some insight today.” It’s coming. It is coming and we’re on time too. Arnab says bad news first. A lot of folks are wanting that bad news news first. I’m thinking I’m in the minority here. Memory, great to see you back. Memory from South Africa, I believe. “Start with the bad news,” she says. “The good news is just to soften the blow. Rip it off,” is what she says.

Karin Bursa (00:10:08):

You and I are on the same page, Memory. So, thank you for that support.

Scott Luton (00:10:12):

Yes. And one final, Femi says, “Bad news first.” Get this. “The delta in happiness helps deal with the bad news.” Well, well said. Okay. Thanks everybody for tuning in. Hey, keep those conversations going. Keep the comments coming, because we’ve got an outstanding conversation teed up. And, Karin, you’ve got the honor of introducing our guests.

Karin Bursa (00:10:35):

I know. I wish I had a bell or something. But I would like to ask the production team to bring in Monica Truelsch and John Nadvornik with us today.

Scott Luton (00:10:45):

Good afternoon. The swoosh waits for nobody, Karin. We know that. I’ll tell you, it is quite the powerful engine. But, Monica Truelsch – great to see you – and John Nadvornik, both with Infor. Great to see you both here today.

Monica Truelsch (00:11:00):

Hi there. Glad to be here.

Scott Luton (00:11:03):

All right. We’ve had one heck of a time. Karin and I and the whole team having the warmup conversation with y’all in the green room. We talked sports. We talked the upper Northeast. We talked the Cleveland area and a lot more. And, now, it’s time to talk – of all things – Museum Selfie Day. Can you believe it there’s such a thing as Museum Selfie Day? So, before we get into the heavy hitting supply chain expertise that y’all both bring by the truckload, let’s talk about this day that was started by London based blogger, Mar Dixon – that’s a new one for me. And, evidently, on the 19th of January every year, it’s a big thing to take a selfie at your favorite museum.

Scott Luton (00:11:46):

And one more historical note – I didn’t know this – did you know that Robert Cornelius, who happen to be an American pioneer in photography, it’s been said he took the first ever selfie in 1839. How about that? So, all that aside, I tell you, it is technology and history day here at Supply Chain Now via TEKTOK. But I want to focus on the the museums part of this observation. And so, Monica, I think you’ve been anointed our lead off hitter here today. What’s your favorite museum that you’ve ever visited that you can share with us?

Monica Truelsch (00:12:20):

I thought that was a very thought provoking question. I love the Field Museum of Natural History in Chicago. The Met in New York is really exciting. But I got to say in 2020, I added the Samsung Frame TV to my household and it’s designed to be sort of an art installation, and it comes with sort of a partner subscription or art subscription. And I can plug into art museums around the world from the TV that is mounted on my wall. I mean the Berlin Art Museum, the State Museum, Museum of Budapest, the Victoria and Albert in the UK, the Prado in Spain. I had this tour of virtual museums, modern art, old masters, native and indigenous art out of South American museums. And it’s just like a different smorgasbord of art that I can tap into every day. So, I got to say I like them all.

Scott Luton (00:13:21):

You know, Karin, if you heard that – and, John, I’m coming to you next – anytime you hear someone say an art installation, you know they’re a pro, right?

Karin Bursa (00:13:30):

I know. I know. Absolutely. I was thinking the same thing. So, Monica, I guess you have to take your selfie today in front of your art installation with something in the background. But it sounds like you can go around the world here, you know, in a matter of seconds. So, I love that. That’s super cool.

Scott Luton (00:13:47):

I do too. It reminds me of the B-52’s tune Roam. Roam around the world, whatever museum you want to be at.

Monica Truelsch (00:13:54):

If you want to.

Scott Luton (00:13:55):

Yes. If you want to, Monica, right? Oh, cute. I love that. Okay. So, John, that’s a tough one to top. That is a tough one to top. What is your favorite museum you can share with us, John?

John Nadvoknik (00:14:06):

Yeah. I guess good question. I was trying to think about this for a while here. So, I’ll give you more of my interesting trips that had to do with selfies. I’m not a big selfie guy. But I was in Turin, Italy and they have the second largest Egyptian museum in the world there. I don’t know if everyone was aware of that. And we finished our meeting with our customer up and we all kind of busted over to the museum to go see the museum. And I got to be honest, it was one of the first places I ever posted a selfie of myself to a social media account, which I’d also, you know, kind of had to do. So, in reference to that, I will use Turin’s Egyptian Museum as my favorite museum in reference to that. I would say the Lube, but I spent way too much outside on the line once, and that was not a good experience.

Scott Luton (00:14:54):

I love that. All right. John and Monica, thanks for being good players for this fun warmup question. Karin is going to take us into the heavy lifting today. But before you do, Karin, I want to say a quick shoutout – going back to that good news, bad news question – Allison – one of our guest hosts here, a dynamo in her own right – “I’m going to be contrarian and say good news first. It helps me put things in perspective and set the tone.” I love that. Ashish – welcome – tuned in from LinkedIn from India. Great to see you here today. And Dr. Rhonda Bompensa-Zimmerman – one of our favorite folks.

Karin Bursa (00:15:30):

Rhonda, I’m glad you’re here. Good news or bad news?

Scott Luton (00:15:31):

Focuses on wellness in supply chain, and we need plenty of that. So, great to see you, Dr. Rhonda. Okay. Karin, the house is here. Everyone’s here. Everyone’s tuned in to see John and Monica, these titans of technology. Where are we going to kick off?

Karin Bursa (00:15:48):

Yeah. Well, I want to bring us back around to really our core topic today, which is, What’s worse, bad news about your supply chain or uncertainty about your supply chain? You know, right now there seems to be no shortage of bad news, right? The old adage, “If it bleeds, it leads,” that’s what we’re focused on almost every day. And these last two years, it’s been exponentially worse with COVID, with all things COVID impacting all areas of the supply chain from demand through production, through distribution, right through to actual use of goods or consumption of goods.

Karin Bursa (00:16:26):

Monica, you and I had a conversation just a few weeks ago, and we really focused on some of the merits of visibility versus transparency. And I want to encourage our audience to kind of tap into that podcast because you really made me think about transparency a little differently. And it really is different than visibility. That said, I got to tell you that gaining visibility is the number one most often cited goal of any supply chain initiative. And I don’t care what country, what industry, that always comes up from the C-suite. We need visibility, right? So, I’ve got to ask, you have worked with just a multitude of global businesses, Monica, and Infor, certainly, has invested heavily in the area of multi-enterprise supply chain orchestration and supply chain visibility. What does adding real time transportation visibility, how does that help kind of address the complex delays and disruptions and just the pervasive environment that we’re in today?

Monica Truelsch (00:17:41):

Real time visibility, I think, has been a game changer in the world of freight and transportation. For the longest time we were dependent only on milestones. Thinking back to the early days of trucking, when it was the check call and the truck driver would stop at a truck stop, and he’d have a stack of quarters and he’d go to the payphone – remember what those are – to call back into the dispatch office to tell them where he was. You know, “I’m 45 miles outside of Oklahoma City. I’m going to be there in the next hour or so.” And it was these types of events that gave you the milestone progress of a shipment over the road. Go forward a couple of decades, milestones sort of manual inputs of things happening of events are still very much a dominant way of describing ocean and air cargo.

Monica Truelsch (00:18:38):

But on the parallel track, you’ve got the rise of GPS for commercial vehicles and for personal vehicles. And suddenly people are saying, “I can track this truck on a map. I’m going to know within minutes when it’s going to arrive at my warehouse dock door.” And the rise of the aggregators of this kind of GPS-based tracking capability in North America and also in Europe, I think, has just added a whole new richness to shipment tracking capability that we didn’t have before. It’s filling in a lot of the blank spaces in between the events and the milestones that we had before. And it’s really technology enabled. And it took off, especially here in North America, when the government changed the mandates for electronic logging devices just for truck drivers.

Scott Luton (00:19:35):

Right. ELD.

Monica Truelsch (00:19:36):

There you go. And so, suddenly, it becomes commercially viable. And so, there’s been an explosion in real time visibility. And people have glomed onto that. But even our friends at Gartner, the analysts who look at the industry are saying, “Yeah. Everybody’s getting it nowadays, this real time visibility.” But it doesn’t answer that craving for visibility, the knowledge that these chief supply chain officers are really looking for. It is an aspect of visibility. It’s necessary but it’s not enough. It’s not sufficient.

Scott Luton (00:20:10):

As it relates to senior upper rungs of leadership, Karin, I think once they get a little, they want more, they want more. And it’s like the art of the possible is ripped off – talking about ripping off – and it becomes addictive. How much information can we get, that’s kind of the status of global supply chain right now, right?

Karin Bursa (00:20:32):

Absolutely. And I think that, you know, one question that typically I follow up with when a C-suite member is telling me we need visibility, my immediate question is, what are you going to do with that visibility? So, as Monica just said, it’s one thing to know a disruption has occurred. It’s another thing to then put your countermeasures in place in order to do that as proactively as possible. Even if it’s your ability to pick up the phone and tell a customer their order is going to be late versus waiting to report that the order was two days late. So, I mean, there’s a whole different kind of tenor around it in the sense of urgency that I think that we need to, as we talk about visibility in different areas of the supply chain, we consider how we use that visibility to change the game.

Karin Bursa (00:21:24):

So, on that note, I want to hear what John’s got to say on this, because, John, you are helping guide some pretty significant innovations from a product perspective. What’s your point of view on, you know, the topic of visibility and what do I do with it?

John Nadvoknik (00:21:40):

So, I’m going to try to go towards the real time aspect of it. So, I think if we were to go back to how is real time visibility helping someone today, yeah, it reduces the call checks. Yes, I could potentially call my customer and tell them I’m going to be late. But if I have 500 orders running late, am I going to contact 500 customers? Do I have a staff to actually deal with that? So, the question goes back to the fact, how do you make that information actionable? What are you going to do to take that levels of signals that are coming out in the world, which you have increased and have been able to do certain things with? And how do you transform doing something?

John Nadvornik (00:22:14):

So, what we’re trying to do or what I think the market actually is looking for us to do, regardless if we’re moving or the competitors are moving, is the ability to take that real time information and do something with it to make it better. So, can I be more in front of problems? Can I aggregate that data to show you a trend or where things are possibly going wrong? When you go back to your bad news or your good news, sometimes knowing bad news sooner allows me to react faster than knowing it later. Like, you’re almost saying about the customer. So, I think when we look from a technology perspective, we’re looking at how to use that real time data around the other tools that we all like to talk about, which is machine learning and artificial intelligence to try to transform the way people are going to react to certain problems. Can I extend my reach to visibility? Is it just around the transport component of it? Or do I extend it around the inventory component of it? So, do I have other areas or even the supply side of that? So, how much is that late shipment going to make me impactful? Yes. That might be a problem for the shipment. My inventory’s good. Maybe I need more information.

John Nadvoknik (00:23:20):

So, when you think about visibilities, how do you put some context around those problems? Tell people make better decisions. Should I call the customer? Should I not call them? I mean, generally, most people think you should call them if you’re going to be late. There might be reasons why you wouldn’t. But maybe it’s going to be really late and I get them another supply and say, “Hey, not only is it going to be late, I’m not going to get that to you on time, but I have other supply from this other place where I can get it to you on time.” How can we get that information into the people’s hands that need it to make those decisions and make those actions?

John Nadvoknik (00:23:49):

And I think a lot of that has to do around understanding the trends that’s kind of around your machine learning. And how do you automate some of that process, more around the AI to make it a little bit better. But it is capturing all that data, rationalizing it down, and being able to make it actionable. And I still think on the real time side, we’re still far away from that. I mean, when I say far away, we’re probably years, like a year. But we’re not, like, decades from where we at. But, now, we have the data and people are trying to figure out how to get better use of that.

Scott Luton (00:24:20):

Agreed. If we could just get to the point where you’re predicting what my kids are going to want to wear to school, say, next week, just give me seven days lead time. That’d be great if we can get our technology there.

Scott Luton (00:24:30):

Hey, really quick, Karin, before we move forward, I want to recognize a couple of comments here. Joseph says, “When you have a big complex global supply chain, it can be really difficult to have full visibility of the chain.” As part of what John was saying there, we’re ways away from really having that or as much as everyone wants, maybe. Silvia talks about boots on the ground, the ELD has been really challenging for folks there. Memory talks about visibility is about the security of supplying and being responsive to customers. I love that. Also, Silvia, says “Learning to discern between a real need and arm chair logisticians.” That is a great point. Kind of what all of y’all kind of touched on, what are you going to do with it? Yeah, we can work to get it to you, but what are you going to do with it? So, I love that.

Scott Luton (00:25:16):

All right. So, Karin, very popular conversation playing out in the skyboxes here. Where are we going next with John and Monica?

Karin Bursa (00:25:24):

Yeah. So, I think one thing that’s important for us to all realize is that the reason there is a digital supply chain industry, that there is technology that has evolved over decades now is because we’re dealing with a couple of major themes, but just tons and tons of variables to be considered in those calculations. So, uncertainty is a big part. The supply chain hates uncertainty. It’s hard to calculate uncertainty as a part of the measure. But it’s also getting out in front of what John mentioned and what Scott mentioned which is lead time and what do I do with the lead time I have. And that lead time is different, depending upon where you are in the supply chain. If you’re doing planning and forecasting versus the expectation of inbound goods or a shipment to a customer.

Karin Bursa (00:26:20):

So, Monica, as you think about this and you think about some of the key trends, in your work around strategy for supply chain performance, what are the themes that are coming out regarding uncertainty? Because we’ve talked about collecting this data. I like how John said, you know, there’s just this multitude of data. We can literally be drowning in data, but starving for information. How do we kind of close that gap?

Monica Truelsch (00:26:52):

Uncertainty, I think, is the overriding characteristic of the supply chain chaos that we’re operating in today. And it’s, frankly, at a scale that the industry I don’t think has had to deal with for a long, long time. Logisticians, supply chain folks, they’re in the business of working through problems. They have exceptions all the time. The truck is late. There’s a fire on board the ocean vessel. The dray carrier broke down, it can’t make the appointment at the port. My parcel carrier has just limited the volumes of shipments that they’re going to pick up for me because they’ve got too many other competing contracts for it.

Monica Truelsch (00:27:37):

So, getting through bad news, getting through problems is what supply chain people do. I mean, that’s the focus. The uncertainty that we have in global supply chains, especially right now, is, I think, the whole new wrinkle in the game. It’s not just how long is it going to take that ship to cross the ocean. How long is it going to wait at anchor before the port is going to be uncongested enough for it to actually birth and have my goods unloaded? How long do we have to wait to get empty containers to export our goods? Because there’s a huge container and chassis imbalance across [inaudible].

Scott Luton (00:28:23):

Containergeddon, Monica. Containergeddon, I believe, right?

Monica Truelsch (00:28:26):

There you go. There you go. And the chassis, you don’t move containers without chassis as well. So, that’s the other component. The more parties you have to a movement of goods, the more components, the more legs in that move, the more uncertainty can creep into the situation. And I think you can track the progress of that truck in your little map. You can track the dots for the ocean vessels moving on that little map. But there’s so much uncertainty about the start and the stop of each leg in these multi-leg global moves that has never been there before. The just in time supply chain design is predicated on being able to have repeatable movements and legs in between each of these things.

Monica Truelsch (00:29:12):

And we don’t know. Things are taking longer, but we don’t know how much longer. And it is this uncertainty. Like the financial markets, they can price in risk for certain investments, but they can’t really price in uncertainty and what that means for a given business investment. And I think that’s the big challenge for us, is that, there’s so much that we don’t know at the start and the stop, all of these handoffs in our supply chains right now and it’s making people crazy.

Karin Bursa (00:29:41):

Yeah. Yeah. Absolutely. But I love how you started that with, you know, supply chain roles and supply chain people are problem solvers by nature. So, we are used to solving very complex problems and being focused on service and quality in that mix. John, you mentioned something in your remarks just a moment ago about how do we translate that visibility into action. Can you give us a couple of examples of what you’re doing, what you’re working on at Infor that’s helping practitioners translate visibility into action?

John Nadvoknik (00:30:21):

So, just playing off with some of Monica’s comments and even maybe rooting this back to your first statement around the real time visibility, so when you think about the data you’re collecting today versus what you might have collected in the past, you can have a higher reliability because of that real time data and not the dependency on events.

John Nadvornik (00:30:43):

So, for example, I need to know I got picked up. Does the carrier send that to me on time? Maybe, maybe not. But if I geofence a location, I can know it actually left the location when it went on there, assuming it got loaded, which is still a problem you have. But let’s move past that problem assuming it gets on the truck. So, I can tell. So, I have that information sooner in my entire supply chain.

John Nadvoknik (00:31:06):

So, having and being able to fuse that real time data with event style data allows me to kind of blend a better picture of what’s actually happening all the time. So, now, the question is, how do I use that data to answer your question that started this point off, which is, let’s say for example, a blank sailing occurred. I expected it to be on a vessel. It didn’t occur. Do I automatically rebook the next structure? Can I make that a little faster for them? If I’m running late to a port, can I let them know it’s running late? Maybe make a recommendation on you had a rail move, maybe a team drive move will allow you to save money. How can we help customers at least give them the options that are available, not automate that all the way today, because I think no, one’s really ready for that total automation.

John Nadvoknik (00:31:53):

But be able to, in the context of that exception or the context of that problem, give them options that are available for them to address the problem, give them the times and the cost, and that’s really what we’re working at right now is how do we make them make better decisions or resonate that information as opposed to having to make a whole bunch of phone calls. Give them the context of the problem that’s having in there and give them some options for resolutions that they can execute right away. But, obviously, we’re not going to automate that execution. Not at the moment. I don’t think anyone is ready for that. It’s like are you ready for your car to drive you yet? I’m not sure. But I’m not, I can tell you that. So, I think most customers are not ready for someone to basically just the systems to make all those decisions for them. We’re not SkyNet yet.

Scott Luton (00:32:39):

Isn’t it funny? We’re all pining away for the old challenges and the old uncertainties. The good old days when you didn’t have to get creative seemingly every hour of the day. I’m going to share a couple quick comments from folks here. Memory talks about forecasts are improved by visibility too. Great point there. She continues to say, “The complexity that is now ingrained in supply chain networks requires visibility, which will help simplify a lot of these challenges.” Excellent point. Memory, you’re on fire today. Seema says, “Key strategies for supply chain in the uncertain business world in global supply chain. Monica, it’s very true.” I think I might have butchered that just a bit. Well, I think the main point she’s making is there are some key strategies that Monica and John both are mentioning to help root out a little bit of uncertainty in global supply chain. And that those real time scenarios, which are so critical that we’re after. Excellent point there, Seema. Monica, do you want to respond really quick to Seema? She’s pointing out some good news you’re bringing us here today.

Monica Truelsch (00:33:40):

Yeah. So, the real time scenarios and the uncertainty, and I think Seema may be alluding to the complexity of all the participants in the supply chain. So, again, in a global supply chain, an inbound move from another country, for instance, there are so many handoffs of the goods and modal changes across border shifts and so forth. To get visibility to all of that, it’s not just a transportation challenge. It’s really an integration with your suppliers. It’s integration with your freight forwarders, with your 3PLs, perhaps with your customs broker is involved as well too. And it’s this holistic approach to visibility. Something that we can talk more about the transparency of the global supply chain that really brings power to the investment in this type of technology, connectivity, and into the tools that can make sense of all the data that you’re bringing in from these connected parties.

Scott Luton (00:34:38):

Agreed. John, please.

John Nadvoknik (00:34:41):

One thing I was just thinking in that whole concept that Monica brought up, we talk about real time visibility capturing those sensors or whatever that might be. Theoretically, I plug a big old sensor on the back and I can track my package with this whole supply chain. As Monica noted, there are those handoffs and those handoff points that you have in your supply chain, you’re still required to have some aspect of people involved. And so, you’ll always have that problem on integration, let it be a customs broker point, let it be transloader, let it go through a terminal on the other side. So, as good as you can get the real time movement aspect of it, you still have to focus on the points of handoff, which I still think is a key area in which getting visibility and even some aspect transparency as far as labor and things like that that would be also very beneficial for folks. I think we focus a lot on the movement, but I think Monica brings up all those good points there.

Scott Luton (00:35:31):

Agreed. The handoffs is where you can really get in trouble if we don’t get these right. I want to share this. Racquelle says, “Monica, supply chain people are the problem solvers. Yes.” And the overarching theme there that we’re all speaking to is how we leverage technology to allow our people to bring more value to the table and solve more problems and bigger problems and find new value. So, I love that. Let’s see here, folks, if you show up as LinkedIn User, it just means you’ve got a privacy setting on your LinkedIn profile that doesn’t allow us to see. This is Lenore that says, “Lead time depends a lot on where you’re located. So, you need to understand, not only your business, but also your location. It’s difficulties to ship in and out. You’ll need to forecast accordingly.”

Scott Luton (00:36:15):

And, of course, warehousing networks and all the planning that goes into where to locate different things, it’s a fascinating time to be in supply chain, for sure. And, finally, everyone’s talking about reality. I love Silvia’s point here. Silvia, we’re going to have to have you back on because as she points out there, she’s in the port every day checking on exams, chassis, truck power. “I love to share how it works in the real world,” supported, of course, by technology. Silvia, we’ll have you back on. And by the way, folks, Silvia makes some of the best jams and jellies in the Southeast. So, we’ll have to have Silvia back on.

Scott Luton (00:36:50):

Okay. So, speaking of ports, that is a great segue to the next question I want to pose starting with you, Monica. So, this is good news. I promise you you’re going to find some good news. We have had some relief in the ports. Yes, Port of Long Beach and the Port of Los Angeles both have Twitter accounts. Who else loves that besides me? I love you can just peek in there. Now, you might get a little extra good news rather than some of the reality, maybe on social. But, hey, I still love the fact that you can check and see what’s going on in our ports. So, still, the reality is west coast and other port congestion continues. Monica, I love to get your thoughts on import shipments. There’s inbound goods coming in from overseas and how this visibility and how this technology we’re talking about can drive real, tangible benefits.

Monica Truelsch (00:37:43):

Absolutely. And I’m going to give a bit of a shoutout to the webinar that we have coming up occurring on the 1st of February, we talk about first mile. The first mile of the supply chain, these complex, generally, global international moves, they’re multimodal. There are many parties involved in these. It’s a far more difficult visibility challenge than an outbound truckload shipment tracking, for instance. And it’s where the choice of your technology partners and their ability to connect and onboard and, really, to mesh together the many diverse sources of information and data that you’re collecting on these inbound supply chains. But then, to make sense of it on a common data model so that you know what the impact of an exception upstream means for all of the downstream components in that process as well too.

Monica Truelsch (00:38:44):

So, John alluded to the handoffs and the issues there as well. The earlier in the supply chain that you can spot a problem that is developing, the more cost effective options, the broader the range of options you have to actually mitigate disruption and problems downstream. So, I think for companies to invest in their first mile visibility, and, again, it’s not strictly a transportation solution at that point, it’s very much a trading partner, logistic service provider, network connectivity challenge for you on the first mile. The more that you can do and invest to identify those problems upstream, the more you can avoid disruption, that cascading flow of problems that ends in disaster, because your production line stopped, the parts didn’t show up when you needed them to assemble your Ford trucks, the materials didn’t show up for your production line, your entire Christmas holiday shopping for the market in Brazil went up in flames at a vessel at sea. These things are, I think, top of mind for companies to deal with right now. The focus on last mile has been very important because of the Amazon effect. But you’re not going to be able to ship those goods via UPS, via FedEx, via Amazon’s logistic service if they’re not in your warehouses, if your production lines are down because they haven’t come in for that first mile yet.

Scott Luton (00:40:25):

So, two quick points, and then, John, I’ll pose a question to you here. First off, since we’re picking on Ford trucks, did anyone see the commercials if your power goes out, you can use your Ford trucks to keep that football game on? So, y’all check that out. But, secondly, final mile or first mile, you heard Monica and, of course, John talk about that throughout. I saw a stat the other day, the final mile autonomous market for 2021, it was about $900 million in terms of the market cap. By 2030, a $5 billion market. Holy cow. So, if final mile is new to a handful of y’all, get ready, you’re going to hear that a lot the next eight years. Okay.

Scott Luton (00:41:08):

So, John, let’s talk about a little twist on the question here. So, in your role, vice-president of product management at Infor, how are you able to take what’s happening? You know, we’ve talked about all these different scenarios, these challenges, this uncertainty, all these different layers, and roll all that into solutions that, again, are about driving visibility, transparency, or – heck – just managing, simply managing uncertainty. There’s big value there, John.

John Nadvoknik (00:41:35):

Yeah, there is. And I think what we’re trying to do is really look at, as we talked about earlier, where can we affect change. I mean like most providers out there, we’ve done a pretty good job on the milestones and even cap some of the real time data, where we’re really trying to focus is around those handoff component. Can we give you better visibility into the areas that you are handing product off? That is not just giving you the visibility, but giving the analytics, trying to understand that we talk about it being a problem.

John Nadvornik (00:42:06):

I think you mentioned, you know, that supplier trading partner could be the terms in which you purchase goods. Maybe there’s a shift you want to do there because you can speed it up. Maybe the way that you transfer those types of things, trying to help folks show them where problems are occurring, and give them action to understand the data underneath it to what’s causing the problems. It could be lots of different things. It could be sailings. Maybe I’m in the wrong port. Maybe I need to look at something different. I think it’s being able to give them that data and then help them guide them through some problems and solutions they’re trying to get through.

John Nadvornik (00:42:41):

So, tech-wise, we talked about the real time capturing some different types of data. There’s also, you know, set of APIs. There’s better connectivity to a lot of the forwarders and carriers that existed than what existed a few years ago. When I say a few years ago, I’m talking five, not even ten. Everybody’s elevated their games in those areas in a much faster pace. And I know we blame a lot of it on COVID in a way, but a lot of that trend started back when the tariff started to shift. All the things started moving out of China. That required people to start thinking about their supply chain problems differently. You know, what can I do around that type of movement that made it a little more nimble? I think it would’ve worked out a lot great if COVID never happened. I think we would’ve flushed that out in a much smoother timeline.

Scott Luton (00:43:26):

That would have my vote, John, just saying.

John Nadvoknik (00:43:28):

Well, I mean, where would the excitement be then, Scott? [Inaudible]. But the point there, I think, is all that just kind of allowed us to move maybe a little quicker. A lot of people were still caught off guard. But there were some good things that were done prior to that to make it a little bit better. So, again, to just kind of answer that real quickly, it’s we are working harder to find the areas where we can’t get real time visibility because it’s handoffs. How do we get better data, better integration? Integrate that up and give that to the users. And, again, like Monica said, lot on last mile because of the Amazon effect, not much in that area, that’s actually causing people problem having your shelves empty. I can’t get any Arizona iced tea right now. I mean, that’s kind of [inaudible].

Scott Luton (00:44:12):

I love that. And don’t interrupt the Arizona iced tea supply chain, folks. The White House will be calling you. Really quick, John, as an aside because we’re not making light of COVID at all. One of the thoughts that came to my mind as you were describing that, everyone blames on COVID. Of course, COVID changed everything. However, as probably we can all agree, there were lots of shaky, ill performing businesses. I can remember one that I was a member of, like a club, that had horrible service, horrible food, bad event management. And, of course, they went out of business during COVID. But they were all not a strongly performing organization for a long time. But everyone blames COVID. In many cases, the innovation that COVID is going to drive is going to allow us to do more as an industry. And it’s a big dark cloud and a lot of challenge and pain and suffering, but, man, it’s going to get better and allow us to do more as an industry. Karin, your thoughts?

Karin Bursa (00:45:20):

Yeah. I totally agree with the last part of that comment, is, COVID is an unfortunate thing that’s impacted the world and impacted many of us, personally as well. But it has accelerated the adoption of digital supply chain strategies and the need to evaluate multiple scenarios more rapidly. So, I think many companies have leapfrogged their personal or their corporate transformations. I think there’s still, as John said, decades of opportunity ahead of us. But I think that most companies on a global basis have made significant strides forward over these last two years because supply chain has become such a priority and top of mind, and is what’s discussed in those C-suite meetings because of the challenges and disruptions and the questions about what do we do about it.

John Nadvoknik (00:46:21):

May I add one point to that, Scott? I think the interesting aspect of that is, yeah, there’s a lot of technology shift, but I think companies are looking at their business, and how they work with their partners, and the quality of the information, and where they hold them as far as that standard is. I think that’s all moving forward. They look at their business, as you noted, looking at their business differently to hold other partners that are critical in their supply chain that they might not have thought about as being important to a different level of standard in the companies that are pushing ahead or doing a really quick job into that area as well as adopting technology.

Scott Luton (00:46:54):

Agreed. Agreed. And it’s a fascinating time these last few years, whether you’re looking at technology, you’re looking at the employee experience, you’re looking at consumer experience. It really is mindboggling. Just all the gains that we’ve made in light of these deafening challenges and uncertainties. So, that’s a good story here.

Scott Luton (00:47:14):

Karin, I know we’re running short on time with, I think, this intriguing conversation with Monica and John. I can’t get to all the comments in the skyboxes. As we start to kind of wind down, what’s next with Monica and John here?

Karin Bursa (00:47:27):

Well, Monica, I do want to ask you just really quickly to express your point of view on the difference in visibility and transparency, because we’ve talked about it a couple of times or alluded to it here. We’ll ask our audience to go and listen to the full podcast to really get a more comprehensive view of it. But give us kind of the quick and dirty on how you see visibility as different from transparency in the supply chain.

Monica Truelsch (00:47:55):

Yeah. Great question. Visibility, to me, is drilling a hole in the wall, the barrier, between you and what you want to see, and putting your eye to it so you see something that you could not see before. Transparency is replacing that wall with a pane of glass. And when we talk about supply chains and the many participants that make it work nowadays, global supply chains in particular, gaining visibility to one aspect, I think, Scott, as you mentioned before, too, it wets the appetite for all of the things that you can’t see. And so, if you focus your technology investments just on visibility of one aspect or one process, I think you are missing the business value of investing in broader connectivity with those trading partners, with your carriers, with your 3PLs, your logistic service providers that allow you to explore the bigger picture.

Monica Truelsch (00:49:03):

It’s not just if this is moving, but has it departed? Is it ready to go from the supplier side of things? Has my supplier completed the packaging and shipping and labeling what’s ready to actually stuff in the container? It is the thinking about making your supply chain more connected overall to remove all of the blind spots rather than just focusing on tracking one particular aspect of it, the product in motion and maybe the transportation part of things. Because when you talk about the inbound supply chain and global supply chains across border, across ocean, tracking a single mode, or a single carrier, a single truck, or a single ocean vessel is no longer sufficient to dispel the complete uncertainty about when your stuff is going to get where you need it to be. And that’s the essential question, it’s not where is my stuff? It’s, is my stuff going to be here when I need it?

Scott Luton (00:50:13):

I’m glad you shared that because I was just about to say, “Where is my stuff, Monica?” But that’s not the question.

Monica Truelsch (00:50:17):

That’s not the question. Yeah.

Scott Luton (00:50:19):

Okay. I’ll share a couple quick comments and then, John, I’ve got a question for you as we start to wrap here. Let’s see here. Silvia says, “Excellent, Monica. We need more transparency in global supply chain.” Yes. And I can’t find her comment, but Silvia was touting the virtues of the Port of Charleston. So, she’s a big advocate of the Port of Charleston, which they’re on the move, for sure. Ikechukwu says, “Thank you, Monica, for the lay down emphasis on visibility and transparency and supply chain.” See, John and Monica both get new members of your fan club. Memory makes a good comment here, this goes back to, I think, we’re all trying to speak to a moment ago. Memory says, “COVID flushed out a lot of issues that were already -” they were already “- buried within our systems. It’s brought some solutions to forefronts and more solutions.” Memory, that’s what I was trying to say. Thank you very much for eloquently putting it better than I could. So, great point there.

Scott Luton (00:51:15):

Okay. So, what I want to do as we start to wrap – and we’re going to circle back on the good news, bad news question in a second, and then we’re also going to make sure folks know how to connect with our two titans of technology here – John and then Monica, John, where do folks get started in all of this? When it comes to, especially, inbound shipments or in general, where can folks get started?

John Nadvoknik (00:51:38):

Well, I think, obviously, you’re going to need that homegrown or buy some software is going to actually be kind of one thing. But where a lot of customers should really think about starting is how do I get better visibility to – again, I’m going to use this term – supplier handoff, to forwarder/forwarder, to on vessel or on plane, if you’re thinking about a pure inbound. So, that means – going to Monica’s transparency – how do I share with my parties involved what’s actually needing to happen at those areas? So, if we look at where a lot of people excel or get at that level of visibility, it’s their ability to share their order, what’s going on, when they need it. Maybe not all the content, but being able to share that data with the participants that need to get that order from the origin to wherever they’re trying to get it to, their destination, maybe if it’s a drop ship to a customer, but being able to share that. So, you have to be able to open up a little bit.

John Nadvornik (00:52:32):

It’s kind of like, you know, relationship, you got to open up a little bit in the area of being a little bit vulnerable in these areas to your partners so that they can actually help you kind of move along the supply chain. Because if you’re going to try to go it alone, you’re going to have the blind spots that people are looking for. And, again, if you get into that, you can get a little bit of visibility and you get a little bit of value. You can give a lot of visibility and get a lot of value. So, use the relationship, you can go with that a little bit if you want there, Scott. So, that concept is really what I think people need to do is how do I share the information that allow my business partners to perform better on their behalf. And I need to understand what they need so that I can get that information to them. A collaborative platform that allows people to work on that is a great way to start. It might not be attainable for everybody, but it is a great way to start.

Monica Truelsch (00:53:21):

Amen. Amen.

Scott Luton (00:53:21):

I love that. I love that. Really quick, Jeremy Bodenhamer on a webinar we did yesterday was talking about authenticity in supply chain. And we hear authenticity mentioned in a lot of different ways, but he really hammered supply chain. But, John, you mentioned vulnerability, but those true real relationships with your suppliers and with your supply chain, that’s when – man – trust, you can move mountains. So, I love that comment. I love how you baked it in the relationship point there, John. All right. And Amanda, as I’m hearing in my ear, love that too, John. So, Amanda is going to get some good traction out there. Monica, what would you add to that question of how do you get started? Where do you start? What would you add?

Monica Truelsch (00:54:05):

Wow. It depends a lot on the immediate pain points that a company is dealing with, of course. You might have a really, really great supplier management situation, your direct procurement team, they’re all plugged into your suppliers, you kind of know what’s going on there. But maybe your forwarder solutions, if you’re dealing with global input, you’re having to navigate between the unique technology portals that each of your forwarders are working with and the different geographies that they handle. Maybe it’s time to think about having a visibility or an orchestration platform for your global supply chain that lets you feed all of those forwarder information streams into, but that gives you that single pane of glass, that consistent view across all of your channels.

Monica Truelsch (00:54:57):

I would emphasize definitely looking at the first mile of your supply chain. Karin, I think you and I talked in the podcast last of about how much technology investment has been going into the last mile in the last several years. And what we’ve certainly seen from Infor in the recent years is that companies have been under investing in that first mile. Companies that had even purchased our nexus solutions, but were in various phases of implementation in 2020 when things just kind of froze up around the world, they decided to accelerate the aspects of their technology implementations that focused on visibility to their supply chain partners, to their logistics service partners, to the ocean and air cargo aspects as well because that’s where they felt the pain.

Monica Truelsch (00:55:51):

And to say that it’s not important where you start, it’s important that you start today, and that you begin to move towards that transparency. Because as John very rightly pointed out, there is mutual benefit from visibility and transparency in helping to eliminate waste, in freeing up capacity in transportation, in attaining financial goals for both buyers and sellers on the transportation side and on the good side for international transport. So, there’s upside all along the value chain and supply chain if you look to invest in transparency, not just invisibility, and you bring your partners, your trading partners, into that story as well.

Karin Bursa (00:56:44):

Scott, I know we’re up against time, but before we let John and Monica go, I got to ask, what’s worse? Monica, what’s worse, bad news about your supply chain or uncertainty about your supply chain?

Monica Truelsch (00:56:58):

Bad news is something we deal with every day. Just get rid of that uncertainty so we know how to deal with it.

Karin Bursa (00:57:05):

All right. John?

John Nadvoknik (00:57:05):

I’m going to wait the bad news, because we’re always planning for the uncertainty. It’s the bad stuff that hurts us a little bit on these structures. So, I think we’re all adjusting to uncertainty fairly well in the supply chain. I think when we get hit with a port strike all of a sudden, to me, that’s bad news and it’s a little bit of uncertainty, but that really hurts us for [inaudible].

Scott Luton (00:57:26):

Well said. You know, that good news, bad news conversation – holy cow – we could dedicate it. It feels like a couple of days of content and conversations around that. Folks in supply chain really digging what y’all were sharing about that, John and Monica. And, of course, your technology and supply chain observations and discussion here today.

Scott Luton (00:57:45):

Folks, make sure if you enjoyed today’s conversation, check us out on February 1st, where we’re welcoming Monica to another conversation via webinar. You got to sign up for that one. The link to sign up is free, it’s in the comments. And you can also learn more at supplychainnow.com.

Scott Luton (00:58:03):

So, as we thank Monica and John for their time, big thanks to Monica Truelsch, Senior Director Supply Chain Management Strategy with Infor, and the world’s biggest Cleveland Browns and Cleveland Guardians fan. I think I got that right. Monica, thank you so much.

Monica Truelsch (00:58:19):

My pleasure. Thank you very much for having me, Scott. Thank you, Karin.

Scott Luton (00:58:22):

You bet. We’ll see you in just a couple of weeks. And, John Nadvornik, we really appreciate your time here today – Vice-President Product Management with Infor. Perhaps the largest New York Giants fan. They’ll be back. They’ll be back on the face of the earth. Is that right, John?

John Nadvoknik (00:58:38):

I’m not sure. I’m not sure. Thank you for that wish.

Scott Luton (00:58:41):

Well, we really enjoyed y’all’s take. I love the analogies. Karin, we’ve got a ton of t-shirt-isms. Thank you so much to John and Monica. We’ll see you again very soon.

Monica Truelsch (00:58:51):

Thank you.

John Nadvoknik (00:58:51):

Thank you. Have a great day.

Scott Luton (00:58:53):

That was chuck full, Karin. That was one heck of a discussion. And, you know, with John and Monica, there’s so much there but we’re still just scraping the tip of the iceberg.

Karin Bursa (00:59:06):

Absolutely. And I liked John’s perspective on that, where he talked about from a technology perspective, it sounds like they’ve got a good decade of innovations already planned or targeted out on those longer lead time items. But I also like the sense of urgency around just simply getting started. Getting started today and think about both visibility and transparency, not just from your role in the supply chain or your business’ role in the supply chain, but think about it with your customers and think about it with your suppliers, your carriers, your partners as well, because there’s benefit to be derived across the board. And I think that that’s one thing for us to all keep in mind, is, we can be a great supplier and a terrible customer, or we can be a great customer and a terrible supplier, depending upon on what relationships we’re looking at. So, I agree, lots of opportunity.

Scott Luton (01:00:06):

Agreed. And, hey, your visibility and transparency strategy cannot start and stop with it at your four walls. These handoffs and exceptions that came up in today’s conversation, that’s some of the secret sauce. You got to get it right. You got to get that right with your partner. So, I really enjoyed Monica and John’s conversation. I’m tickled to have Monica back. We had to go through her agent, I think, to get her back on February 1st. John’s agent was playing hardball, evidently. But I’m looking forward to having Monica back with us on February 1st.

Scott Luton (01:00:38):

Lots of comments here. Let’s wrap on this. I really appreciate this comment here. Alina, “Thank you so much for the interesting conversation, especially about investment in the first mile suppliers, 3PL providers, et cetera.” Excellent point. Seema wants to know about that museum in Italy that John was mentioning on the very frontend. So, we’ll see, maybe they can get connected on LinkedIn. And by the way, folks, make sure you do follow and connect with Monica and John on LinkedIn. And you can learn more about Infor, of course, at infor.com.

Scott Luton (01:01:08):

Let’s see here. Seema also says, “Supplier management solutions and navigation with different geography explained by Monica is recommendable. Explanation is very real and true.” I tell you, Monica is getting all kinds of fan support here. Racquelle says, “Thank you for all the amazing information.” Tom says, “Great SCN segment.” I appreciate that. Clay has dropped in the link. Again, that should be in the show notes, but this is the webinar on February 1st. And, finally, Silvia, defender of the Port of Charleston, which I love. We got to have Silvia back. She says she’d rather be the bearer of bad news so that you can collectively find a solution.

Karin Bursa (01:01:45):

I agree with you, Silvia. And I think that Silvia has quickly become the ambassador of the port. So, not to the defend her, but the ambassador. She’s always had a great point of view.

Scott Luton (01:01:57):

Sorry. When I said defender, I meant it like a defender of planet earth, like a cartoon or something. I might be getting damages.

Karin Bursa (01:02:04):

I sure it is. I ‘m sure it is.

Scott Luton (01:02:06):

Ambassador Karin is a better way of putting it. I love that. And Michael, yes, this whole conversation is going to be available on demand via social and via podcast here really, really soon. And, Kim, hey, have a great time in Dubai. You missed a great conversation. You’re going to have to tee it back up and we got to get your thoughts on it. Okay.

Scott Luton (01:02:24):

Karin, we’ve kind of talked about some of our favorite moments. This was a rock and roll conversation with Monica and John with Infor. One quick, where can folks find TEKTOK, Karin?

Karin Bursa (01:02:34):

Yeah. TEKTOK, anywhere you get your podcast, please follow us, join, get notifications. And I’d love to hear your thoughts on topics to cover in some upcoming sessions. So, don’t be shy.

Scott Luton (01:02:45):

Don’t be shy. Folks, hey, we’ll keep talking about good news versus bad news. But if you’re in supply chain and global supply chain, you’re certainly part of the good news. And we appreciate all those efforts, all the hard work, the innovation that keeps global business moving forward.

Scott Luton (01:03:00):

On that note, on behalf of Karin Bursa and the whole team – big thanks to Shantel, Katherine, Amanda, Clay, the whole gang. Big thanks to our guests, Monica and John with Infor – Scott Luton, challenging you, do good, give forward, be the change that’s needed. And on that note, we’ll see you next time right back here at Supply Chain Now. Thanks everybody.

Intro/Outro (01:03:20):

Thanks for being a part of our Supply Chain Now community. Check out all of our programming at supplychainnow.com, and make sure you subscribe to Supply Chain Now anywhere you listen to podcasts. And follow us on Facebook, LinkedIn, Twitter, and Instagram. See you next time on Supply Chain Now.