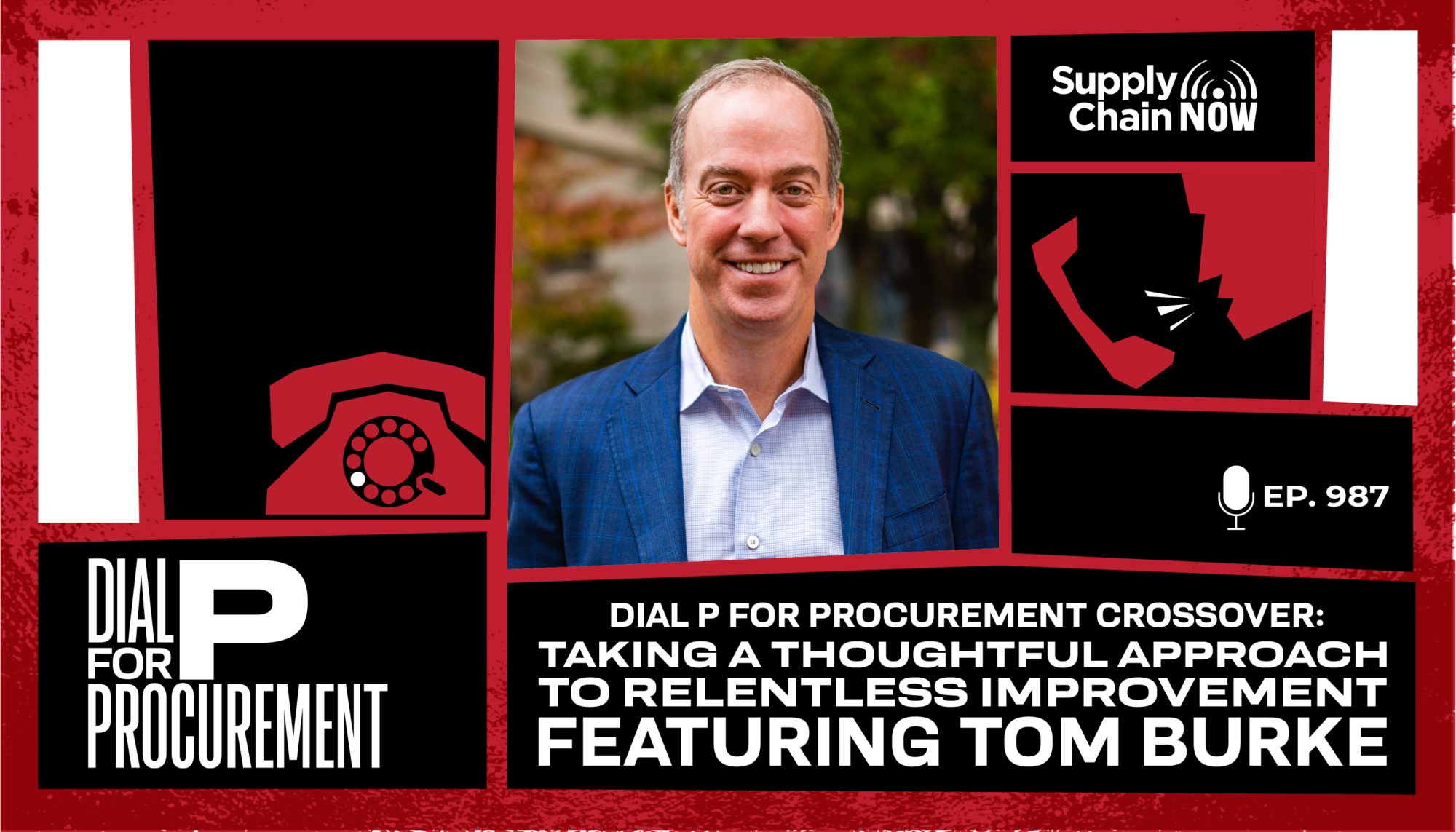

Nothing's ever perfect. But it's okay, because guess what? You get to wake up the next day and improve upon it.

– Tom Burke, COO of ButcherBox

Join Tom and Kelly Barner to learn more about ButcherBox’s core mission and vision for sustainable growth.

Episode Summary

Although the most memorable shortage of 2020 was toilet paper, there was a span of time in the spring and early summer when the food supply chain was under strain as well. Concerned about lockdowns and being able to feed their families, people bought huge quantities of groceries and stocked up their homes.

This kicked off a strong bullwhip effect, clearing supermarket shelves and creating shortages that reverberated through the supply chain to wholesalers and distributors.

ButcherBox is a Boston-based meat subscription service that delivers high quality meat and seafood directly to consumers’ homes. Demand for their services skyrocketed overnight, with thousands of people hitting their website hourly at the peak. As a self-described “member obsessed” team, ButcherBox had some important decisions to make. How fast could they expand? How would they protect their existing customer experience? How many people could they help while preserving their quality standards?

Tom Burke is the Chief Operating Officer at ButcherBox. He is responsible for technology, people ops, customer support, and finance. In this Dial P for Procurement crossover episode, he joins host Kelly Barner to talk about the choices he and his team had to make during the pandemic, what they have seen in terms of demand since, and what is on the horizon for their mission-driven company.

• What went into the decision to start waitlisting new customers in March of 2020, and how ButcherBox managed its growth during the surge

• How innovating to create fully recyclable packaging and making the strategic decision to purchase their own dry ice facility align with their value proposition and corporate culture

• What they have learned about the connections between sourcing high quality protein, supporting the farming community, and making lasting improvements to the environment

Episode Transcript

Intro/Outro (00:01):

Welcome to dial P for procurement, a show focused on today’s biggest spin supplier and contract management related business opportunities. Dial P investigates, the nuanced and constantly evolving boundary of the procurement supply chain divide with a broadcast of engaged executives, providers, and thought leaders. Give us an hour and we’ll provide you with a new perspective on supply chain value. And now it’s time to dial P for procurement.

Kelly Barner (00:31):

Hi everybody. Thank you so much for being here with me today. This is the monthly video interview, uh, dial P for procurement here on supply chain. Now I’m Kelly Barner, your host, and I am thrilled to be joined by a very interesting guest. I have with me, Tom Burke. He’s the chief operating officer at a company called butcher box. So hi Tom. Thank you so much for being here with me today.

Tom Burke (00:57):

Thank you so much for having me. I’ve been looking forward to it all week to get to know you and actually, um, have a great conversation.

Kelly Barner (01:05):

Excellent. Well, I will tell you, flattery will get you everywhere on this show. So you’re already off to a great start. Uh, we’re gonna get a little bit more into the company as you and I go through the conversation, but can you start by sharing a little bit with us about sort of your professional journey?

Tom Burke (01:22):

Sure. Um, I actually, way back when I thought I’d be a, a physicist at NASA and I was a undergrad, um, physicist and I graduated and realized NASA was not waiting and I went to become an accountant from a CPA. And I worked in KPMG for, uh, 10 years in Boston, as a auditor spent a couple of years over in Dublin Ireland, uh, taking companies public on NASDAQ and I realized I like startups. And so I left public accounting and my first startup was a biotech company in Cambridge back in 2001, I believe. And for 17 years I spent in biotech, um, startups, um, in a role of a CFO COO typed role. And as I was winding down my last biotech company in the end of 2000, uh, 2017 butcher box was, uh, introduced to me. My current CEO at the time was a mentor and friend of Mike L Darlan.

Tom Burke (02:22):

We were introduced, I could help him with a couple of questions. He was having around finances and getting a CFO. And one thing led to another and I said, Hey, we’re winding down my turn company. I might be looking for a job. He said, really? And we, we talked and I jumped in without really any meat background, a lot of startup background and definitely, uh, coming from an, uh, an environment where it was regulatory, uh, oversight, um, a very complex supply chain in and of itself. Um, whether you’re making a, a drug that’s made it to market or developing a drug. So there was a lot of synergies that kind of made it a little bit easier for me to transition to.

Kelly Barner (03:01):

Yeah. And you’ve mentioned meat. So for people that haven’t found butcher box, they’re gonna feel very differently by the end of this conversation. They will know a whole lot, but can you just tell us a little bit about the company and sort of the business model behind it?

Tom Burke (03:17):

Yeah. The, um, the company was started by Mike guiro back in 2015. He, he really just, he and his wife went on this journey of like, how do we eat better? And, um, they were looking into grass fed past raises beef, and the only way to get it back then was really to kind of go to local farms and then kind of coordinate getting some beef from the local farm. Yeah. There was a little bit of it in stores, but not at any level, if you, again, rewind seven years. Yeah. Um, and so as he was doing that, the thought came, Hey, wait a minute, there’s gotta be an easier way to get this to people than me driving up to Vermont or New Hampshire, which is like a two hour drive. And so he really started to focus on how do I build a, a supply chain around high quality protein.

Tom Burke (04:10):

And in this example, grass fed past raise beef. Um, that really was what we believe better for the individual healthier. Um, and so that’s what kind of kicked it off. And from there, you know, we started to think about, well, it’s not just beef, it’s chicken, it’s pork. And so we really started to kind of think about, okay, what does that supply chain mean? And when you, when you kind of unpack it, most companies say I need to build a widget and I’m just gonna kind of just go after it. Where we started was we want to provide high quality protein to individuals with animals that are humanely raised that are given the best environment mm-hmm <affirmative>, um, to grow. And that helps the farmer expand their market, you know, not from a little footprint, but from a, a bigger mass that they can get to. And as we unpack that it low and behold, you actually are also dealing with farmers that actually treat their, their farms and the environment in a way that actually regenerates some areas, but keeps it robust and healthy, um, as they continue into the future years. And so it kind of, as you went down, we were checking all these boxes that became our mission.

Kelly Barner (05:30):

Tom, I have both supply chain and procurement professionals as the core of my audience. Although obviously there are people representing other functions as well. I believe both supply chain and procurement are under your purview. Is that right?

Tom Burke (05:46):

Uh, that is right. I also happen to oversee, um, technology, people, ops customer support finance, and I, I always tell people it’s not because I’m the most knowledgeable in those areas. Um, rarely when I go into the room, I’m probably the least knowledgeable about the subject, but I’m there to help facilitate and kind of knock down roadblocks and having those different groups kind of roll up into me. I get to see kind of like, oh, we’re, we’re missing connecting, you know, between procurement and ops and logistics or procurement and merchandising. And it’s just getting people together and just kind of talking through where maybe the miss was, or more importantly, how we can actually help you as a company, um, you know, further what you’re doing or, you know, fix a problem.

Kelly Barner (06:37):

Yeah. Now it’s interesting that you have so many different areas reporting up to you. And as you mentioned, you’re not sort of hands on in the weeds with every one of those. No person could be. How does your background with startups, do you think help you facilitate all of that cross-functional collaboration and figuring out ways to jointly problem solve? Let’s say

Tom Burke (07:01):

I, I think my career, especially the startup world has taught me that, um, it’s okay. Not to, um, be the, the most knowledgeable and it’s actually okay to ask questions. And, um, I’m always asking the most basic questions. Um, I’m always telling people like take it down to an eighth grade level and I think we’ll be able to kinda get there. And so that coming into this company, obviously not having a kind of meat background or, um, a e-commerce or supply chain background, um, allowed me to kind of like really lean into the people that are amazing here that know so much, and that really want to bring all of their knowledge to the table. And I wasn’t blocking that by, by being open to everything. And by being able to ask questions, it allowed me to, um, understand what they were doing, but also understand where, Hey, I think I know where I can help you and kind of push things forward.

Kelly Barner (08:00):

Now, people probably don’t ask you this very often and, and people can cringe as they’re listening and, or watching later, but I’m actually going to say, would you take me back to early 20, 20? Let’s actually deliberately go back to that time and think about, so you’d been at put butcher box about three years at that point, it’s February, it’s March the wheels officially start to come off the global boss. What were things like for you and your team at that time?

Tom Burke (08:30):

You know, it’s funny. I was talking to someone the other day, you know, it feels like a lifetime ago. It does, and we we’ve removed ourselves, not for anything other than times pass and forget what that period of time was. And, you know, as I was thinking about this and when I was talking to, I think it might have been my sister, you know, there were a lot of things that probably all companies were juggling. We were really kind of, you know, thinking through this, there was our members, right? How do we actually continue to kind of support our members as we were coming out of February and into March. And as we were getting our head around what was going on with COVID, but there were other pieces that were also impacting us that we had to acknowledge we, as individuals were going through this, it wasn’t that there was a disruption in, in the world and the supply chain that only affected business.

Tom Burke (09:23):

This was the first time in my memory that every person on the planet was impacted. And so you had a kind of like juggle, like, okay, what’s going on in the business, what’s going on with you as an individual in your family, and then what’s going on with the employees. And so, as we were thinking of all this, we were trying to kind of like, like you were kind of phasing in and out to try to figure out how best to kind of navigate it. And I can remember, I actually was home March 11th with my younger son who had the flow legitimately had the flu. And four days later we were like, we’re closed, we’re done. And you know, it was around March 17th that like, that’s when the world really shut down.

Kelly Barner (10:08):

Yes. And it’s funny because you know, you and I both have our, our Boston connection. Um, and one thing that will always stand out to me about that particular March 17th was the drop kick. Murphy’s a very Boston, Irish hard rock band. Yeah. Doing this live stream St. Patrick’s day concert. And I can still remember the shock of, of that moment. Nothing felt quite right. There was so much uncertainty. And in fact, it’s, it’s that moment that’s actually part of what led us to that this conversation. Because in addition to being thrilled to know you and interested in the butcher box company model, my family is subscribers to your service. And we had originally probably about March 17th or the 20th somewhere in that area, tried to sign up for the service because we all remember the great toilet paper shortage of 2020. Yes. We’ll never forget that.

Kelly Barner (11:09):

Yes. But what people may not remember is that some food items became very hard to get a hold of and so services like butcher box. I’m sure the demand surge from your perspective overnight. And initially we were waitlisted to be able to get onto the service, which is something that as a supply chain professional, I respected. Um, and I’d be interested to hear your perspective from inside the company. That really tough choice of there’s now overnight, a bazillion people banging on our door, wanting our service. And of course you wanna grow as fast as you realistically can, but there’s that service quality customer experience element. And there has to be a supply chain to support it. So what did that look like from inside butcher boxing? What were some of the discussions and decisions that your team had to work their way through?

Tom Burke (12:08):

Well, first thank you for being a member. We appreciate it. Um,

Kelly Barner (12:12):

Oh yeah. And we love the bacon, so,

Tom Burke (12:14):

Oh, that’s great. <laugh> I do too.

Kelly Barner (12:15):

No suffering here. <laugh>

Tom Burke (12:18):

Um, you know, I think it goes back to what I was saying earlier. Like there, there were many layers at that time that you’re dealing with that you have to acknowledge, um, you personal. I, I have three kids, they were home. Um, you know, you’re dealing with employees and you’re dealing with, uh, you know, your members. And if we really rewind back then no one knew when it was gonna end. Yeah. In March in April, it wasn’t that, oh, on June 30th, we’re gonna be able to get out of our house. And so things were kind of like, um, you know, not showing up in the grocery store, toilet paper, some food products, cleaning supplies. Oh yes. Cause back then you were told, get cleaning supplies and then wipe down everything before it comes into the house.

Kelly Barner (13:07):

Yeah. Ly saw your mail, everything,

Tom Burke (13:09):

Everything, everything. And so, you know, really what we were dealing with. We don’t know when the world’s gonna open back up again. We have thousands of people coming to our website, almost in a, on a hourly basis looking to help them navigate this. And when we step back, we were kind of like, okay, as a human being, I’m just looking to provide food, continuing supplier food for my family. That must be what our members are feeling at this time. And they’re looking at us and saying, you know, Hey, I have a subscription with butcher box. They’ve always been able to pro you know, produce the, the product and deliver it to us. Um, we had members moving in boxes to get ’em sooner. Um, okay. And so we stopped and said, okay, there is a, a business decision. We could just keep signing up people and then we’ll figure out the supply.

Tom Burke (14:06):

But if we are true to our mission, which is member obsessed, one of our values, and if we’re gonna actually treat our members the way we want, which is like family, to some extent, you know, we need to be there for them. And so the play can’t be just sign up, sign up, sign up, sign up. The play has to be, let’s understand our supply chain. Let’s see where the, the pressure points are. Let’s see what we can make sure we can deliver how many members we can support. And then let’s put a wait list up when we know that we’re gonna be maybe at risk of not being able to support the members that have signed up. And so the, it wasn’t a hard decision. It was an easy decision cuz it was born out of yeah. You know, we really want to care for our members and we wanna provide quality protein.

Tom Burke (14:54):

We want to be there. And we wanted to not let them down at a time when everything seemed to be letting everybody down and not because people weren’t trying, but the world was just kind of shutting down. And so that, that really was the impetus of put the wait list up. We’re not gonna take it down until we can guarantee every person we bring in will be able to provide some protein to them. Now the wait list stayed up for at least three months. But even during that time, we would take some people in because we’d say, Hey, we can actually support a hundred more subscribers. So let’s take them in. Like let’s help them because they’re like us with their families worrying about this and maybe we can alleviate that. So it was a constant looking at it daily. Could we take in a couple of extra, how could we kind of make sure that that doesn’t impact, um, supporting the members we currently have? Um, so it was a, it was a unique time. I know we made the right decision as a, a member of butcher box as an employee, but also as just a human being. I, I think we, we did what we, we said we would do, which was be there for you.

Kelly Barner (16:07):

And, and I would agree with that even as being the person on the wait list, we were lucky. We weren’t waitlisted very long. And I can remember having the conversation because just as you and your team were looking at the situation as business decision makers and people responsible for analysis and managing supply relationships. I walked through that time, very much looking at everything on the one hand, as a parent who wanted to be able to feed my family, but also as a supply chain professional, you can never take that. Yeah. That perspective away. And I can remember very clearly thinking, okay, that’s an impressive choice, right? You, you get the business, the simplicity, like you said, but the high stakes of making that type of a decision. Um, the other thing, Tom, I wanna bring into this, cuz I think I’d be remiss if I skip this detail, I’ll take a stab at this.

Kelly Barner (17:00):

And then you can, you can fill in anything that I, I missed or correct me. So butcher box is a service and you have it on a recurring schedule. You log into the website and you have so many picks and you can use those picks for different cuts of meat. You can get multiple units of the same thing. If you want all chicken, you can have all chicken, right? You have different picks. Yep. And there’s some amount of flexibility around the scheduling. So for instance, when you talk about customers pulling their boxes in, if they were by default going to have an order come out, I’ll just say every four weeks they were making the decision to say, all right, I’ve adjusted my picks. I’m ready with what’s here. Let’s go at two and a half or three weeks. Let’s pull it in. So that I’m actually getting another iteration of delivery. Um, did I get all of that more or less? Right.

Tom Burke (17:52):

You were actually spot on that’s exactly what people were were doing and the activity and, and the other thing to remember for your listeners butcher box, we deliver our, our protein frozen, right? So it comes to you frozen and you can put it in the freezer. And so if you think about that time and the uncertainty of like, what would may bring, what would June bring when people were making decisions back in March and April being able to provide me on a consistent basis? Yes. That was frozen. You could store you like that was another, um, thing that drew people to butcher box. I think the, the pulling in of the box where, Hey, I was gonna get it on April 30th. I, I want to get it on April 1st because I don’t, I don’t know what’s gonna happen on April 30th. And so you had this, um, increase in people signing up and this increase in boxes being shipped earlier.

Tom Burke (18:47):

And that was a complicated calculation to try to understand then, okay, how does that all flow with the product we have in the facilities? And then what’s going on in may. And also the other factor was just dealing with our partners, the fulfillment centers, the suppliers, because again, they were human beings going through this and it wasn’t not affected them. And so how does it affect the people that are actually helping us deliver it to our members and working closely with them so that those employees and people were being protected and treated as best they could, as we were all navigating this.

Kelly Barner (19:23):

And, and in addition to having the flexibility around what you get and when, and the surety of that supply, there is also the factor that it’s being delivered directly to your home. So sort of an added value proposition it’s coming in frozen. So as long as you have the freezer space, you can hold onto it for as long as you feel like you need to hold onto it. But you’re also not going into the store, which was something that was raising a great deal of concerns back in those early uncertain days.

Tom Burke (19:53):

Right. And again, remember masks, weren’t the, the thing back then, that’s, if you were going out, um, don’t use a mask, use a band in or cover your mouth, but like, you know, because again, they were trying to navigate their own supply chain of the health, you know, supplies to get ’em to the hospitals. And so for us, that was a added benefit to the member of like, you, you don’t at least have to leave the house for this. Or if you have to go into the grocery store, we can shave off 10 minutes of your time in there. That’s right. Because you don’t have to worry about the protein. And I think it was a combination is a great column on your part. It was a combination of that. It’s frozen. Um, the meat is high quality. We have a, a, um, a history of supporting our members. I think our brand has always been especially back then. Um, wow. They just always have lived up to what they’ve said. And, and that was really important part. There were our companies out there that were just trying to grow because that’s the decision they made, whether right or wrong. And then after the fact, they were having to tell people like, Hey, we can’t get it to yet, you know, it’s gonna take time and we never wanted to be in that spot as best we could.

Kelly Barner (21:03):

Yeah. And that’s even something that we would hear about in the B2B space. You would think you had finally secured a lo a load of gloves or masks, and you’d put the order in and then you’d find out it wasn’t actually coming. And the confidence shake of that I think is, is certainly something that, that people carry with them still to this day, I think continues to impact how we personally, and from a corporate standpoint, manage our inventory.

Tom Burke (21:31):

Uh, absolutely agree. And I think our members, um, during that time, uh, were so appreciative of what we did and appreciated that we were there and didn’t go away. And that we did make that decision, um, that we were there for them. And as we could, we would bring new people in. Because again, back that, back in that time, no one knew when it was gonna end.

Kelly Barner (21:55):

No, and yet, fortunately, I don’t know that we will ever say it has ended. Right. Sort of like the great depression once you lived through it. It’s, it’s part of who you are forever. And we have fortunately reached endemic stage, which has at least allowed the return of some type of normalcy. But I’m curious to hear what the time, maybe since fall of 2020 to where we are now has been, you know, I think even as consumers, we’ve watched some companies that were the absolute must have during that pandemic time kind of fall by the wayside, their value proposition, isn’t the same as people left their homes again. And yet other companies managed to either pivot or maintain that loyalty and continue on their growth trajectory without losing stem. Where would you put butcher box on that continuum?

Tom Burke (22:49):

Uh, we definitely have been able to continue to grow and, and, um, not miss a step. I, I would say that we all stumble, um, whether it’s in our life or running a company. Yes. But we’ve been able to continue to grow and to continue to be there for our members. And I think it’s because we’ve always been consistent with what we were trying to do, which was at its core, provide high quality protein to the individual and not, not be fancy, just get it to the individual. I think as we’ve gone through the past somewhere years, what we’ve been able to do is unpack even more why individuals like us and, and, and what’s special about us. You know, I alluded to at the beginning, you know, it was about getting, you know, grass fed pass, raised beef, you know, easier and more accessible to individuals.

Tom Burke (23:39):

But as it evolved, you start to kind of see the, the knock on effect of that like, oh wow, we can actually help farmers that actually love to raise animals a certain way. We want the animal animals to be humanely raised. Um, and as we kind of dove deeper and, and really started, you know, unpacking the, you know, peeling back the young in, so to speak, yeah. You start to see the benefits of that in the environment. And so, as we evolved, it was like, oh wow, these, these things are becoming even more real. And we can actually explain them to our members. And so the members that maybe joined, because they weren’t sure what was gonna happen in March of 2020, they started to get on the journey of butcher box and said, oh, wow. It’s not just about being here for me during this pandemic.

Tom Burke (24:26):

Yeah. Like they’re really raising the, you know, the bar on, you know, protein and claims and wanting to help us eat better. And as we got to know our members more, it was what kind of jobs are we servicing for them? Oh, we’re providing, they want to eat healthy. We’re getting that for them. They wanna learn how to cook things. We we’re able to kind of start to supply that we’re able to be a convenience for them. You know, I have three young boys, my wife and I both work. We’re running around all over the place. It’s like, oh, but we don’t have to go out and worry about getting the meat it’s here. And in the busy life that we have, that’s a, an important part, the convenience. And so over the years, the members that joined back then have been on this journey as we’ve kind of continued to like learn and express more about what we do and what we wanna do and how we want to help individuals and try to meet them where they need us.

Kelly Barner (25:23):

I’m sure there were many observations and lessons learned that you and your team took away from, let’s say the critical time of the pandemic and then sort of the gradual easing that followed if, if you were to have sort of a virtual imaginary whiteboard with all of those ideas on it, can you talk a little bit about how the approach has been to prioritizing, um, either figuring out what new to bring in? So you mentioned cooking tips, right? That’s a new idea. Um, but then even new approaches to connecting with existing and target customers from a marketing standpoint, how have you figured out what should be done first, um, and sort of relatively ranked things in terms of their ability to allow butcher box, to continue to grow.

Tom Burke (26:09):

Yeah. And there’s, there’s, there’s actually multiple ways to look at that. You know, one is from the environmental friendly, um, you know, the, the easiest one was like dealing with our box. Another one was, you know, in talking with our members and getting to know them, like, what, what more would you like? And what we found was, Hey, we want variety. You know, we love the, be the pork chops are, are amazing. The chicken nuggets are awesome, but can you take your meat and produce other things? We release meat meatloaf during the summer, we just released meat, uh, meatballs. We have, um, you know, at the time, you know, we, during that, between the pandemic and probably a year, you know, we were rolling out even more, um, freshly caught Sockeye salmon. We added scallops, we rolled out lobster from Maine and it was all with the desire of like our members want more, um, you know, protein and, and, and meat that meets their health claims, but actually services other parts of their pallets and other desires to cook. And so that was a big push and it’s continuing to be an even bigger push as we kind of go through this year with, I believe about seven new products that are gonna kind of drop, um, over the next several months.

Kelly Barner (27:31):

Well, I promise to eagerly, wait for those and, and try them all as they come out. We’ve talked about sustainability. A couple of times, you’ve talked about sort of quality of life for the animals. We’ve talked about some of the, the process and the environmental concerns around where those animals live and, and certainly quality of life for the, the farmers and producers that are running those facilities. But I also think many of my supply chain Watchers will be interested in your box. So in a dial P first, I have a prop, this, I love it, love it. This is my, my lovely butcher box. I promise there’s not actually meat in here right now. I wouldn’t be able to lift it. <laugh> if there words very heavy when it comes. So it’s, as you mentioned, the meat comes frozen and packaged and there’s dry ice, but it’s a cardboard box. And there’s a, a, I don’t know the word for it. It’s sort of like a, a soft composite cardboardy thing that wraps around inside. I’m sure there’s a more technical term for it than that.

Tom Burke (28:31):

I’ve used that term quite a bit. That’s a great technical

Kelly Barner (28:34):

Term. The recycling thing. Yeah. Um, that sort of serves as an insulator, uh, but at the end of the day, you open it and of course, step one is you put the dry ice in the kitchen sink and you hit it with water and it makes your kitchen Okie spooky, which is really fun if you have kids. So that’s bonus number one, but then the entire thing is recyclable. Did you start right out of the gate having a fully recyclable, uh, shipping container that you were able to use to safely move this frozen meat from your distribution facilities to homes, or was that part of butcher Box’s evolutionary journey?

Tom Burke (29:10):

It was definitely part of our evolutionary journey. I think, you know, we have a, um, some key values that we live by at our company. And my favorite one is relentless improvement. And that doesn’t mean, Hey, work 24 7. You know, it means nothing’s ever perfect. Yeah. You know, it’s okay. Because guess what? You get to wake up the next day and improve upon it.

Kelly Barner (29:31):

Yes.

Tom Burke (29:32):

And, and we have a saying here, um, and I, I, I know it’s, uh, it’s, it’s one I use, I I’ve probably, um, copied it from someone else. That’s much smarter crawl, walk, run, right. You don’t have to be running out the gate. If you just start to crawl, you’re gonna learn a lot. And that, that in that learning, you’re gonna then learn how to stand up and start to walk. And in that learning, you’ll learn how to run. And so when we started, the company might just wanted to, to start to get grass fed past your beef out. He wanted to start to kind of like, um, almost like tell people about it. It was kind of in the background back then, but he’s like, this is important. This is better meat. This could really be healthier for you. And so it’s like, let’s just get it out there.

Tom Burke (30:16):

And originally we were in styrofoam, um, boxes, which to this day is a, a lot of people use, right. It contains the cold. Yeah. It can keep it frozen. And we, we, we said, well, let’s just get it going. We know we want to be better for the environment. We know we want to kind of help. Um, you know, people meet the needs of like, Hey, I just don’t wanna have the styrofoam box and throw it away. And so, as we evolved over the earlier years, it was like, okay, let’s get a, a cardboard box, but it wasn’t ideal. And there were other things we had to do to it. But again, now you’re starting to walk. And over the years, we’ve, we’ve modified and worked with our partners to really create a box that is, you know, curbside a hundred percent recyclable. Yeah. That, um, retains the cold, you know, what, what some people don’t appreciate.

Tom Burke (31:06):

We ship to every state in the continental United States. So we’re not a, a small regional company. You know, we ship from the east coast to the west coast, from the south to the north. Um, and we get there within one to two days. So it, it’s a, it’s a big logistical challenge that I think we handle great. We have an amazing team that does that, but the box has really been the, the game changer for us, because we can really say, Hey, we’re giving you a product. That’s better for you. We know it’s better for the farmer and, and the environment, but we’re giving it to you in a way where you’re not, you can just take that box, put it at the curbside, it will get recycled. And you can feel good about that.

Kelly Barner (31:50):

You know, and even if I were, we’ll pretend for a second, I was a horrible cold-hearted individual. And I said the heck with the trees, you know, doesn’t matter, it’s expensive to throw things out. Yes, I’m in central Massachusetts, we have to do the thing where you buy your pay to throw bags. If I had a massive styrofoam thing coming every month that I had to pay to throw out that changes my perception of the cost of the service. And so being able to, I mean, two minutes break it down, the whole thing goes out and the recycling, um, but figuring out where to develop expertise of your own versus where to partner, I believe you also own your own dry ice facility.

Tom Burke (32:32):

We do. Yes.

Kelly Barner (32:33):

So interesting. Where did the decision come to say, you know, we wanna own and run our own doesn’t necessarily seem like an obvious core competency when your focus is on the meat. What’s the strategic thought around running your own facility for dry ice?

Tom Burke (32:50):

I like to say it was the childhood dream of mine, but, uh, that, that was

Kelly Barner (32:55):

So you’re with me on the Oky. <laugh>

Tom Burke (32:57):

Exactly. I’m like, oh, we can, Halloween will be a hit at our house every year. Um, I think it was again probably, well, there were two reasons. One was a, you know, your natural business, like evaluation of like, Hey, we’re growing the company. Yeah. As we think about it, what, what makes sense in maybe owning a bit more of the, the supply chain that helps us deliver the box to the door? The other part of it was, you know, we made that decision as we came out of, um, the summer of 2020. And again, if you rewind, right? Yeah. Wow. There’s a vaccine on the horizon. Right. And if you, if you remember those conversations, the, uh, and this is where my biotech experience helped us as we were navigating some of this. And, and I pulled on some friends in the, in the industry, uh, the Pfizer and the Moderna were both gonna have to be shipped at minus 20.

Tom Burke (33:51):

I think one of them was minus 80. And as, as you’re coming out of the summer, it’s like, oh my God, this vaccine’s gonna have to go everywhere in the country, let alone the world. And it’s gonna have to be frozen and dry ice is the, the, you know, the choice of most biotech companies, pharmaceutical to Shipp things. Um, and so we were looking at it and say, well, we need dry ice. It it’s what actually keeps the, the, the protein frozen in the box. And so as we navigated that, we said, well, we wanna own a little bit more of our supply chain. Um, dry ice is a strategic thing that we need in order to deliver the box owning that de-risk us, but with the looming, um, vaccines, we, we, we needed to be able to make sure that, you know, we could have the dry ice because obviously we wanted the vaccines out there as quickly as possible.

Tom Burke (34:44):

And of course we were waiting for it, but we knew that people were also waiting for our food. And again, this was a time of up and down when people could leave their house, couldn’t leave their house. Um, and so really it was the business desire to own a little bit more our supply chain. And de-risk coupled with, you know, other people used dry ice and the, the vaccines were one obviously important example, but you know, other people ship and so owning that allowed us to kind of own a bit more of the control of a very important part of our process.

Kelly Barner (35:18):

I think what actually take away from that from a procurement point of view is really taking a big picture, look at what is actually strategic spend. So it would be very easy for you to say, oh, well, it’s the meat, or it’s the box, right? And each company is going to look at potentially the exact same products and services in very different ways. You know, one example that often comes up in conversations is if, if you have a warehouse and that’s the business that you run yeah.

Kelly Barner (35:50):

You know, landscaping, uh, probably not strategic, but if you own a bank with a lot of ATMs, how your customers perceive the safety and the cleanliness. Yes. And how cared for those ATM locations are, okay. Now you’ve taken the exact same service and you’ve repositioned it as strategic. And so I think that’s a great reminder to all of us to be looking at not only how important is something to your business, but who else uses this and how can we ensure that no matter what we have, what we need to keep our operation rolling. I think that’s another one of those great lessons that many decision makers took out of the pandemic that they wouldn’t have wouldn’t have come across otherwise.

Tom Burke (36:35):

No, I agree. And I think that like the default would be to immediately think of the protein and the, and the meat or the box, or, you know, further downstream owning supply of our, even more of our meat process. And, you know, at the end of the day, when you step back, it’s just it without the dry ice, that was gonna be a challenge. And it, it also allowed us to kind of in a very thoughtful way, take a step into owning more of our supply chain. Um, yeah. And, and that allowed us to get some learnings from that again, for walk run, it allowed us to kind of take something that we then could apply to other parts of our supply chain and start to really be strategic about how we’re allocating our resources, um, and the ROI we were gonna

Kelly Barner (37:23):

Get now, as you and I have talked through all of this, Tom, I certainly hear a great deal of empathy from you, for employees, for customers, for people who want to become customers. And I’m gonna go out a limb and assume that you would take that same type of approach to working relationships with suppliers. Um, and yet as you and I talk in early September, some markets are starting to see a shift for the last two and a half years or so. It’s been very pro supplier from a corporate procurement standpoint. They’re hard to replace. Uh, we wanna be customers of choice. They’re incredibly important to us, but with inflationary pressures and people looking really with a hard eye at the bottom line, some companies are starting to move away from that a little bit, maybe turn the screws in an old sort of bottom line, cost driven standpoint. What is butcher Box’s approach? What you say, actually, let’s say this, what would you say is the philosophy to how you manage those supplier relationships in, in good times in tough times, just sort of the general guiding philosophy?

Tom Burke (38:33):

Sure. I, I, I mean, obviously we’re a profitable company we’re privately BA owned. We, we never been, uh, never taken money where we’re not BC backed. Um, so profit’s important to us. Um, but what’s more important is our mission, our values and finding people that actually align with that. I think in some ways that’s part of the secret sauce, you know, there’s always gonna be bumps in the road. There’s always gonna be challenges, whether it’s a pandemic or a truck doesn’t come, or God forbid a storm happens. Yes. And you know, you lose power. And in those times it’s not that your business partners in those times, it’s that you guys, the people that are working together are on the same page and it’s all predicated on how they, how they handle their employees, how they think about our members, how they view their values.

Tom Burke (39:31):

And so for us, it starts and ends with finding suppliers, partners that actually share our kind of vision for the, the, the spaces that we’re trying to grow, whether it’s grass fed pass, raise beef, or, you know, freshly caught salmon, but more importantly, how to treat the employees, how to actually give a great experience for the member. And if, if you do all of that, you’re all winning because the business is growing and you’re all kind of now we are all looking for, how do we save at a time when conflations going up and prices are going up. And again, you know, at least you can have honest conversations with people. Yes. Because they know you, they know the, the baseline that you operate from and that, okay, how do we make this work for everybody? And, and those are conversations that are always ongoing, um, trying to make it right for the partner, for us, for the, ultimately, for the member. And, and it’s never easy and it’s always challenging. And maybe you don’t get it completely right all the time, but I think we’ve done a pretty good job. Our we’ve we’ve, we, I would say, have amazingly strong partners that, um, have never wavered from us and were there when we were growing with members during the pandemic and are still with us now.

Kelly Barner (40:52):

Yeah. Now clearly butcher box is a values driven company, and I’m sure you always have sort of the next initiative ready to roll out. I wanna give you the opportunity to talk a little bit about forward looking vision, you know, as general or specific as you want to be. What are some of the next things that as a team, as a company, as a brand, even in the marketplace, you’re looking at taking some of the, the opportunities you’ve earned by being operationally solid and being able to place a couple of chips, maybe on some things that give you an opportunity to invest in things that are important from a, a brand and community standpoint. Um, can you talk forward looking a little bit?

Tom Burke (41:38):

Yeah, I think, again, it, it starts with the member for, you know, in driving some of the decisions. You know, one of the things that we’ve just launched, um, in our, our brand campaign is actually trying to meet the member with, at the dinner table. You know, at the end of the day, we’re providing protein that you’re gonna be eating. And I think what we appreciated, especially as we continue to get to know our members, it’s how do we help them have that dinner that they want, whether it’s with their family partner or just, they’re having a quiet moment at home and they can just make a dinner for themselves and trust that, wow, this is really good for me and the people I’m I’m meeting with. And so we’ve really started to push how to, how to help them with that, how to help them have that dinner.

Tom Burke (42:27):

Um, how do we give them recipes to kind of help cook the protein that they have maybe in a different way, support them in that? I think the other thing is, you know, people do want, um, variety from us. And so a, a, a big push over this past year was continuing to look at that and trying to meet the members with, uh, product that they desired such as the, I mentioned the meatballs, which just launched today or a couple of days ago. So if anybody’s out there that loves meatballs. It’s great. It’s, it’s, it’s delicious. And it’s from our, our own, um, high quality meat. I think that’s where we start and that’s where we focus on. And then, you know, we carve out time for kind of the true business operations. And, you know, we talked about the dry ice facility. We’ve talked, talked about how we’ve optimized the box.

Tom Burke (43:18):

You know, we now are starting to kind of think strategically, okay, what is the next thing in the supply chain that we could kind of maybe get involved in that one allows for us to maybe reduce costs, um, but also allows us to kind of like be able to deliver a better product to the member. And, you know, so there are strategic conversations about like, Hey, in two or three years, what should we be getting involved in? Um, and that never goes away, but it, it is a, a balancing act because ultimately we want to be there for the member immediately with what their needs are. And so how do you kind of do that while think three years down the road?

Kelly Barner (44:00):

So obviously the journey continues. Um, and actually it’s funny, I mentioned it’s early September. It’s literally the Friday of labor day weekend. Yes. And so I can say, I know in my house we have a smoker in the backyard. Um, one of the hard things about having a smoker is that they’re typically intended for you to smoke an entire side of beef. At the same time. I don’t have that many friends, like as much as you love to smoke, you end up with sort of the Fred Flinstone pack of ribs. Hey, you take the butcher box stuff. You can do three kinds of meat because it’s not an entire side of cow that has to go on the smoker at the same time. Um, I’ll put in a pitch for dish washing services, if there’s a way to

Tom Burke (44:43):

<laugh>

Kelly Barner (44:43):

Follow aftermarket.

Tom Burke (44:45):

Excellent. I, I, I dishwasher loading. Yep. That’s great.

Kelly Barner (44:50):

Yeah. Um, no, but I I’m glad Tom, that you were willing to join me and talk about this because I think not only is this a category of product that we’ve all had a personal and even emotional response relationship with over the last couple of years, but I love the startup journey, the tough choices that you’ve had to make, how you’ve brought all of these different functions together. Um, and, and ultimately, I think there’s a lot for people to learn from this, regardless of what market they happen to work in. Um, and so as we wind on our time, I’ll sort of ask you two things. Um, one is, do you have any final thoughts, things that you’d like to share? What, you know, you personally took away from this, you from a business perspective, took away from the last couple of years, and then as you finish, if people would like to get in touch with you to learn more about your journey, to learn more about butcher box, where would you recommend that they go?

Tom Burke (45:51):

Um, great. Thank you for the opportunity first, thank you to, um, our members out there that have, have, uh, gone on this ride. Um, it, it definitely wouldn’t be as fun without them. Um, and really think what I’ve learned is we have an amazing company full of just amazing people that are open to asking questions too, that will give you their, give you their time, their support. And I found that as we’ve gone through the years, um, it’s those relationships it’s having those people. Um, the people that believe in the mission that love our values and actually just love working and hanging out together, that’s made it enjoyable and actually have allowed us to actually navigate this crazy time. Um, and, and given us opportunity to kind of maybe stumble. Um, but, but in the end, get it right. Um, and obviously if, if anybody wants to reach out to me, they can, um, my email is Tom butcherbox.com. So I’m happy to get back to anybody. Um, I’m also on LinkedIn. Um, so you can mess me, message me there. Um, but this has been a, a great opportunity. I I’m so appreciative of you, um, finding time and allowing me to come here and, um, have a discussion about like what, what an amazing company I get the benefit of working at.

Kelly Barner (47:18):

Absolutely. And, and those are the kinds of stories and journeys that, that we try to feature here on dial P for procurement. Um, so Tom Burke, chief operating officer at butcher box. Thank you so much for being with me. Thank you as well to everybody who’s joined us, either listening in or watching the full video of this conversation. Um, uh, one last time, seriously, nothing unites like a good meal, check it out, join the conversation. If you have questions, if you have additional thoughts, if you had a similar experience with a company over the last couple of years, whichever social media platform, you found this conversation on that’s the right place to put in your comment. We want to hear from our audience. So on that note, I’m Kelly Barner host of dial P for procurement here on supply chain. Now, thank you so much for spending the last bit of time with us and as always, I wish you a great rest of your day.

Intro/Outro (48:14):

Thank you for joining us for this episode of dial P four procurement, and for being an active part of the supply chain now community, please check out all of our shows and events@supplychainnow.com. Make sure you follow dial P four procurement on LinkedIn, Twitter, and Facebook to catch all the latest programming details. We’ll see you soon for the next episode of dial P four procurement.

Featured Guests

Tom Burke, As ButcherBox’s Chief Operating Officer, Tom oversees operations, finance, legal, customer support, and food safety. Prior to joining ButcherBox, he spent 14 years in the healthcare and biotechnology industry at companies like Hydra Biosciences and Infinity Pharmaceuticals. Tom started his career at KPMG, in roles both in the Boston and Dublin, Ireland offices. He received a B.A. in Physics from the College of the Holy Cross and earned his M.B.A. and Masters in Accounting from Northeastern University. Tom, a Certified Public Accountant, lives in Dover, MA with his wife and three sons. His favorite cut of meat? A ButcherBox ribeye. Connect with Tom on LinkedIn.