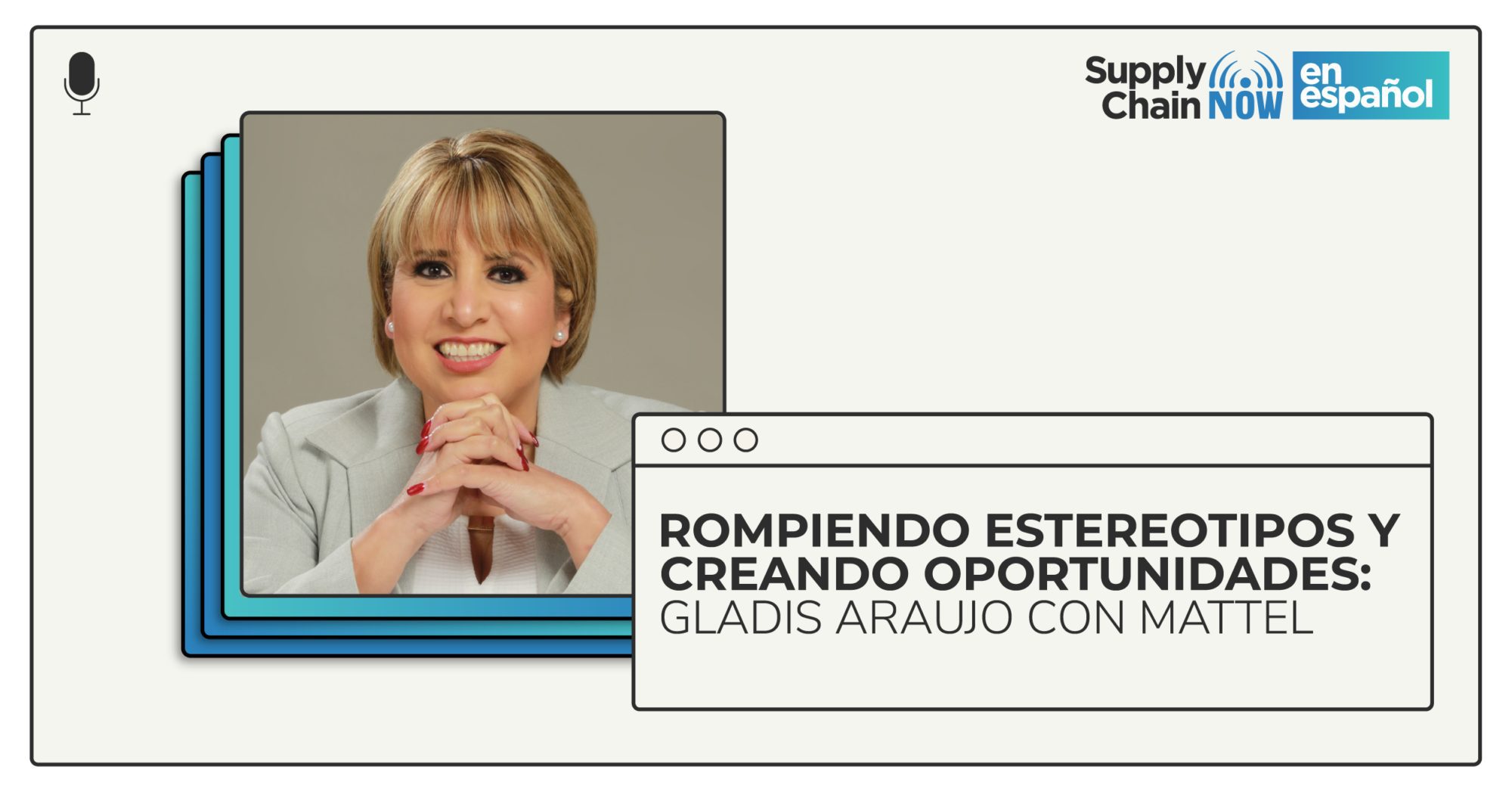

Resumen del Episodio

En este episodio de Supply Chain Now en español, el presentador Enrique Alvarez le da la bienvenida al programa a Gladis Araujo, VP de Calidad Global de Mattel. Escuche a esta dinamo de liderazgo, mientras habla sobre su amor de toda la vida por el aprendizaje, su experiencia en ingeniería y calidad, y su extraordinaria carrera. Aprenda de Gladis mientras comparte su mensaje de ser valiente, romper los estereotipos de género y la importancia de la alianza y la tutoría. ¡Escuchen!

Transcripción en Español

[00:00:37] Muy buenos días y bienvenidos a otro nuevo episodio de Supply Chain Now en español. Mi nombre es Enrique Álvarez y tengo el gusto y el placer de entrevistar a una mujer que ha hecho muy buena carrera, no solo en Mattel, sino con muchas otras organizaciones y tengo el placer de platicar con ella. Vicepresidenta de Calidad Global de Mattel, Gladys Araujo. Cómo estas? Muy buenos días.

[00:01:01] Pues muy contenta de estar aquí con ustedes en su Play Change Now en español. Muchísimas gracias por la invitación, Enrique, un placer.

[00:01:10] El placer es todo nuestro y bueno, en base a lo que platicábamos antes de empezar a grabar este show, creo que tenemos mucho, muchos temas de que de que comentar y es un placer tenerte aquí con nosotros para todas las personas que nos están escuchando en Latinoamérica o en todas partes del mundo. Si les gustan este tipo de entrevistas y les gustan y les motivan este tipo de pláticas, no dejen de suscribirse. Y bueno Gladys, empecemos un poco con contigo. Tú cuéntanos un poco de tu vida. Dónde naciste? De dónde eres?

[00:01:40] Claro que sí. Mira, pues yo soy regia, como nos dicen aquí en Monterrey. Nací en Monterrey, México, nací, crecí aquí, soy la mayor de cuatro hermanos, tengo un hermano y tres y dos y dos hermanas. Tradición una familia tradicional mexicana es mi papá, pues trabajo de tiempo completo, mi mamá dedicada al hogar. Mi papá es ingeniero civil y trabajó por más de 30 años en una de las industrias de aquí de vitro, pero siempre tuvo miles de trabajos e incansable para poder sacar a la familia adelante. El como su carrera es ingeniero civil y apasionado de la construcción, pues siempre tuvo trabajos, este por fuera de construir escuelas, plazas, puentes, edificios, casas de todo un poco como él dice y pues él lo que su sueño de toda la vida y su propósito porque así no lo manifestaba a nosotros, era asegurar que sus cuatro hijos, pues tuvieran una carrera profesional y él buscaba y anhelaba que fuera en una buena institución. Entonces todo su trabajo, todos sus ahorros, todos sus enfoques iban a eso. Y algo que él mencionaba mucho, es decir, la mejor herencia que nosotros les podemos dejar es la educación. Y de ahí, pues ustedes se abren paso también. Otra de las cosas que yo aprendí, que es el sello que llevo hasta el día de hoy de mis padres, en especial de mi papá, es el el aprender continuamente en aquellas épocas. Pues la verdad no es como hoy de que había internet, había una librería en cada esquina, es difícilmente conseguir libros en inglés, etcétera, y la forma en que se hacía en aquellas épocas era no sé si te acuerdas Enrique, o te tocó que te vendían así casa por casa y unas enciclopedias.

[00:03:35] Consulté la Enciclopedia Salvat y la Británica

[00:03:39] Y de todo quiero en colecciones bien grandes, de más de cien, doscientos libros y no sé, de todo

[00:03:47] Un patrimonio. No era si era realmente una compra fuerte, porque no estaban baratas, porque

[00:03:53] Esta era una inversión muy, muy fuerte. Pero ellos este como creían muy firmemente en la educación, que el típico de que pagos semanales o pagos mensuales y ya no sé, pero era una inversión bastante grande y pues fue Navidad para mí el día que llegué a la sala de mi casa y vi todo el monstruo de cajas llenas de libros y pues te puedo decir que prácticamente los leí todos, este mi niñez hasta la adolescencia y pues lo que aprendí es amar a los libros. Aprendí a que a través de los libros vives muchas vidas y ganas muchas experiencias y a partir de ahí pues me considero como dicen en inglés On life long learning de continuo aprendizaje y pues hasta el día de hoy

[00:04:41] No está muy interesante. Y si como tú dices eran definitivamente la tecnología no estaba tan avanzada para ponerlo de alguna manera amable, pero no, qué interesante. Y bueno, se ve que tuviste un ejemplo de vida y de trabajo muy importante, tanto de tu papá como de tu mamá. Te acuerdas a lo mejor de alguna cosa como buen familia mexicana, de algo que te decía constantemente tu mamá o algún algo, algún recuerdo así que te ayudó y te impulsó para llegar hasta donde estás ahora.

[00:05:11] Pues mira este. Lo que yo veía mucho en casa era el trabajo. Este mi papá, como te decía, trabajaba de día, trabajaba de tarde, trabajaba de noche. Entonces creo que como dicen las acciones hablan más que mil palabras. Entonces el ejemplo que yo veía es que aún y después de largas horas de trabajo. Leía hasta las 2 3 de la mañana y los fines de semana, siempre haciendo actividades o manualidades con sus hijos. Entonces eso es algo que como dicen, son cosas que se que se viven en el día a día en tu casa y que te te dejan marcada, verdad? Entonces, y pues lo que siempre decía es la importancia de la educación, entonces eso es lo que lo que yo creo que realmente queda en mi DNA de esas épocas y

[00:06:01] De haber tocado una época muy interesante. No decías que trabajó para para Vitro y en ese momento me imagino que todavía era un monopolio. Yo trabajé para para Vitro, fue mi primer trabajo.

[00:06:10] Oye, quién no

[00:06:12] Dijiste que en alguna de sus

[00:06:14] Encuentros con el alcalde

[00:06:16] Yo estaba en medio plano, pero creo que le había tocado en Monterrey. En general, todas las industrias estaban realmente en un boom impresionante, creciendo rápidamente, agarrando su lugar en el mundo,

[00:06:31] Que era una epopeya industrial, o sea, Cemex, bitro, cervecería, etcétera. Todos los grandes emprendedores.

[00:06:41] Bueno, cuéntanos un poco sobre tu trayectoria profesional. Me dijiste un poco de tú, de tu infancia, cómo te fuiste encaminando hacia hacia la logística, hacia la calidad, hacia lo que haces ahora.

[00:06:53] Mira, pues yo estudié Ingeniería Química y me gradué del Tec con todas las ilusiones de mi padre y pues yo muy contenta. Este me apasionaba en las matemáticas, la química, la ingeniería y me graduó y digo no, pues yo quiero trabajar en una planta química y como estudié ingeniero químico y de sistemas, que es la parte de Haití, este en aquella época no hombre, era revolucionario. Entonces yo quería trabajar en la parte de control de procesos, de alguna manera era compaginar la página, digo la, la, la cuestión tecnológica con la cuestión de ingeniería química. Oye, pues no empiezo a buscar trabajo y con algo muy específico, este no. Más que nada, que no me querían contratar por ser mujer.

[00:07:37] En serio? Bueno, eso está muy interesante, pero antes de que entremos a esta parte, que es un pasito antes adelante, por qué no un pasito para atrás? Por qué ingeniería química y de sistemas? O sea que porque

[00:07:52] Esta es una muy buena pregunta. Es una buena pregunta y que va a llevarnos a una pata muy importante más adelante. Realmente este pues como a lo mejor algunos de tus radioescuchas, yo estaba en la prepa, no sabía que estudiar, lo único que yo sabía y que yo le decía a mi papá pues no sé que quiero estudiar, pero lo único que sé es que yo quiero estudiar algo en el que yo pueda ayudar a la gente, yo quiero ayudar a la gente, etc. Entonces me decía bueno, pues si quieres trabajar en esto tienes que trabajar algo como servicio social. Y dijo Pues ese tipo de carreras están aquí en México, en Monterrey no había tenido aceite a Ciudad de México, yo no estaba dispuesta en mi mente, no cabía cambiarme de residencia, irme a vivir sola, ir a trabajar. Y dije pues no, entonces realmente dije bueno, cuáles otras habilidades yo tengo que que a mí me gustaría explorar y revisando las carreras disponibles porque así era antes o ya

[00:08:50] No

[00:08:50] Es lo que uno sueña y es lo que hay. Sí, y este pues era me gustaba mucho las matemáticas, me iba bien, me gustaba mucho la química y me gustaba y tenía la inquietud de la parte de sistemas que era lo nuevo que venía de O cuando estaba en prepa fue cuando salieron las primeras Macs. Hay que ubicarnos en el tiempo. Yo sé que me veo de 25, pero bueno, este entonces este decidí yo estudiar la carrera de Ingeniero Químico de Sistemas y pues lo que yo me dije a mí misma por realmente este en cualquier carrera uno puede ayudar a los demás. Entonces dije bueno, vamos a explorar esa carrera. Y así fue como decidí entrar a la carrera de Ingeniero Químico y de sistemas y pues me fui apasionando en mi mente no cabía, claro que me

[00:09:37] Decía no tenía, pero no tenía todavía el conocimiento. Te fuiste enamorando de la carrera y de la profesión conforme fuiste?

[00:09:44] Sí, no, no me gustaba Matemáticas y química y sistemas y después me fui enamorando. Pero creo que si me decían oye Gladys, pues como que estás medio loca porque realmente está bien difícil. La carrera empieza x número de gente terminan bien pocos, no hay mujeres, no vas a conseguir trabajo. O sea, yo no creía que

[00:10:04] Solo abriendo brecha

[00:10:07] No hacía oídos sordos, o sea, como que no creía. Y luego ya cuando me gradué es cuando ya regresamos al punto, verdad? Entonces yo empezaba, veía como mis compañeros, digo algunos, hasta digo yo era de las más sobresalientes ahí en la carrera y veía como todos se iban encontrando trabajo y pues yo no y pues hasta que me armé de valor y preguntaba oye, pues por qué es que me faltaba verdad? Porque serán trabajos para recién egresados. Me dice no! Lo que pasa es que yo busca en plantas químicas y en la parte de control de procesos. Decía No, pues es que no hay uniformes de seguridad, no hay zapatos, no hay baños, no hay esto, no hay lo otro. Y yo me quedé por primera vez en mi vida me cayó el balde de agua fría. Entonces empecé a entender este porqué yo no encontraba trabajo.

[00:10:56] Y la diferencia tan grande que hoy todavía desgraciadamente existen muchos en todos los países y hay que hay que tratar de resolver,

[00:11:05] Claro, y luego ya han ido cambiando y ha ido cambiando bastante. Entonces en eso salió este el anuncio para trabajar en Mattel, en la planta de Monterrey como supervisora de laboratorio de pruebas de calidad. Entonces yo me acuerdo en ese entonces, pues el que es ahora mi esposo, que era mi novio, me dice mira Gladys, esta es una muy buena oportunidad, buscan ingenieros químicos y pues eso es algo que nos pasa mucho a las mujeres, de que queremos llenar el 100 por ciento los requisitos para atrevernos siquiera a levantar la mano a un proyecto o a un este, a un nuevo puesto le decía no, no cumplo más que el 50 por ciento, pues yo no voy a aplicar. Y luego volvió a insistir una semana o semanas. Oye, sigue saliendo, me volvió a insistir este y pues yo decía no, pues no, y luego le quitaban dos o tres cositas. Decía Bueno, ya cumplió el 70 por ciento, decía está bien, nada más voy a ir para complacerte, pero no porque cumpla, yo lo

[00:12:07] Repita más y mira nada más.

[00:12:10] Ahora no, pero esa es una muy buena lección, que yo hablo mucho con las chicas del inning, que ahorita platicamos un poquito de ese proyecto de apoyo a las mujeres ejecutivas. Entonces el el imagínate la oportunidad que se hubiera perdido cuando ahora ya tengo toda una trayectoria, oportunidad de trabajar en diferentes partes del mundo con diferentes roles, por el simple, sencillo, simple de que no cumplo todos los puntos. Entonces algo que que empecé a aprender desde muy temprana edad pero que se fue reforzando, haz de cuenta como cada dos o tres años es de que uno va a aprender en el camino, que es que tienes que salir de tu zona de confort para aprender y crecer y que hay que vencer los miedos para. Porque todo lo que buscas y todo lo que anhelas siempre va a estar ahí.

[00:13:00] Y más porque seguramente estabas como mucha gente aplicando y compitiendo con hombres que no tienen ni el 10 por ciento y dicen que tienen el 100 por ciento.

[00:13:09] Esa seguridad se las admiro y las admiro,

[00:13:14] Pero no creo que sea normal. Digo, no creo que sea necesariamente del sexo. Es un poco la sociedad y la cultura y lo que tú has dicho que nos ha llevado a creer que ciertos trabajos son para hombres y otros son para mujeres y es totalmente erróneo. Me da muchísimo gusto que rompiste, rompiste un estereotipo en la carrera y luego rompiste un estereotipo en el trabajo.

[00:13:37] Y luego ahí lo que sucedió es que ya después que iba progresando bien en la entrevista, que hoy es la parte que te digo, que lo aprendí a temprana edad, pero se ha ido reforzando a través de los años de que decía yo oye, pero yo Gladys, nunca he manejado gente y soy recién egresada, como que voy a tener 35 técnicos a mi cargo, o sea, no me cabía en mi cabeza. Y luego el motivo por el cual me querían contratar era para arrancar y construir el primer laboratorio químico de todo el sistema Mattel. Y yo decía pero yo. O sea, cómo entonces la falta de confianza, el que pues uno puede aprender en el camino, el vencer ese miedo y obviamente que era algo que yo anhelaba y que yo quería, entonces aún con el miedo decir sí, voy para adelante y pues gracias a Dios la verdad me fue muy, muy bien. Obviamente abrimos el laboratorio químico, hubo allí otras vicisitudes de términos

[00:14:37] De género,

[00:14:38] Me decían dónde está el como? Quien dice dónde está tu papá para negociar, verdad? Porque yo tenía 21 años en esas épocas, pero bueno, datos y hechos cambian en cinco minutos la conversación y hace que se centre en lo que se tiene que centrar y este. Y empecé después a crecer, a tener más áreas de responsabilidad dentro del área de calidad. Por eso estudié la Maestría en Calidad y Manufactura, porque yo quería ser suficientemente competente para el otro tiempo.

[00:15:07] Pasó de que acabaron obviamente contratando para ese puesto.

[00:15:12] Como entré un año a dos años, ya estaba yo teniendo otras áreas a mi cargo y cada año fui teniendo más áreas hasta que ya tenía todo lo que es el área de calidad. Y luego ahí viene la parte de en aquellas épocas era nuevo ISO 9000. De hecho no había compañías registradoras aquí en México.

[00:15:30] No fue la primera empresa que abrió el laboratorio de.

[00:15:35] De Monterrey, a nivel global, a nivel global y global, a nivel global. Y luego quién iba a decir oye, que

[00:15:41] Orgullo siendo también mexicanos y en México. Porque esa es la otra cara de la moneda que siempre uno se espera que se abra en Francia, o en Estados Unidos o en Alemania. La primera fue en México,

[00:15:52] Las cosas que hemos hecho orgullosamente mexicanas y de hecho yo fui la primera expatriado en Malasia de todo el sistema Mattel, Nigeria y allá está. No se sabía ni los procedimientos, pero bueno, hemos sabido brecha en muchas cosas y este y pues me dijeron ahora queremos que te hagas responsable de la implementación y ya es toda la planta de lo que es el sistema de calidad ISO 9000 y otra vez. Oye, yo no sé nada de estas. Yo no, nadie sabía ni quién era. No te preocupes, sabemos que puedes aprender, aprendes rápido y lo vas a lograr si esconde miedos y todos vamos para

[00:16:31] Que tenías también muy buenos jefes y mentores. Me imagino que porque por un lado estás tú siendo valiente y rompiendo estereotipos y paradigmas y y atreviéndose. Y por el otro lado tiene que haber la contraparte que te dé la oportunidad. Y eso ya se ve que Mattel tiene una cultura muy.

[00:16:46] Sí, estoy totalmente de acuerdo, muy, muy bendecida, porque aunque no había muchas mujeres en puestos de liderazgo, siempre tuve hombres que fueron rol models y que creyeron y me apoyaron para seguir creciendo dentro dentro de la organización y pues así fui escalando. Después vino otra apertura, una apertura de una planta y se seleccionaron a cuatro de los en esas épocas gerentes para promoverse a dirección, para abrir la planta. Y me dice a mí el general Narayen en Monterrey, en Monterrey, el general manager de la planta existente iba a ser el general manager de la nueva planta o un americano. Entonces me dice Oye Gladys, quiero que te unas al equipo, pero yo pensaba que en calidad porque yo venía de calidad, ya tenía mi maestría en calidad. También estudié la maestría en Desarrollo Organizacional porque me di cuenta

[00:17:41] Que yo era de esperar. Ya te saltaste ahí dos, tres partes. A qué hora? A qué estudiaste?

[00:17:45] Dos, y tuve tres hijos en el camino.

[00:17:49] Bueno, como tu papá, entonces te dormías a las 2 3 de la mañana, todos

[00:17:53] Los días en 4 horas dormía yo con 4

[00:17:55] Horas estás fresca? Si, ese es el secreto.

[00:17:58] Ya, ya, ya duermo más, ya duermo más este, pero más que nada la parte de desarrollo organizacional, porque yo venía de áreas muy técnicas. Entonces yo me di cuenta con el sistema de calidad ISO 9000, que tú puedes tener el mejor sistema de trabajo técnicamente hablando, pero si la gente no lo acepta como forma de vida y no como más trabajo, sino como mejor trabajo, empecé a entender la parte de los de la cultura de la gente. Me apasionó todo eso y creo que eso fue algo pues factores de éxito, verdad? Porque este el mezclar la parte humana con la parte técnica y la tecnología, pues realmente es un catalizador para los procesos de transformación y crecimiento en las organizaciones. Entonces por eso estudié la Maestría en Desarrollo Organizacional

[00:18:48] Y para también

[00:18:51] En la ADM, en la UNAM la estudié y en el TEC la de manufactura y calidad. Entonces el ya Dan Dan Gilbert que fue el que me habla y me dice oye, pues que queremos que seas parte del equipo. Yo súper feliz porque quería estar en la apertura de una nueva planta, porque yo lo veía como un laboratorio gigante. Poder poner en práctica todo lo mejor de lo mejor

[00:19:14] Es el perdón. Que te interrumpa nuevamente que en esta época Mattel está manufacturado. Qué son Barbies?

[00:19:20] Son muchas, pero no las Barbies y los Hot Wheels, que es parte del core business de materias manufactura en Asia. Por eso estuve allá trabajando

[00:19:28] Que era la planta de

[00:19:30] Que era la planta. Principalmente son los accesorios de Mattel para la Barbie, como las campers. El juguete número uno a nivel mundial se produce orgullosamente en Monterrey, que es la Barbie Dream House. Eso esos fueron hechos 100 por ciento en Monterrey para el mundo entero. Así que si

[00:19:49] Divertido como mujer trabajar en una empresa que realmente su primer producto es bueno, tienes los coches pero tienes también a las Barbies. Creo que

[00:19:56] Sí. Es un ambiente

[00:19:57] Divertido y muy divertido para ti.

[00:20:00] No, yo desde que pisé la planta yo dije aquí pertenezco porque rodeada de juguetes este en la parte de calidad. Pues ver la funcionalidad, la durabilidad, los riesgos de seguridad y saber que por cada pieza de juguete lleva felicidad a un hogar.

[00:20:18] Oye y tus hijos que

[00:20:21] Todos los juguetes habidos y por haber y jugaban con las cajas

[00:20:26] Como todo, como todos los niños del mundo,

[00:20:28] Si jugaban con las cajas de los juguetes, entonces que me dice mi? Me dice Gladys, pero queremos que seas la directora de Materiales y luego yo pues en Choco, porque yo decía

[00:20:41] Lo único que no habías estudiado era

[00:20:44] De planeación de la producción, el Master Planning en Desarrollo, Proveedores, Import Export, Control de almacenes de embarques,

[00:20:57] Elogies totalmente otra dimensión. Yo me

[00:21:00] Quedé. O sea, pensé que hasta se había equivocado. Y yo pues sí, soy de calidad y me estás ofreciendo el puesto a dirección de materiales. Y le dije a ver, obviamente que yo súper feliz de ser parte del equipo y de arrancar. Y claro que quería estar ahí, pero le digo este Dan. Yo toda mi experiencia es en calidad y esta es una nueva área y es un arranque de planta este lío. Estás consciente que pues no tengo la experiencia para hacer eso. Y me dijo Gladys algo bien importante que necesito que tú tengas bien claro. Yo puedo ir afuera al mercado y conseguir en un abrir y cerrar de ojos, pues a lo mejor cien personas que tienen la preparación para hacer este el trabajo que estamos buscando. Pero para mí lo más importante es dos cosas es que tengan el liderazgo y que hagan que las cosas sucedan, o si lo quieres ver como una liderazgo que haga que las cosas sucedan y no es fácil de conseguir. Además, pues a lo largo de tu trayectoria tú has demostrado que eres una persona que aprende y aprende rápido. Sí, entonces pues ya con eso que me dijeron, pues di con todo y los temores. Y aparte, no te preocupes, vamos a tener un año para entrenarte. Entonces pues ya con esas cuestiones, pues vamos para adelante con todo y temores y todo. Y pues ahí empecé la parte. Por eso estudié también la parte de en Thunderbird, en Arizona, la maestría en International Business e interactuar

[00:22:40] Con parte de esta capacidad, etc. en el año.

[00:22:44] Sí, y ahí empecé a abrirme en la parte de negociaciones internacionales, la cadena logística, el commodity management. Tú sabes bien porque tú estás en ese ramo, es inmenso, pues todo lo que tienes que aprender en la cadena de suministro de McEwen. Pero me apasioné el haber traído el sombrero uno de ingeniería, el 2, el de calidad. Tres, el de Organization and Development, pues fue una bomba exitosa. Por qué? Porque cuando vas a negociar y buscar oportunidades con los proveedores, yo me metí a conocer más de 100 procesos. Entonces es más fácil identificar las oportunidades para reducir costos, negociar mejor y asegurar la calidad y exigir la calidad que se buscaba. Entonces todo es en out. Este pues, me ayudó muchísimo,

[00:23:42] Muchísimo

[00:23:43] Para ser una mejor negociadora, para asegurar que las innovaciones o reducciones de costo estén no mermar a la calidad y la seguridad. Y si obtuviéramos este, pues los beneficios de costo que que necesitaba la compañía y obviamente poner en práctica todo lo que en ese entonces estaba en boga de que el canvas directo line, este BMI, este todo de proveedores este y empezar a acercar proveedores que se vinieran a relocalizar a México.

[00:24:19] Qué interesante! Está muy muy completo tu totalmente una escuela, una maestría en cadenas de suministro. Qué interesante! Y abrieron, abren la planta exitosamente, me imagino nos

[00:24:32] Fue muy bien. Y esta planta y que también es así como información

[00:24:36] Hay en ese momento, porque

[00:24:39] Había mucho talento emprendedor de nuestros principales. El principal competidor es Hasbro y Lego son los principales este. Pero sin embargo en Estados Unidos pues somos el número uno desde hace miles de años y pues de los eh ya ahorita Lego anda muy bien, pero a nivel mundial por mucho tiempo como número jugador número uno en la industria juguetes este más que nada calidad, seguridad y pues la innovación en los productos y lo que nosotros fabricamos o la razón de de esa nueva planta porque era una nueva planta en México era traernos la operación de Estados Unidos. Me tocó muchas transferencias, muchas aperturas, integraciones de nuevas operaciones y actividades de new sharing o de localización de proveedores. Este en esta época era la manufactura de Power Wheels. Power Wheels es una de nuestras. Marcas también icónicas, los jeeps desmontables eléctricos y es como la industria automotriz en la industria del juguete. De hecho, muchos de nuestros protocolos y compartiamos hasta proveedores con la industria automotriz. Dentro de la industria del juguete también están los protocolos de la industria de alimentos, porque tenemos por ejemplo Piqueras que tienen que ser FDA, cosméticos, las telas, lo que es vestido. Entonces mucha gente dice ah, son juguetes, pero realmente el protocolo de un juguete es bastante alto porque va diseñado a la persona más vulnerable, que es un niño o un bebé, que no solamente va a usar si no va a abusar del producto. Y ese producto, después de ser porque hacemos programas de caída, de estirones, etc. tiene que continuar siendo seguro aún y después del abuso y más los protocolos adicionales que tenemos que meter según el tipo de producto. Entonces la razón de abrir esa planta era la de la industria automotriz. En la industria del juguete que es está ruinas del mundo se fabrican aquí en Monterrey y pues se van a exportación.

[00:26:47] Hasta la fecha se siguen fabricando Narayen,

[00:26:49] Hasta hoy en día se siguen. La razón por la cual también estamos aquí es porque nuestro principal mercado es Estados Unidos y Canadá en Power Wheels. Y pues la cercanía y estás hablando del tamaño del producto, pues prácticamente es un refrigerador. Son productos muy muy grandes. Entonces tú sabes, el costo de fletes y transporte es imposible traerlo de Asia y después de ahí es de lo que vino. Es bueno, hay allí un momento histórico, verdad? En la historia de la industria del juguete de Mattel, muy conocido por los medios, en el 2007 tuvimos uno de los rincones más fuertes de la historia de de de. Se encontró en uno de los carritos de plomo y este. Pero fue en un monitoreo de los carritos Goodwill, en un monitoreo que se hizo en nuestros propios laboratorios y este ahí. Yo estaba en el área de Supply Change, en la apertura de la planta. Yo estaba acá en México y esto estaba sucediendo en Asia y este nosotros tenemos los esquemas de manufactura, aún es con proveedores que fabrican el producto terminado y otros con nuestras propias plantas que fabrican el corvinas de mate. Entonces este pues se encuentra. Eso fue un record voluntario

[00:28:11] En el lado del business o fue en el

[00:28:13] Que fue en el año del proveedor proveedor proveedor? Lo que sucedió fue que se hizo una subcontratación que no era permitida

[00:28:22] Y ahí es donde la calidad, el control de calidad se movió un

[00:28:25] Poco. Sí, entonces ahí empezamos. Este se hizo el record voluntario, nosotros mismos reconocimos la situación este se recolectaron todos los de

[00:28:38] Una empresa por todo lo que me has contado, con una cultura muy muy fuerte, con valores muy bien establecidos para

[00:28:46] Principales integridad inquebrantable. Y ahí fue en esos momentos donde la vimos en acción, porque muchas de las empresas lo que no te

[00:28:55] Cuesta evitarlas

[00:28:56] No pueden predicar las pero no realmente ejercerlas porque puedes perder hasta el negocio con una situación de este tipo. Pero todo momento se comunicó a todos los empleados de Mattel lo que estaba sucediendo, lo que se estaba haciendo. De hecho en esa época, recalcando lo de integridad inquebrantable. Era la primera vez que Mattel estaba como en una nominada y por Forbes no por Fortune como una de las mejores empresas para trabajar. Normalmente se hace en el último cuarto el release, pero en el verano, como en junio, más o menos pasa esto. Inclusive fue también otro momento histórico en que dicen oye, pues deberían estar, mátelo. No se lo cuestionaron y se decidieron hacer algo que normalmente no se hace es volver a aplicar todas las encuestas. Entonces, para ver si continuamos en ese listado de los top 100, entonces pone que eso pasó en el segundo cuarto y como por el tercer cuarto y ya estaban haciendo las encuestas y pues qué crees que pasó? Quedamos o no quedamos este? Pues no solamente quedamos, mejoramos hasta el lugar. Ya no me acuerdo los números ni nada.

[00:30:07] Es impresionante lo que muchas otras empresas a lo mejor lo habían querido esconder o hubieran querido darle la vuelta, o sea, siendo responsable, honesto y bueno con la política de integridad inquebrantable. Te ayudó al final de cuentas? Me dijeron que fue unos años difíciles, pero a final de cuentas tu imagen y la confianza que tenían tus clientes y tus proveedores de Mattel subió gracias a ser honesto. O sea, asumir la responsabilidad. Pero esto es lo que aprendimos de nuestros papás cuando teníamos cinco años. Básicamente no es nada del otro mundo, la verdad

[00:30:41] Tampoco correcto, pero son decisiones muy difícil solo cuando hay cuestiones financieras de por medio.

[00:30:47] Y totalmente de acuerdo.

[00:30:49] Y de repente, impresionante. Sin embargo, todos los empleados, pues nos sentimos muy orgullosos y se reflejó en en ese. En ese número y este y yo en un proceso de reconstrucción del sistema de calidad global. Yo estaba en materiales, en el arranque, en la planta. Entonces ahí yo empecé a trabajar a nivel global con todas las plantas de Mattel, implementando este pues procesos de mejora y de robustecimiento del sistema en

[00:31:16] Otra posición o la

[00:31:18] Otra. Moví, me moví de una posición local de dirección de materiales a una posición global de dirección senior global de Building de calidad. Y posteriormente trabajé un par de años en eso y después tuve la responsabilidad de calidad. Ya me quedé un poco más en calidad, en en calidad. En América tenía la responsabilidad de las plantas de México, de Canadá, que se había adquirido mega blocks. Es este la competencia de LEGO, la integración, ponerla en sistema de calidad ISO 9000, construir laboratorios. Trabajé mucho tiempo en Brasil, me la pasaba entre México, Brasil y Canadá, como que dos semanas en cada lugar. En Brasil era desarrollo de proveedores de producto terminado por por el lado de calidad, el desarrollar el mercado en aquella, en aquella región y este y también en esa época, como también parte del proceso de rehabilitan. Ya se me empiezan ahí a cruzar de las fechas, pero más o menos hay más o menos este. También me dieron la responsabilidad de los laboratorios a nivel global y los laboratorios a nivel global, pues estamos hablando de dos que pertenecen a Mattel y 40 que son en los del esquema de manufactura subcontratada. Entonces, en cincuenta y dos laboratorios de pruebas, ahora sin mecánicas, eléctricas, químicas, apertura de laboratorios y lo más importante es la transformación en cuanto a implementar el sistema de calidad ISO diecisiete 025, que es más estricto que el nueve mil para cuestiones de pruebas de desarrollo de pruebas y asegurar la estandarización al 100 en cualquier laboratorio del mundo y la integración tecnológica digital transformation en esas épocas de con la implementación de un sistema que le llamamos limp, que es Laboratorio Integridad Management System para tener total visibilidad de la operación en cualquier momento. Inclusive los equipos de prueba están interconectados.

[00:33:23] No era todavía desde Monterrey.

[00:33:26] Me imagino que bueno, aquí estaba, si no, no estaba en Monterrey, pero era un puesto, la verdad. Por ejemplo, en mi caso yo tengo muchísimos años, nada que ver con la pandemia entre trabajo remotos de trabajos globales, virtuales y multiculturales desde hace siglos, verdad? Entonces esto yo lo estaba manejando desde la operación de Monterrey como base en Monterrey y ya después viene la relocalización. Digamos que traía.

[00:33:54] Cuéntanos un poco porque eso está muy interesante en cómo acabaste en Malasia?

[00:33:59] Sí, entonces estaba yo trabajando con los laboratorios y con América. Entonces pues de alguna manera, pues se logró la integración de la planta de Canadá, se logró el desarrollo del mercado de Brasil, ya teníamos más estable la parte del RI Building global, la parte de la integración de los laboratorios. Entonces viene la oportunidad de trabajar para el core business de Mattel, que son Barbie Hot Wheels, que como te comentaba, la manufactura está en Indonesia, Malasia, Tailandia y China. Entonces la base este tenía que ser en Malasia. Entonces yo con mi familia, mis tres hijos, mi esposo y yo en el 2015 a dos mil, casi veinte, este a finales de 2019 más o menos este estuvimos viviendo y trabajando, estudiando en en Malasia, en una isla que se llama Penang, que ahí es donde está una de las plantas y pues ahí era desde desde la perspectiva de de calidad, pero siempre he estado muy de cerca, pues todo lo que es manufactura.

[00:35:02] Qué interesante estar en un país

[00:35:05] Sumamente

[00:35:06] Remoto, muy diferente, o sea no es

[00:35:08] Y pues continua el mismo como quiera continuar. Lo mismo que te decía yo lo que aprendí desde muy joven nada más se ha ido reforzando en el sentido de que oye Gladys, pues sabes. Ahora es otro país, verdad? Entonces, y no solamente es otro país, es otro mundo literal, porque son otra cultura, es una cultura musulmana. Este y este se reza cinco veces al día. Es un país muy, muy devoto. Este, pues, las mujeres visten con su con su burka. De hecho, en las instalaciones operativas nosotros tenemos como se ven como salones de baile, así gigantes, porque se hacen paros programados de aproximadamente 15 minutos en el que parte del protocolo es me lavo los pies e paso a la sala a hacer mis rezos mirando a la Meca. Este se separa en hombres de mujeres. Entonces tienes que tener un salón muy grande para hombres, un salón muy grande para mujeres. O sea, tienes que adaptar los procesos de manufactura a las costumbres y respetarlas. Este practican el Ramadán. Las comidas también son diferentes. Es es. Lleva todo un protocolo de rezo y de cómo se se mata al animal para que no sufra. Entonces la comida es diferente. También ellos este pues no comen el puerco este. También tienen el proceso del Ramadán que dura 40 días donde se hace ayuno por durante el día no comes, no tomas ni agua y nada más. En la noche puedes ingerir alimentos. Este mezquitas hay como los Starbucks en Nueva York en cada esquina son hermosas porque ellos rezan antes del amanecer, como al mediodía, al atardecer y después en el anochecer a uno o dos, o sea, antes de amanecer, luego como a las doce, luego en la tarde y luego en la noche. Algo así son. Son cinco veces al día, cinco veces al día

[00:37:18] Cual perdón que te vuelva a interrumpir, pero todas estas cosas que son bastante interesantes que has platicado. Cuál fue la que te costó más trabajo? Adaptarte. Me dijeron que todo esto era nuevo para ti y tu familia. Cuenta de

[00:37:31] Que es

[00:37:33] Una experiencia increíble e inolvidable también

[00:37:35] Y obviamente que es tanto para mi familia como para mí, pues realmente era desde comer. Era totalmente diferente a los alimentos de la máquina que venden aquí, no sabe como la de allá no usan. Por ejemplo, no es que usen palillos, Malasia es diferente, no es China. A veces confunden Malasia con China. El sudeste asiático es otro, otra gente de otra zona. Ellos en lugar de usar cuchillo y tenedor, se usan cuchara y tenedor. Entonces de ahí a como partir la carne usando cuchara y tenedor. Desde ahí empieza todo. Y los baños, digo, hay baños normales, pero también son los baños. Pues de pozo verdad? Este e inclusive en lugares bien, entonces este y luego la alimentación, la socialización. Tú no puedes. Por ejemplo, mi esposo, pues el que le da la mano para saludar a una mujer pues lo va a dejar con la mano estirada de lado. No se puede, no se puede tocar la realidad de la pregunta que me haces este. Nosotros lo disfrutamos enormemente. Yo creo que hay gente que no se adapta tan fácil o no tiene tanta flexibilidad. Nosotros adoramos la diversidad este. Yo siento que por esa experiencia tanto mis hijos como mi esposo como yo, este el, el ver que hay y a tan joven edad estar expuesto a diferentes formas de pensar. La tolerancia

[00:39:10] Es una enseñanza de por vida que le pudiste ofrecer a tu familia

[00:39:14] Y tu visión cambia. Desde mi perspectiva es de los líderes, no nacen, se hacen y como se hacen es a través de la diversidad de experiencias, a través de la diversidad, en las formas de pensar y en la inclusión de esas, de esas eres mejor líder porque tienes mayor versatilidad e inclusive a eso que llaman la intuición del líder. Pues bien, de todo eso que lleva detrás de ti, entonces este lo que nosotros vimos es que en Malasia en particular este como fue colonia inglesa, aparte de hablar el malayo, se habla el inglés, que con eso somos muy afortunados y hay escuelas británicas que era donde pueden estudiar mis hijos, pero había muchísimas nacionalidades por si solo. Malasia son el son tres culturas, es la malaya que es como un 70 por ciento o como un 20 por ciento son los chinos malayos y el 10 por ciento más o menos son los indios, entonces. Una vez en el día a día ya parece sin los expatriados. Tú ya ves en una mesa de discusión, en una mesa de negociación, tú puedes ver a un malayo, a un indio y a un chino. Este en esa diversidad la diversidad enriquece esto mucho la toma de decisiones, la innovación, la creatividad y apoya pues el trabajo en equipo. Si sabes manejar la inclusión y adicional, pues hay otras culturas porque hay muchos expatriados, principalmente de Australia, Inglaterra en Nueva Zelanda. Este son de los principales países que hay en otros. No sabía ni nos ubicaban porque no había mexicanos,

[00:41:04] No el único.

[00:41:05] Me imagino que a mí me decían que si era rusa lo creo por el acento, no sé.

[00:41:11] Oye, pues qué? Que qué increíble experiencia, no? Más allá de la parte profesional y más allá de todo lo que han de haber aprendido, yo creo que la experiencia humana que tuvieron tú y tu familia es envidiable. Imagino que, como tú decías, no es algo que busque. Los acompañará para toda su para toda su vida. No es algo. Y ahí estuviste hasta el 2019 entonces o hasta cuándo?

[00:41:35] Sí, sí, como el 2016, en el 2019

[00:41:37] Y todo esto. Eras la vicepresidenta global de

[00:41:39] Calidad hoy era este vicepresidenta de calidad manejando el sudeste asiático. También está

[00:41:47] Claro que según la normativa en India y

[00:41:50] Bueno, ahí, ahí lo que empezó a suceder también hay que ubicarnos en Supply Change, siempre está inherente en todo esto. Tenemos que ver que una de las principales tendencias en Supply Change por diferentes motivos en el pasado era acuérdate que estuvo muy fuerte, pues la guerra política de aranceles entre China y Estados Unidos. Entonces muchas empresas globales han estado buscando diversificar su manufactura a otros países fuera de China, pues para poder sopesar esas esas restricciones. Entonces, cuando yo estaba allá, pues me tocó la parte de apoyar desde la perspectiva de calidad que llevaba un fuerte control en la parte del desarrollo del proveedor a ser un proveedor fuerte a los estándares de Mattel, que a veces en los países de tercer mundo no necesariamente estándares

[00:42:47] Son estándares muy

[00:42:48] Muy hoy que hay que llevarlos de la mano. Entonces se decide, como muchas otras empresas a nivel global, empezar a diversificar en India y Vietnam. Entonces ahí pues me tocó también colaborar en esa parte y después con todo lo del COBIT, este sigue reafirmando más para la industria global, el estar más cerca de tu mercado y buscar la forma de localizar para evitar disrupciones en la cadena de suministro. Entonces, por eso también ahorita uno de los proyectos en los que estoy trabajando es le llamamos Mentoring Activities o localización de proveedores en México y Sudamérica. De manufactura de juguetes, verdad? Porque nuestro mercado principal está en Estados Unidos. Entonces estamos buscando pues estar más cerca de nuestro mercado principal y este y pues por eso precisamente regreso de Malasia a México este. Y ahí estuve un año trabajando en una asignación especial aquí en Monterrey, porque ya me cambié de sombrero, ya me fui ahora a Manufactura e Ingeniería de operaciones, otra vez Supply Chain y todo eso. Este porque lo que estamos buscando. Bueno, que seguimos trabajando en eso, pero ya va muy adelantado, es consolidar un negocio de manufactura en Monterrey en el cual se localice manufactura de China, Canadá y otras plantas de México, para que este mega site sea el que produce y envía todo a Estados Unidos. Entonces puede trabajar prácticamente para mí no existía la pandemia. Fue este cuatro porque era un reto de crecer la planta, pues de mil gentes a 4000 e transferencia de productos.

[00:44:41] Eso ya pasó. Eso es en lo que se trata en

[00:44:43] El 2020 2020.

[00:44:46] Ya todo eso está hecho así. Mega El Mega soy de manufactura y

[00:44:50] Está ahorita todavía funcionando. Faltaba una parte y ya está y falta nada más de integrar la parte de Canadá ya está funcionando y este y pues terminar esa asignación de transferir la parte de México de parte de integrarlo de México. Lo de lo de Asia es de asegurar el crecimiento, los indicadores y pues sí, fue un orgullo bastante grande porque ha hecho cuando se ra en diciembre este que es lo que más me. Las satisfacciones de que viene de la misma gente. Estás hablando de técnicos, líderes, supervisores, de que me pidieron que pusiera las huellas de mis manos en. Obviamente no es algo común que pase en manufactura porque pues la transformación que se había logrado en cuanto a las mejoras y el crecimiento y pues esta planta ya tenía, ya había sido anunciado en los medios de que iba a cerrar. Pero luego vino este, pues el cambio radical

[00:45:50] No sólo cerró, sino se convirtió en la planta más.

[00:45:52] Entonces la gente estaba muy agradecida por mantener su trabajo y no solamente por mantenerlo, sino que se creció y se dio más trabajo a más gente. Y pues ahorita regreso a Corporativo, aunque físicamente como estoy en trabajo remoto estoy en Monterrey, pero trabajo dese cuenta de que estoy en Los Ángeles, este en el área de calidad, pero ahorita estoy en varios proyectos muy interesantes en la transformación digital en Taiwán, pero en la parte de calidad estamos trabajando en la implementación de una le llamamos y Hommes que es Enterprise Quality Management System, que es para integrar todas las operaciones en una sola plataforma digital. Eso es un proyecto bastante ambicioso y obviamente transformacional. Y también pues como te comentaba otro de los proyectos, todo va encaminado si lo ligamos a lo que tú y yo andamos, que es Global Supply Chain, lo que vemos de las tendencias y de las estrategias uno es pues en general no nada más en Supply Chains es la transformación digital en general. La otra es la parte de la localización este, ya sea de materias primas o de producto terminado. Pues eso, estoy trabajando ahorita en México y en Sudamérica y en Haití estamos trabajando en eso. La parte de buscar la sustentabilidad en los proyectos que estoy trabajando, pues es ya manufacturar con bio resinas y 100 por ciento reciclables, pues la mayor parte de los componentes buscando el que la mayor parte de los componentes sean 100 por ciento reciclables. La sustentabilidad que es lo otro que viene, este ya sabes que ahora es ya de hecho no nos llamamos supply chencha, ahora hay que value, change y value.

[00:47:41] Bueno, ahora si a todo el mundo. Ahora si. Después de la pandemia ya todo el mundo valora un poco más lo que se hacía en la cadena de suministro,

[00:47:48] No ya desde cuenta jugadores claves y al corazón. Entonces tú sabes que ahora en la cadena de suministro tienes que hacer más. Qué quiere decir esto? Por ejemplo, si tú tienes un centro de distribución que pues antes nada más distribuía los productos, ahora hacen valor agregado. O sea, se convierten en un value change. Y ahí también hay networks con los que tienes que colaborar, porque no necesariamente tienes el nou de todo para hacer que las cosas sucedan. Porque qué pasa con el cliente? Todo para ayer.

[00:48:21] Se impaciencias han sido mucho mayores.

[00:48:24] Producto es el servicio, es la experiencia, es el entretenimiento. Nosotros ya no vendemos juguetes, simplemente vendemos películas, vendemos videogames, vendemos experiencias. En los retailers este tuvimos que hacer pues todo un proceso de transformación que muchas empresas lo están haciendo. Entonces también parte de lo que estoy trabajando es esos centros de distribución. Ahora son cuestiones de valor agregado, que también llevar un sistema de

[00:48:52] Nunca te vas a aburrir, me parece. Creo que tienes un trabajo y has tenido una carrera y una trayectoria admirable y ejemplar, sumamente destacada. Y me siento por un lado orgulloso de poder entrevistar a una mexicana este con tanto talento. La verdad creo que es algo importante el destacar que México y los mexicanos y los latinoamericanos y Hispanoamérica, todas las personas de Latinoamérica tienen un potencial enorme y tiene un rol muy importante en las cadenas de suministro y en muchas otras industrias en el mundo. Entonces, muchísimas gracias. Voy a cambiar rápido de tema porque lo podríamos platicar otras horas, tres o 4 horas y de hecho a lo mejor vale la pena hacer otra entrevista si tú estás dispuesta. Para mí ha sido un gran, gran honor y un gusto, como te decía. Pero si quiero dos cosas puntuales. Una, si tú te tuvieras que dar un consejo a ti misma 20 años en el pasado, cuál sería? Qué de toda esta trayectoria tan exitosa que has tenido? Qué consejo te darías a ti misma?

[00:50:05] Ahora, mira, yo el consejo que me daría a mí misma a lo mejor suena muy simple, pero te lo voy a platicar. Es que es. Es tener en la mente que no importa los retos, todo va a estar bien al final de cuentas. Con que me refiero con esto yo lo tomo como veo la la vida es que tenemos muchas metas, tanto en lo personal como en lo profesional, para mi están en la punta de las montañas y pues el hecho de de subir a esa montaña pues ya es un trabajo y un esfuerzo significativo para lograr alcanzar esa meta. Sin embargo, yo no lo veo como una línea recta al llegar a esa meta, yo lo veo como un zigzag que tiene caídas y subidas, caídas y subidas y cada una de esas caídas son situaciones que nos pasan, son retos que yo veo como mandatorio que tenemos que vivir, pero en ese momento no los entendemos, en ese momento nos sentimos que nos ahogamos, que nos asfixiamos. A veces inclusive tenemos que irnos a rastras para poder superar esos retos, llámese una pérdida de un ser querido, una enfermedad, un trabajo. Digo, no hablamos nada de la parte personal, pero obviamente yo tuve fuertes retos en que yo me sentía que nunca iba a salir y el que te preguntas para qué? Y al paso de los años lo descubres. El para qué no es inmediato.

[00:51:31] Este tuve la pérdida de un bebé, tuve cáncer, sobrevivió un incendio. Entonces hay momentos bien difíciles que te tumban, que te tumban, que sientes que ya no puedes más. Pero viéndolo yo en retrospectiva, de cada uno de esos momentos y de esos retos, hay un aprendizaje y es un superpoder que tienes que adquirir, porque si no tienes ese su superpoder en la siguiente etapa no lo vas a lograr. Necesitas el ir construyendo esa resiliencia o esas experiencias que tuviste que vivir con cada reto para que puedas superar de mejor manera en los siguientes retos. Y así hasta que tú llegas a tu meta. Pero siempre debes de tener la tranquilidad que cuesta creerlo. Este yo ya nada más por la edad y por las experiencias, te lo puedo decir, que a veces me tomó hasta cinco, ocho años el entender porque paso a pero era para que sucediera ve en cinco años después y para que yo realmente estuviera lista, porque si eso me hubiera pasado hace cinco años, yo no hubiera estado lista. Entonces este es el universo, es sabio este. Tenemos que tener esa confianza, este, pues los retos ahí van a estar, es parte de la vida, hay que afrontarlos y hay que salir adelante. Y muchas veces ahí lo voy a ligar con algo que hemos estado platicando a lo largo de la charla, el día

[00:52:57] Antes, antes que lo lleguemos, porque de hecho esa era mi segunda pregunta me ganaste? Y la pregunta pero las quiero. Pues quiero agradecerte por por la apertura que has tenido conmigo el día de hoy y por la fuerza y tu carácter y o sea, se nota que se nota que has sido muy exitosa, se nota que te ha costado trabajo, no ha sido fácil y nuevamente te interrumpimos para decirte que gracias. Creo que esta ha sido una muy buena entrevista. Estoy seguro que muchas personas nos están escuchando y no solo les vas a dar información adicional sobre las cadenas de suministro, sino un poco una inspiración para la vida diaria de cada uno de nosotros y el ejemplo a seguir para muchas mujeres y muchas niñas. No, gracias. Y ahora si la segunda parte es sencilla, tú dinos porque es lo que más me gusta a mí también la deseo de dar a los otros y la forma que has ayudado.

[00:53:55] Tu involucramiento en lo que iba a complementar de lo de los retos y de las montañas era más que nada que pues a veces en esos zigzags que vas en tu camino hacia tu meta, este cuando dices uno bueno que son mandatorio, son aprendizajes y me van a ayudar. Pero a la vez hay una parte que hemos hablado a lo largo de toda la conversación, que es vencer el miedo, salir de tu zona de confort y que a veces tienes que vencer esos miedos en esas, en esos baches, porque si no, a lo mejor te quedas estancada y nunca vas a subir, ni siquiera vas a vivir la experiencia de lo que tuviste que vivir y aprender para poder superar siguientes retos que viven en tu vida y para llegar a tu meta. Entonces necesitamos no quedarnos congelados y este y tener el coraje que yo sé que es más fácil decirlo que hacerlo, pero aún y con el miedo y temblando tus rodillas, hay que dar el paso, hay que dar el paso adelante este. Pero bueno, creo que ahora sí que

[00:54:57] La tengo y de hecho estoy viendo un poco y quiero obviamente ser muy respetuoso con tu tiempo también este te iba a ofrecer mejor. Que tal si nos dices un poco de este otro tema que es tu pasión por dar a los demás, por ayudar a los demás y toda la ayuda que tuviste al Hospital Lenín cuando esté en Malasia. Todo eso se me hace sumamente interesante, me gustaría, si te parece bien, obviamente, y no te quiero comprometer tampoco en vivo, como que ya podemos editarlo siempre, pero te parecería agendar otra tiempo sólo para hablar de eso? Pero ahorita tampoco un poco, un poco es un poco tu tu parte esta que integra de quien eres como persona. Y yo creo que refleja también un poco la cultura y valores de Mattel de ayudar a los demás, porque eso a mí me parece muy muy impresionante también y algo que vale la pena mencionar

[00:55:51] Y será un placer regresar contigo.

[00:55:54] Hagamos eso porque sé que se está. Démosle un poco de tiempo, dinos qué es lo que has hecho para ayudar a los demás con las organizaciones que tanto te apasionan y también lo que ha hecho Mattel para ayudar a la gente en general. Y hablemos. Aprendemos otra llamada para contar sólo de ese tema.

[00:56:11] Claro que sí. Y ese tema va a ir ligado con algo que mencionamos aquí al inicio. Recuerdan que en un inicio dije a mi padre es que yo quiero estudiar algo en el que yo ayude a la gente. Entonces de ahí nace el que también he aprendido que lo que sea que llames propósito de tu vida, tarde que temprano te encuentra y tarde que temprano se cristalizan. Pero hay que estar atento a las señales que te manda el universo. A lo mejor en mi caso fue sobrevivir a un incendio en el que decidí dejar de ser indiferente este y ayudar más en especial a mujeres, jovencitas y niños, que son las causas que percibo ahorita y que vamos a platicar un poquito más a detalle de las cosas tan interesantes que están haciendo. Y también pues cómo pueden a lo mejor ustedes iniciar sus propios proyectos de cambio y de transformación y de trascender. Creo que es la mejor forma que tenemos nosotros los seres humanos de realmente trascender y realizar un propósito en esta vida.

[00:57:15] Pues muchísimas gracias. Nuevamente vamos a agendar esta llamada que muchos, muchos van a querer escuchar para todos los que nos están escuchando nueva. Nuevamente mi nombre es Enrique Álvarez, esto ha sido un episodio más de Supply Chain Now en español y un gran gusto platicar con Gladys Araujo y como ya se comprometió en vivo será mínimo. Tendremos otro episodio más detallado a que nos platique un poco más su experiencia después del incendio y cómo su vida profesional y personal, me imagino, se fue transformando para ayudar a muchas otras personas. Gladys Nuevamente muchísimas gracias, un honor y un placer. Cuentas con todo mi apoyo y gracias por el gran ejemplo que nos has dado.

[00:58:01] Gracias a ti.

Episode Summary

In this episode of Supply Chain Now in Spanish, host Enrique Alvarez welcomes Gladis Araujo, the VP of Global Quality for Mattel, to the show. Listen to this leadership dynamo, as she discusses her life-long love of learning, her engineering and quality background, and her extraordinary career. Learn from Gladis as she shares her message of being brave, breaking gender stereotypes and the importance of allyship and mentorship. Listen up!

Episode Transcript

[00:00:37] Good morning and welcome to another episode of Supply Chain Now. My name is Enrique Alvarez and I have the pleasure and pleasure of interviewing a woman who has made a very good career, not only at Mattel, but with many other organizations and I have the pleasure of talking with her. Mattel’s Vice President of Global Quality, Gladys Araujo. How are you? Good morning.

[00:01:01] Well, I am very happy to be here with you on your Play Change Now in Spanish. Thank you very much for the invitation, Enrique, my pleasure.

[00:01:10] The pleasure is all ours and well, based on what we were talking about before we started recording this show, I think we have a lot to talk about and it is a pleasure to have you here with us for all the people who are listening to us in Latin America and all over the world. If you like this kind of interviews and you like and are motivated by this kind of talks, be sure to subscribe. And well Gladys, let’s start a little bit with you. Tell us a little bit about your life. Where were you born? Where are you from?

[00:01:40] Of course it is. Look, I’m a regia, as they say here in Monterrey. I was born in Monterrey, Mexico, I was born here, I grew up here, I am the oldest of four siblings, I have one brother and three and two and two sisters. Tradition a traditional Mexican family is my dad, because he works full time, my mom dedicated to the home. My dad is a civil engineer and worked for more than 30 years in one of the industries here in vitro, but he always had thousands of jobs and was tireless to be able to support the family. As his career is a civil engineer and passionate about construction, he always had jobs outside of building schools, squares, bridges, buildings, houses, a little bit of everything as he says, and his lifelong dream and his purpose, because he did not say it to us, was to ensure that his four children would have a professional career and he was looking for and longed for it to be in a good institution. So all his work, all his savings, all his focus went into that. And something he mentioned a lot, that is, the best inheritance we can leave them is education. And from there, you also make your way. Another of the things that I learned, which is the seal that I carry to this day from my parents, especially from my dad, is to learn continuously in those times. Well, the truth is that it is not like today when there was internet, there was a bookstore on every corner, it is difficult to get books in English, etcetera, and the way it was done in those days was, I don’t know if you remember Enrique, or if it was your turn, they sold you from house to house and encyclopedias.

[00:03:35] I consulted the Salvat Encyclopedia and the Encyclopedia Britannica.

[00:03:39] And I want everything in very large collections of more than one hundred, two hundred books and I don’t know, everything.

[00:03:47] A heritage. It wasn’t whether it was really a strong buy, because they weren’t cheap, because

[00:03:53] This was a very, very heavy investment. But they believed very strongly in education, that the typical weekly payments or monthly payments and I don’t know, but it was a big investment and it was Christmas for me the day I got to my living room and saw the monster of boxes full of books and I can tell you that I practically read them all, from my childhood to my adolescence and what I learned is to love books. I learned that through books you live many lives and gain many experiences and from there I consider myself as they say in English On life long learning of continuous learning and so to this day.

[00:04:41] It is not very interesting. And yes as you say they were definitely the technology was not so advanced to put it in some kind way, but no, how interesting. And well, it is clear that you had a very important example of life and work, both from your father and your mother. Maybe you remember something like a good Mexican family, something that your mom constantly told you or something, some memory like that that helped you and pushed you to get to where you are now.

[00:05:11] Well, look at this one. What I saw a lot of at home was work. My father, as I was telling you, worked during the day, worked in the afternoon, worked at night. So I guess as they say actions speak louder than a thousand words. So the example I was seeing is that even after long hours of work. She would read until 2 3 in the morning and on weekends, always doing activities or crafts with her children. So this is something that, as they say, are things that you live day by day at home and that leave a mark on you, right? So, what I always said is the importance of education, so that’s what I think really remains in my DNA from those times and what I think is the most important thing in my DNA.

[00:06:01] Of having touched a very interesting era. You didn’t say he worked for Vitro and at that time I imagine it was still a monopoly. I worked for Vitro, it was my first job.

[00:06:10] Hey, who wouldn’t

[00:06:12] You said that in some of its

[00:06:14] Meetings with the mayor

[00:06:16] I was in the middle of it, but I think he had played in Monterrey. In general, all industries were really booming, growing rapidly, taking their place in the world,

[00:06:31] It was an industrial epic, that is, Cemex, bitro, brewery, etcetera. All great entrepreneurs.

[00:06:41] Well, tell us a little bit about your professional career. You told me a little about yourself, about your childhood, how you moved towards logistics, towards quality, towards what you do now.

[00:06:53] Look, I studied Chemical Engineering and I graduated from the Tec with all my father’s illusions and I was very happy. I was passionate about mathematics, chemistry, engineering and I graduated and I said no, I want to work in a chemical plant and since I studied chemical and systems engineering, which is the Haitian part, at that time I was not a man, it was revolutionary. So I wanted to work on the process control part, in a way it was to combine the page, I mean the, the, the, the technological issue with the chemical engineering issue. Hey, I don’t start looking for a job and with something very specific, not this one. Most of all, they didn’t want to hire me because I was a woman.

[00:07:37] Really? Well, that’s very interesting, but before we get to this part, which is a little step forward, why not a little step back? Why chemical and systems engineering? So because

[00:07:52] This is a very good question. It’s a good question and one that will lead us to a very important leg further down the line. Actually, like some of your listeners, I was in high school, I didn’t know what to study, the only thing I knew and the only thing I told my father was that I don’t know what I want to study, but the only thing I know is that I want to study something in which I can help people, I want to help people, etc. So I said to myself, well, if you want to work in this, you have to do something like social service. And he said Well, that kind of careers are here in Mexico, in Monterrey I had not had oil in Mexico City, I was not willing in my mind, I could not change my residence, go to live alone, go to work. And I said well no, so I really said well, what other skills do I have that I would like to explore and reviewing the available careers because that’s how it was before or already.

[00:08:50] No

[00:08:50] It’s what you dream of and it’s what you get. Yes, and this was because I really liked mathematics, I was doing well, I liked chemistry and I liked and had the concern for the systems part that was the new thing that came from O when I was in high school was when the first Macs came out. We must place ourselves in time. I know that I look 25, but well, I decided to study Chemical Systems Engineering and I told myself that in any career one can really help others. So I said well, let’s explore that career. And that’s how I decided to enter the career of Chemical and Systems Engineer and then I was passionate about it in my mind.

[00:09:37] He said he did not have, but he did not yet have the knowledge. Did you fall in love with the career and the profession as you went along?

[00:09:44] Yeah, no, I didn’t like math and chemistry and systems and then I fell in love. But I think that if they told me, hey Gladys, you’re kind of crazy because it’s really very difficult. The race starts with x number of people, very few finish, there are no women, you are not going to get a job. I mean, I didn’t think that

[00:10:04] Just breaking through

[00:10:07] He did not turn a deaf ear, that is, he did not believe. And then when I graduated, that’s when we got back to the point, right? Then I started, I saw how my classmates, I mean some of them, even I mean I was one of the most outstanding there in the career and I saw how everyone was finding a job and I didn’t and then I got the courage and I asked myself, hey, why is it that I was missing, right? Because they will be jobs for recent graduates. He says no! What happens is that I look in chemical plants and in the part of process control. He said No, because there are no security uniforms, no shoes, no bathrooms, no this, no that. And I stayed for the first time in my life I was hit with a bucket of cold water. Then I began to understand why I couldn’t find a job.

[00:10:56] And the difference is so great that today, unfortunately, there are still many in all countries and we must try to resolve it,

[00:11:05] Of course, and then they have been changing and it has been changing a lot. So that’s when this advertisement came out to work at Mattel, in the Monterrey plant as a quality testing lab supervisor. Then I remember back then, the man who is now my husband, who was my boyfriend, told me look Gladys, this is a very good opportunity, they are looking for chemical engineers and that is something that happens a lot to us women, we want to meet 100 percent of the requirements to dare to even raise our hands to a project or to a new position, I said no, I do not meet more than 50 percent, I am not going to apply. And then he insisted again for a week or weeks. Hey, he keeps coming out, he insisted again and I said no, well no, and then they took two or three little things away from him. I was saying Well, you have already fulfilled 70 percent, I was saying okay, I’m just going to go to please you, but not because I’m fulfilling my 70 percent, I’m just going to go to please you, but not because I’m fulfilling my 70 percent.

[00:12:07] Repeat more and look no further.

[00:12:10] Not now, but that is a very good lesson, which I talk about a lot with the girls in the inning, and we are just now talking a little bit about this project to support women executives. So imagine the opportunity that would have been lost when I now have a whole trajectory, an opportunity to work in different parts of the world in different roles, for the simple, simple, simple reason that I don’t meet all the points. So something that I started to learn at a very early age, but that was reinforced, like every two or three years, is that you learn along the way, that you have to get out of your comfort zone to learn and grow and that you have to overcome your fears in order to do so. Because everything you seek and everything you long for will always be there.

[00:13:00] And more so because you were probably like many people applying and competing with men who don’t even have 10 percent and say they have 100 percent.

[00:13:09] I admire them and I admire them,

[00:13:14] But I don’t think it’s normal. I mean, I don’t think it’s necessarily about sex. It’s a little bit of society and culture and what you said that has led us to believe that certain jobs are for men and others are for women and it’s totally wrong. I’m so glad you broke, you broke a stereotype in the race and then you broke a stereotype at work.

[00:13:37] And then what happened was that after I was progressing well in the interview, which today is the part I told you, that I learned it at an early age, but it has been reinforced through the years when I said, hey, but Gladys, I have never managed people and I am a recent graduate, I am going to have 35 technicians in my charge, I mean, it did not fit in my head. And then the reason they wanted to hire me was to start up and build the first chemical lab in the entire Mattel system. And I said but me. I mean, how then the lack of confidence, the fact that one can learn along the way, to overcome that fear and obviously it was something that I longed for and that I wanted, so even with the fear I said yes, I’m going ahead and thank God the truth is that it went very, very well. Obviously we opened the chemical laboratory, there were other vicissitudes of terms there.

[00:14:37] Gender,

[00:14:38] They told me where is the how? Who’s to say where your dad is to negotiate, right? Because I was 21 years old at the time, but well, data and facts change the conversation in five minutes and make you focus on what you need to focus on and this one. And then I started to grow, to have more areas of responsibility within the quality area. That’s why I studied the Master’s Degree in Quality and Manufacturing, because I wanted to be competent enough for the other time.

[00:15:07] It happened that they ended up obviously hiring for that position.

[00:15:12] As I entered one year to two years, I was already having other areas under my responsibility and each year I was having more areas until I had everything that is the quality area. And then there’s the part about at that time it was new ISO 9000. In fact, there were no cash register companies here in Mexico.

[00:15:30] It was not the first company to open the laboratory of.

[00:15:35] Monterrey, globally, globally, globally, globally, globally. And then who was going to say hey, that

[00:15:41] Pride in being Mexican and in Mexico. Because that is the other side of the coin that one always expects to be opened in France, or in the United States or in Germany. The first was in Mexico,

[00:15:52] The things we have done proudly Mexican and in fact I was the first expatriate in Malaysia of the whole Mattel system, Nigeria and there it is. They didn’t even know the procedures, but well, we have known the gap in many things and they told me that now we want you to be responsible for the implementation of the ISO 9000 quality system in the whole plant and again. Hey, I don’t know anything about these. I didn’t, nobody knew who I was. Don’t worry, we know you can learn, you learn fast and you will succeed if you hide fears and we all go for

[00:16:31] That you also had very good bosses and mentors. I imagine that because on the one hand you are being brave and breaking stereotypes and paradigms and daring. And on the other side there has to be the counterpart that gives you the opportunity. And that already shows that Mattel has a very strong culture.

[00:16:46] Yes, I totally agree, very, very blessed, because although there were not many women in leadership positions, I always had men who were role models and who believed and supported me to continue growing within the organization and so I climbed up the ladder. Then came another opening, a plant opening, and four of the then managers were selected to be promoted to management, to open the plant. And General Narayen told me in Monterrey, in Monterrey, the general manager of the existing plant was going to be the general manager of the new plant or an American. So he said to me, “Hey Gladys, I want you to join the team, but I thought that in quality because I came from quality, I already had my master’s degree in quality. I also studied for a Master’s degree in Organizational Development because I realized

[00:17:41] That I had expected. You already skipped two, three parts there. At what time? What did you study?

[00:17:45] Two, and I had three children along the way.

[00:17:49] Well, like your dad, then you would fall asleep at 2 3 in the morning, all

[00:17:53] The days in 4 hours I slept with 4

[00:17:55] Hours are you fresh? Yes, that’s the secret.

[00:17:58] Now, now, I sleep more, I sleep more this one, but mostly the organizational development part, because I came from very technical areas. Then I realized with the ISO 9000 quality system, that you can have the best work system technically speaking, but if people do not accept it as a way of life and not as more work, but as better work, I began to understand the part of the people’s culture. I was passionate about all that and I think that was one of the success factors, right? Because mixing the human part with the technical part and technology is really a catalyst for the processes of transformation and growth in organizations. So that’s why I studied the Master in Organizational Development.

[00:18:48] And also for

[00:18:51] At ADM, at UNAM I studied it and at TEC I studied manufacturing and quality. Then Dan Dan Gilbert, who was the one who talked to me and said hey, we want you to be part of the team. I was super happy because I wanted to be at the opening of a new plant, because I saw it as a giant laboratory. To be able to put the best of the best into practice

[00:19:14] It is forgiveness. Let me interrupt you again that at this time Mattel is manufactured. What are Barbies?

[00:19:20] There are many, but not Barbies and Hot Wheels, which is part of the core business of manufacturing materials in Asia. That’s why I was there working

[00:19:28] What was the plant of

[00:19:30] That it was the plant. Mainly it’s Mattel’s accessories for Barbie, such as campers. The number one toy worldwide is proudly produced in Monterrey, which is the Barbie Dream House. These were made 100 percent in Monterrey for the whole world. So if

[00:19:49] Fun as a woman to work in a company that really your first product is good, you have the cars but you also have the Barbies. I believe that

[00:19:56] Yes. It is an environment

[00:19:57] Fun and a lot of fun for you.

[00:20:00] No, as soon as I set foot in the plant I said I belong here because I am surrounded by toys in the quality part. See the functionality, the durability, the safety risks and know that every piece of toy brings happiness to a home.

[00:20:18] Hey and your children who

[00:20:21] All the toys they had and played with the boxes.

[00:20:26] Like everything else, like all the children in the world,

[00:20:28] If they played with the toy boxes, then what about me? Gladys says to me, but we want you to be the director of Materials and then me in Choco, because I was saying

[00:20:41] The only thing you hadn’t studied was

[00:20:44] Production Planning, Master Planning in Development, Suppliers, Import Export, Warehouse Control of shipments,

[00:20:57] Eulogies totally another dimension. I am

[00:21:00] I stayed. I mean, I thought he was even wrong. And me, yes, I am of quality and you are offering me the position to materials management. And I told him, obviously I was very happy to be part of the team and to start. And of course I wanted to be there, but I tell you this Dan. I all my experience is in quality and this is a new area and it’s a startup plant this mess. You are aware that I don’t have the experience to do that. And Gladys told me something very important that I need you to be very clear about. I can go out to the market and get in the blink of an eye, well, maybe a hundred people who have the skills to do the job we are looking for. But for me the most important thing is two things is that they have leadership and they make things happen, or if you want to look at it as leadership that makes things happen and that’s not easy to achieve. Moreover, throughout your career you have shown that you are a person who learns and learns fast. Yes, then with what they told me, I got rid of everything and the fears. And besides, don’t worry, we’ll have a year to train you. So, with these issues, we go forward with all our fears and everything. So that’s where I started the part. That’s why I also studied at Thunderbird, in Arizona, the Master’s in International Business and interacted with

[00:22:40] With part of this capacity, etc. in the year.

[00:22:44] Yes, and then I started to open up to international negotiations, the logistics chain, commodity management. You know well because you’re in that industry, it’s huge, because everything you have to learn in the McEwen supply chain. But I was passionate about bringing the one engineering hat, the 2, the quality hat. Three, Organization and Development, as it was a successful bomb. Why? Because when you go to negotiate and look for opportunities with suppliers, I got to know more than 100 processes. It is then easier to identify opportunities to reduce costs, negotiate better and ensure quality and demand the quality you were looking for. So it’s all in out. This one helped me a lot,

[00:23:42] Very much

[00:23:43] To be a better negotiator, to ensure that innovations or cost reductions are not detrimental to quality and safety. And if we obtained this, then the cost benefits that the company needed and obviously put into practice everything that was in vogue at that time, that the direct line canvas, this BMI, this all of suppliers and start to bring suppliers that would come to relocate to Mexico.

[00:24:19] How interesting! It is very very complete your totally a school, a master’s degree in supply chains. How interesting! And they opened, they opened the plant successfully, I imagine us

[00:24:32] It went very well. And this plant and that it is also so as information

[00:24:36] There is at that time, because

[00:24:39] There was a lot of entrepreneurial talent from our principals. The main competitor is Hasbro and Lego are the main east. However, in the United States, we have been number one for thousands of years and Lego is doing very well right now, but worldwide for a long time as the number one player in the toy industry, especially in terms of quality, safety and product innovation and what we manufacture or the reason for this new plant, because it was a new plant in Mexico, was to bring us the U.S. operation. I was involved in many transfers, many openings, integration of new operations and new sharing or supplier localization activities. This at this time was the manufacture of Power Wheels. Power Wheels is one of our. Also iconic brands, electric detachable jeeps and is like the automotive industry in the toy industry. In fact, many of our protocols and we even share suppliers with the automotive industry. Within the toy industry there are also the protocols of the food industry, because we have for example Piqueras that have to be FDA, cosmetics, fabrics, clothing. So many people say ah, they are toys, but really the protocol of a toy is quite high because it is designed for the most vulnerable person, which is a child or a baby, who is not only going to use but also abuse the product. And that product, after being because we do drop programs, stretch programs, etc. has to continue to be safe even after abuse plus the additional protocols we have to put in place depending on the type of product. So the reason for opening that plant was for the automotive industry. In the toy industry, which is the ruins of the world, they are manufactured here in Monterrey and are exported.

[00:26:47] Narayen are still being manufactured to this day,

[00:26:49] They continue to this day. The reason we are also here is because our main market is the United States and Canada for Power Wheels. And because of the proximity and you’re talking about the size of the product, it’s practically a refrigerator. They are very, very large products. So you know, the cost of freight and transportation is impossible to bring it from Asia and then that’s where it came from. It’s good, there is a historical moment there, isn’t it? In the history of Mattel’s toy industry, well known by the media, in 2007 we had one of the strongest corners in the history of de de. It was found in one of the lead carts and this one. But it was in a monitoring of the Goodwill carts, in a monitoring that was done in our own labs and this one there. I was in the Supply Change area, at the opening of the plant. I was here in Mexico and this was happening in Asia and this we have manufacturing schemes, even with suppliers that manufacture the finished product and others with our own plants that manufacture the mate corvina. So this then is found. That was a voluntary record

[00:28:11] On the business side or was it on the

[00:28:13] What was in the year of the supplier supplier supplier supplier? What happened was that subcontracting was done that was not allowed.

[00:28:22] And that’s where the quality, the quality control moved a

[00:28:25] Little. Yes, so that’s where we start. This was made the voluntary record, we ourselves recognized the situation this was collected all of the

[00:28:38] A company, from everything you have told me, with a very, very strong culture, with very well-established values for

[00:28:46] Main unwavering integrity. And it was in those moments that we saw her in action, because many of the companies what you don’t see in a company is that you don’t

[00:28:55] They are hard to avoid